Gas spring for sliding refractory gate valve

A technology of gas spring and gate valve, which is applied in the direction of spring, spring/shock absorber, shock absorber-spring combination, etc. It can solve the problems of large applied force and failure to allow the sliding mechanism to work, and achieve compact design and prevent leakage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

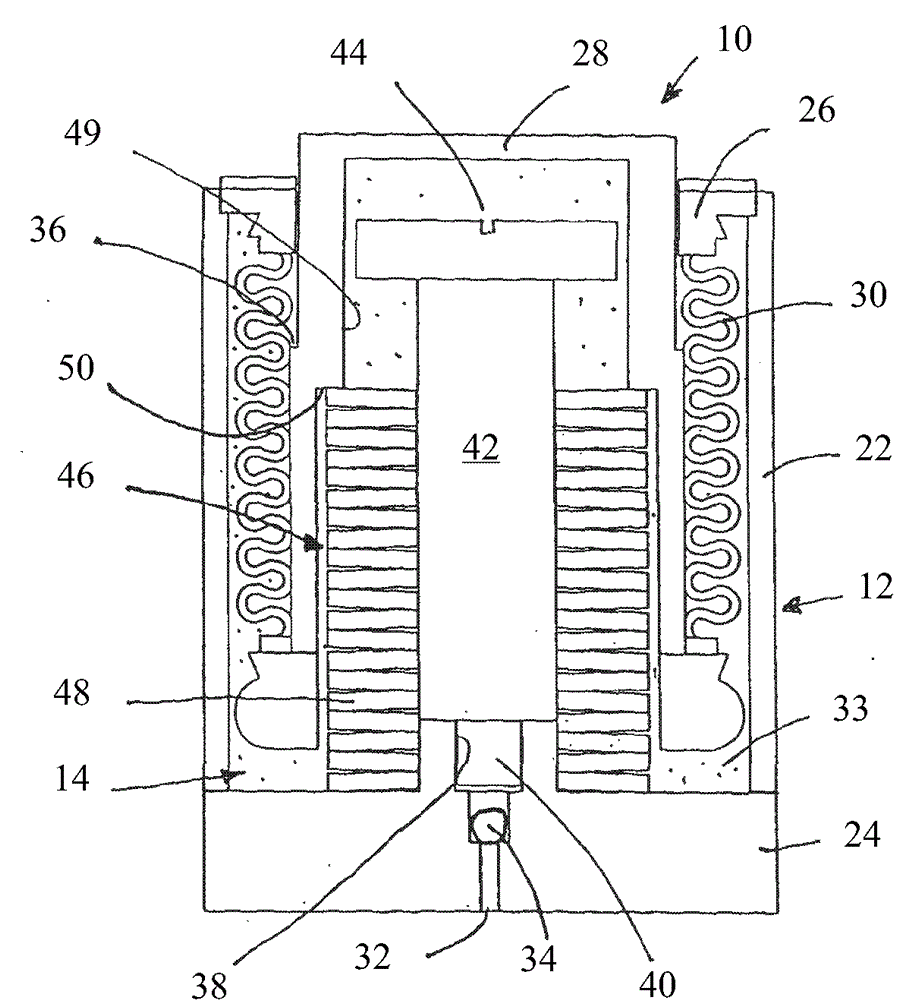

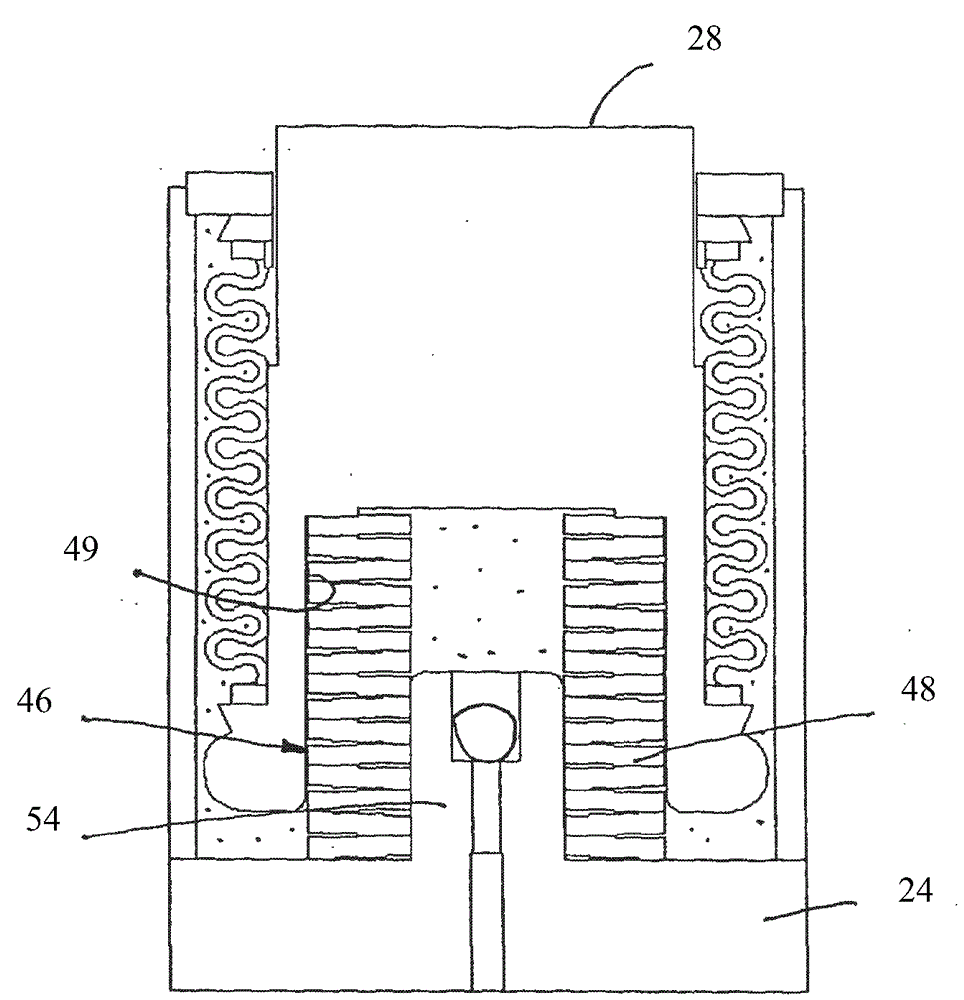

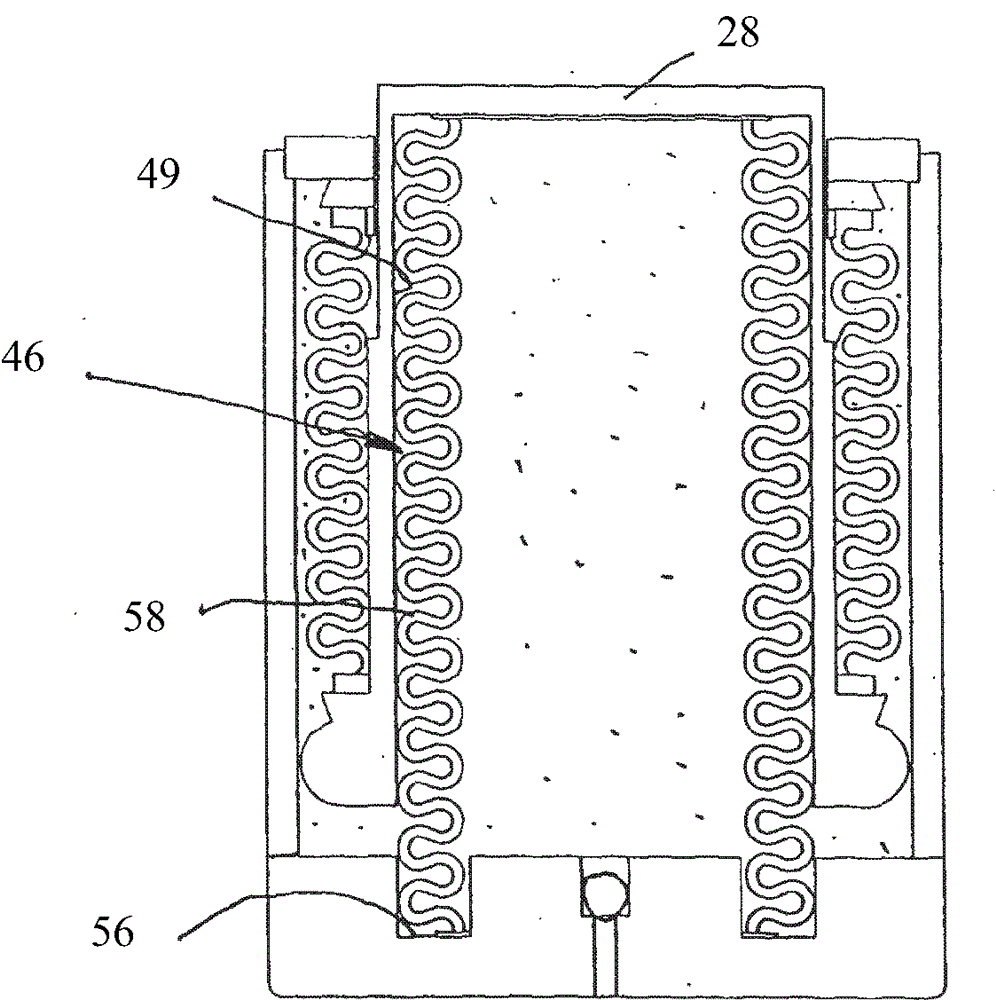

[0024] refer to figure 1 , the exemplary gas spring 10 includes a metal tube 22 onto which a base 24 and a guide sleeve 26 are welded to define the container 12 . A plunger 28 extends through a bore in guide sleeve 26 . Stainless steel bellows 30 is welded at one end to guide sleeve 26 and at the other end to plunger 28 , thereby defining a closure or seal with plunger 28 , metal tube 22 , base 24 and guide sleeve 26 outside bellows 30 and inside container 12 space14.

[0025] The base 24 is provided with an injection hole 32 and a valve 34, whereby the closed space can be filled under pressure with an inert gas 33, such as nitrogen. Gases are represented by dots in the diagram.

[0026] During use, gas pressure acts upwardly on the plunger 28, as shown in the figures.

[0027] The plunger 28 has a circumferential stop 36 for figure 1 The direction shown upwards limits the maximum extension of the plunger.

[0028] The base 24 is provided with a threaded bore 38 that rec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com