Single crystal welding of directionally solidified materials

A technology of directional crystallization and crystallization, which is applied in the field of single crystal welding of directional crystalline materials, and can solve problems such as wrong orientation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

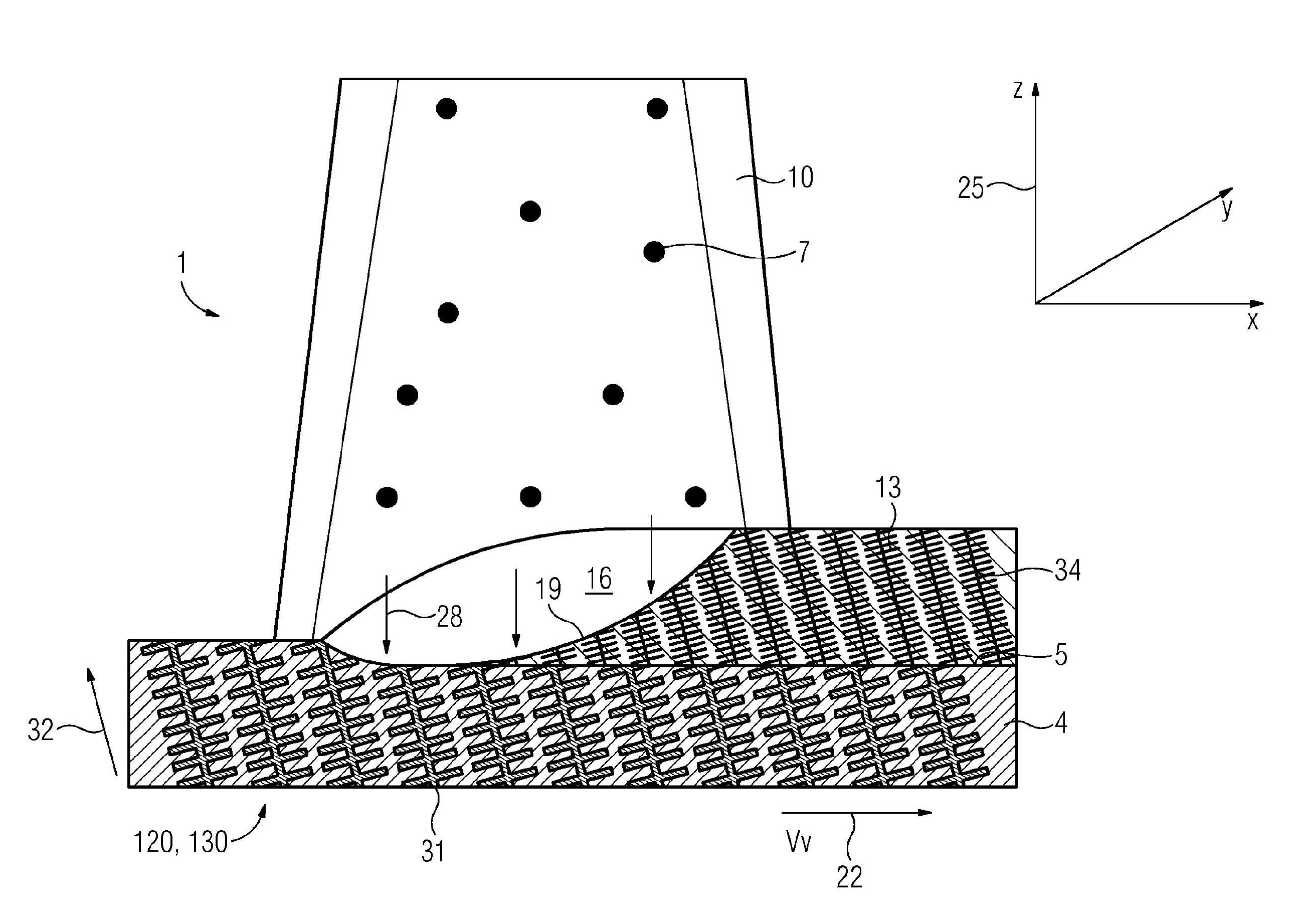

[0014] exist figure 1 The flow of the method is shown schematically with the aid of device 1 .

