SMA (shape memory alloy) alternate drive device and method for vibration active control of sensitive structure

An active control and alternating drive technology, applied in computer control, program control, general control system, etc., can solve problems such as low natural frequency, dense mode, small damping, etc., to improve dynamic response speed, reduce thermal hysteresis, The effect of suppressing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

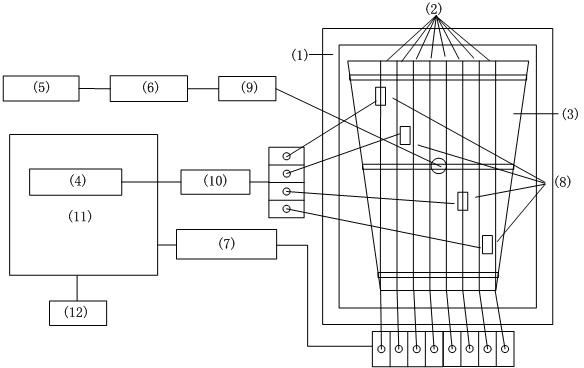

[0030] see figure 1. The shape-memory alloy driving device for the active control of the vibration of the sensitive structure includes a fixed support frame (1), an experimental model structure (3) equipped with a multi-channel shape-memory alloy driving unit (2), and an A / D data acquisition card (4), an arbitrary function signal generator (5), a signal power amplifier (6), two multi-channel alternate driving constant current sources (7), a set of multi-group PZT sensor networks (8), a An exciter (9), a plurality of charge amplifiers (10), a high-performance computer (11) and a digital oscilloscope (12), are characterized in that the computer (11) alternately drives a constant current through two multiple channels The source (7) is connected to the multi-channel shape memory alloy drive unit (2), the computer (11) has an acquisition card and is connected to the digital oscilloscope (12), and the A / D data acquisition card (4) is connected to the multi-channel charge amplifier...

Embodiment 2

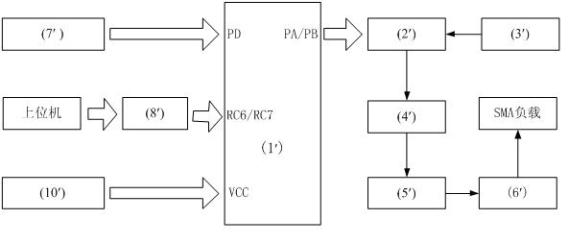

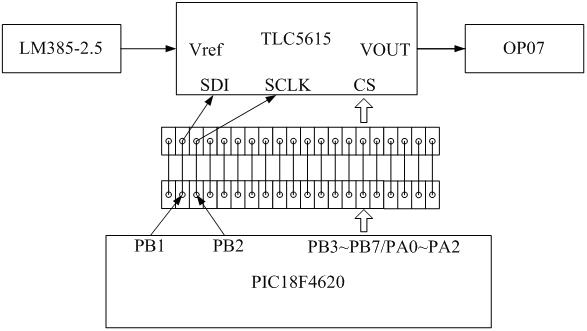

[0032] This embodiment is basically the same as Embodiment 1, and the special features are as follows: see figure 1 with figure 2 , the multi-channel alternate driving constant current source (7) is composed of an instrument shell, a single-chip microcomputer (1¢) and peripheral circuits. The instrument shell is provided with a front panel and a rear panel, and its front panel is provided with four constant current source output interfaces. And LCD display, the rear panel is equipped with power interface, fan equipment, and serial 485 communication interface; the single-chip microcomputer (1¢) and peripheral circuit: a PA / PB pin of a Microchip company's PIC18F4620 single-chip microcomputer (1¢) The D / A conversion chip TLC5615 (2¢) and the reference voltage chip LM385-2.5 (3¢) are connected to form a digital-to-analog conversion circuit, and an amplifier OP07 (4¢) is connected to an amplifier and follower circuit, and the amplifier OP07 (4¢) ) through a TI company power ampl...

Embodiment 3

[0034] Such as figure 1 As shown, a kind of SMA alternate driving device with active control of smart structure, the inventive device is mainly composed of a fixed support structure (1), an experimental model structure (3) equipped with multiple SMA driving units (2), an A / D data acquisition Card (4) (model: PCI-1712, manufacturer: Advantech Technology Co., Ltd.), an arbitrary function signal generator (5) (model: Angilent-33220A, manufacturer: Agilent Instruments Co., Ltd.), a signal power amplifier ( 6) (Model: YE5872 Production unit: Jiangsu Lianeng Electronic Technology Co., Ltd.), two multi-channel alternating drive constant current sources (7), a set of multi-group PZT sensor networks (8), a vibrator (9) (Model: JZK-10 Manufacturer: Jiangsu Lianeng Electronics Co., Ltd.), multi-channel charge amplifier (10) (Model: YE5852A Manufacturing unit: Jiangsu Lianeng Electronics Co., Ltd.), a high-performance computer (11) (Model: I500-7255 production unit: Founder Technology G...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com