Ultra-high power transformer

A power transformer, ultra-high technology, applied in the direction of transformer/inductor cooling, transformer/inductor coil/winding/connection, etc., can solve problems such as transformer overheating, transformer thickness increase, coil thickness increase, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

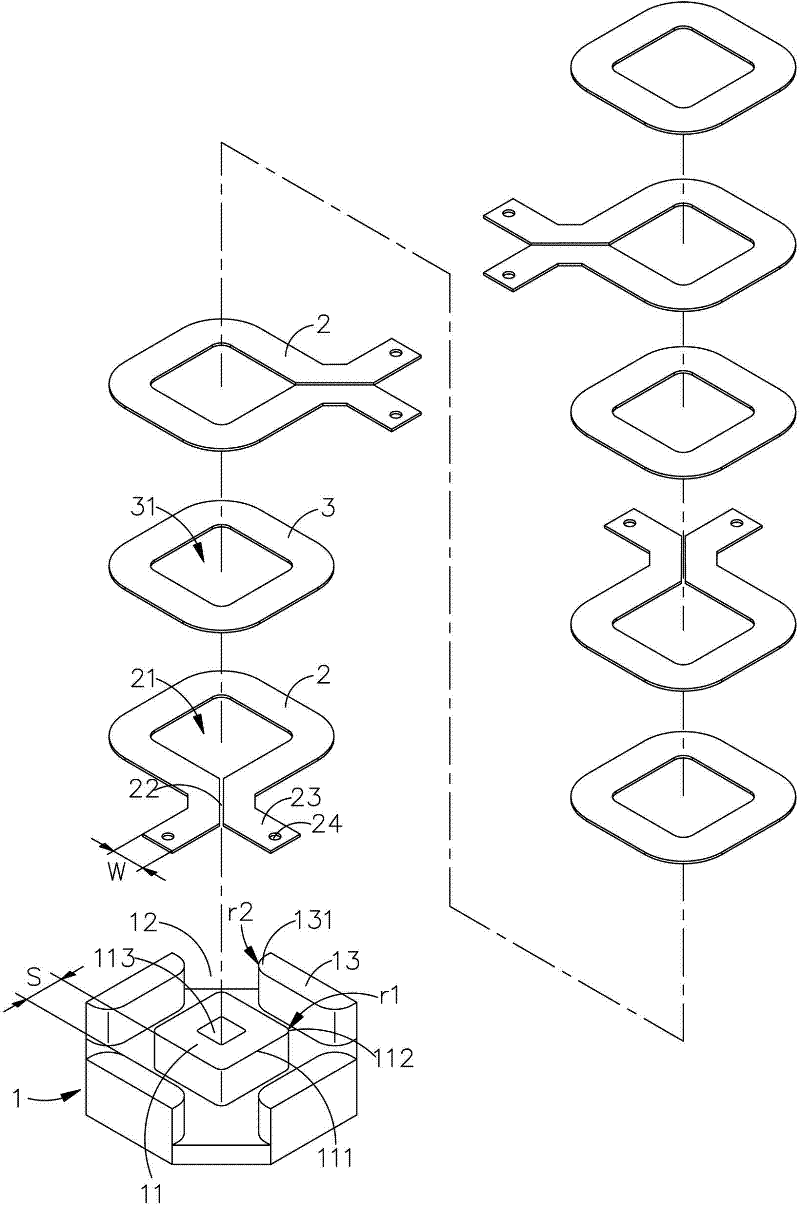

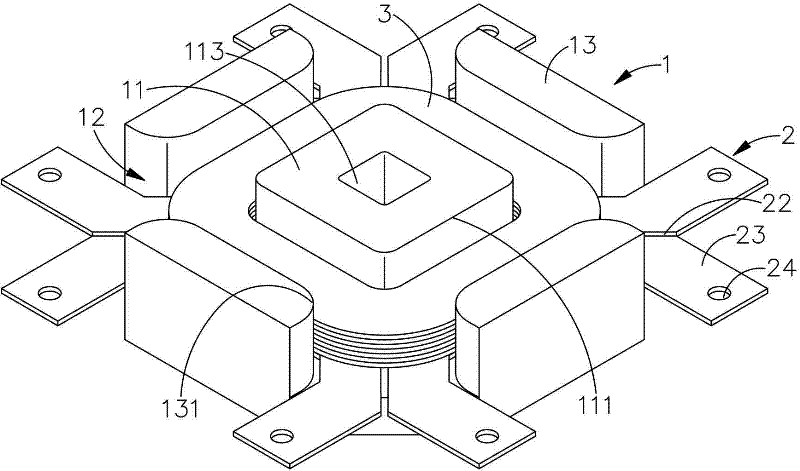

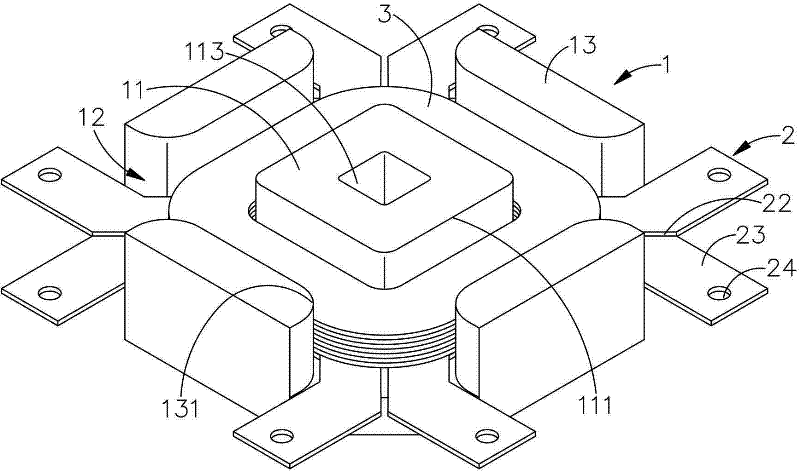

[0013] see figure 1 and figure 2 As shown, it is a schematic diagram of the three-dimensional structure decomposition and assembly of the preferred embodiment of the ultra-high power transformer of the present invention. The ultra-high power transformer of the present invention includes: a base 1 , a plurality of sheets 2 and a plurality of barriers 3 .

[0014] The base 1 further includes: a main core 11 , a plurality of slots 12 and a plurality of side wings 13 . The aforementioned main core portion 11 is a polygonal shape. In a preferred embodiment of the present invention, the aforementioned main core portion 11 is a square shape. Of course, this main core portion 11 can also be other such as pentagonal or hexagonal, etc. Changes like this can be implemented by those who are familiar with the art according to the above description, so they do not depart from the gist of the present utility model, nor depart from the spirit and scope of the present invention, so no more ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com