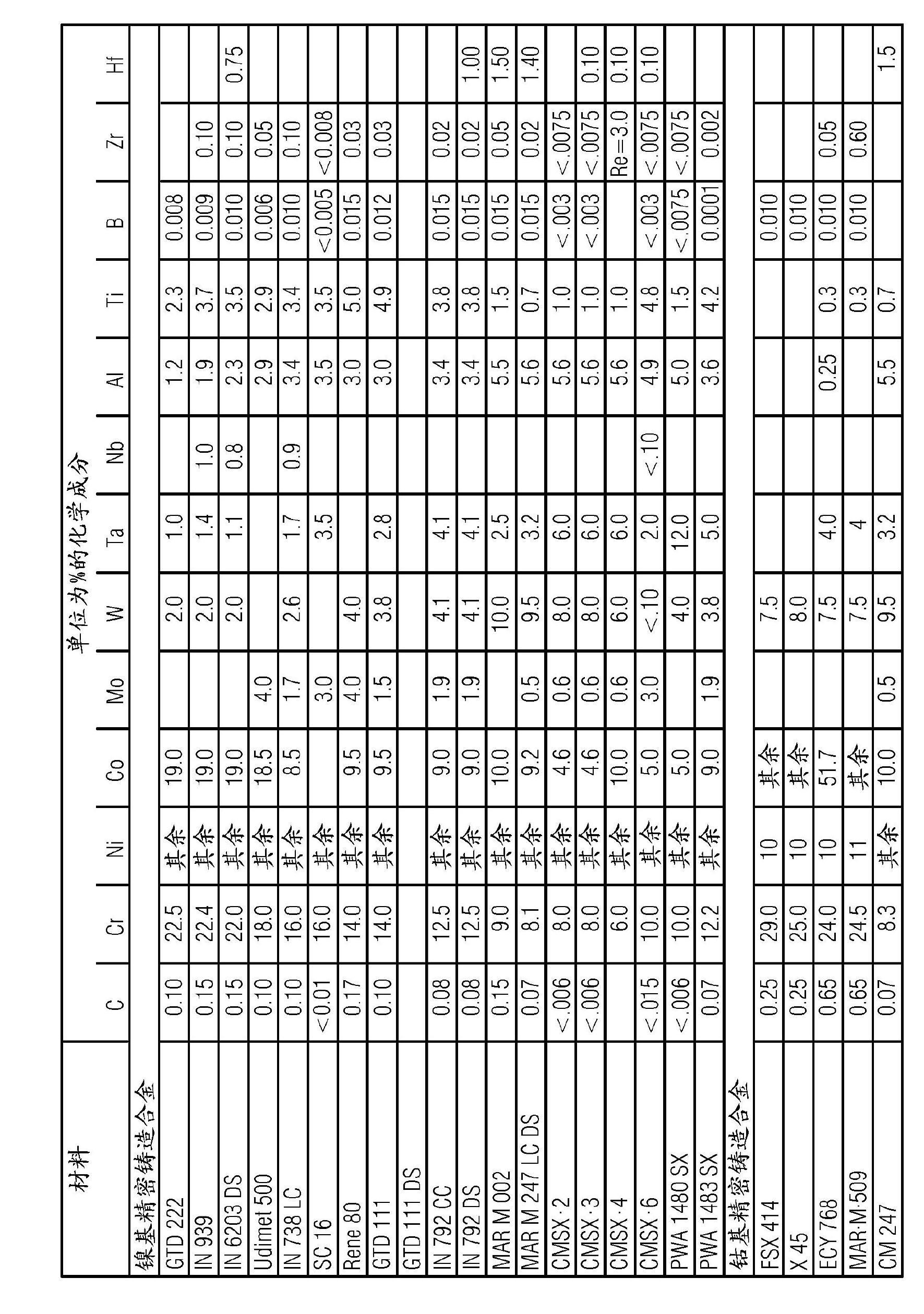

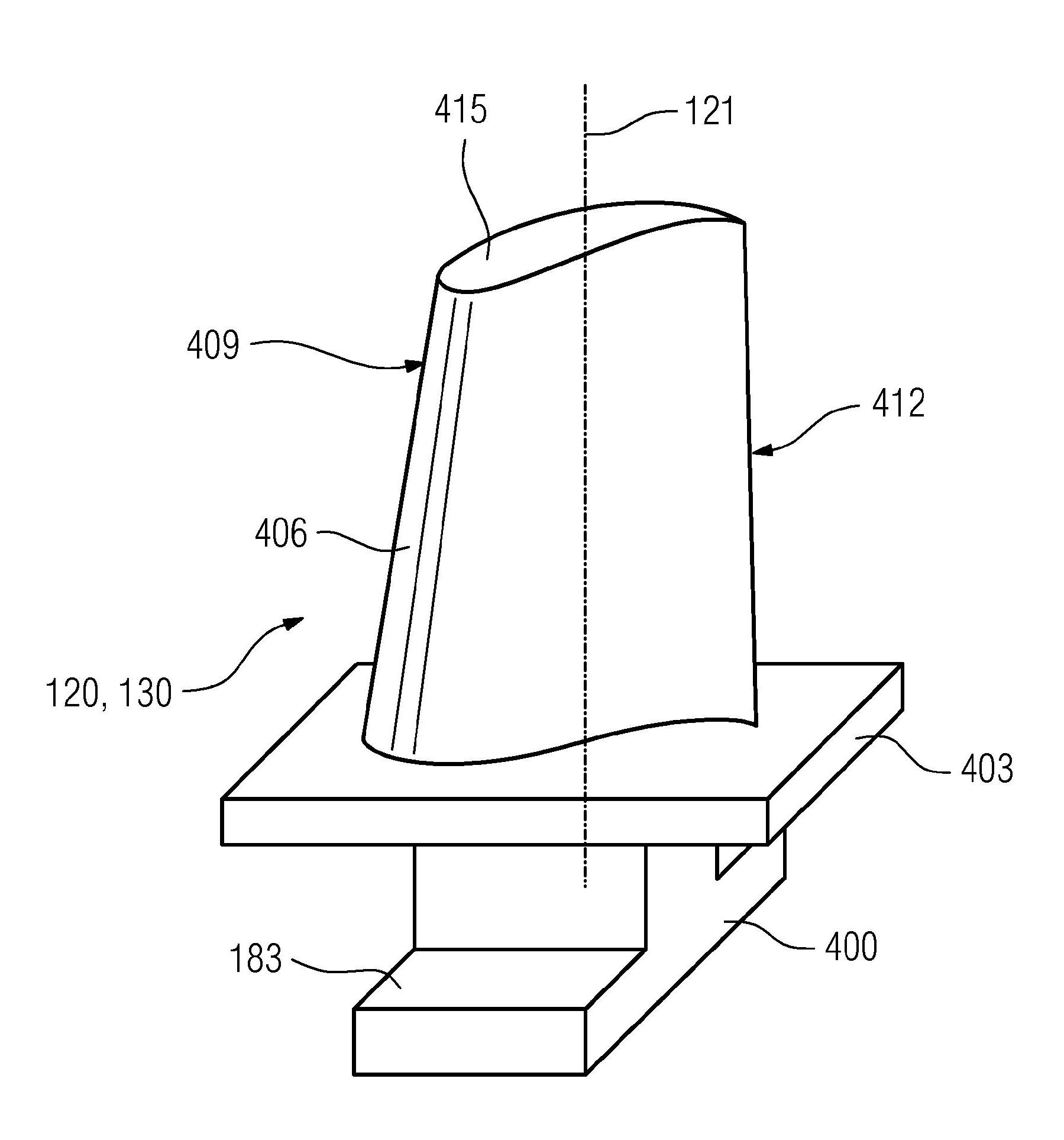

[0015] Components 120, 130 to be repaired have properties made of superalloys, in particular according to Figure 4 A substrate made of a nickel-based superalloy 4 . In particular, the substrate 4 consists entirely of a nickel-based superalloy. The substrate 4 is repaired by applying new material 7 to the surface 5 of the substrate 4 by overlay welding, in particular by means of powder.

[0016] This is achieved by supply material 7 and a welding beam, preferably a laser beam 10 of a laser, which melts at least the supplied material 7 and preferably also partially melts the substrate 4 . Here, powders are preferably used. The diameter of the powder particles 7 is preferably so small that the laser beam completely melts them and achieves a sufficiently high temperature of the particles 7 . During welding, there is a melted region 16 on the substrate 4 , a solidification front 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com