Silico-sodo-calcic glass-ceramic material

A crystalline material and glass technology, which is applied in the field of soda-lime glass crystalline materials, can solve problems such as corrosion of environmental refractory materials, and achieve the effects of improving tempering, increasing mechanical strength, and good resistance to scratch propagation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

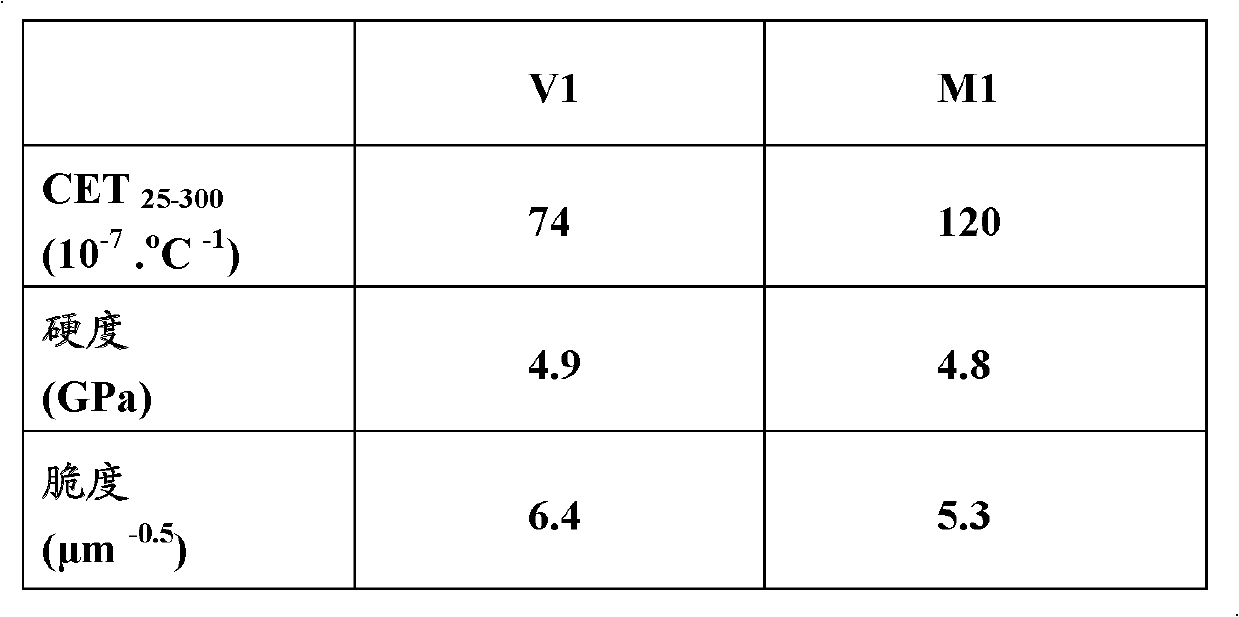

[0064] Composition C1 comprises 80.3% SiO expressed as a percentage of the total weight 2 , 10.3% Na 2 O and 9.4% CaO.

[0065] This composition was melted at a temperature of 1550°C and then poured into a 4cm x 4cm mold with a height of one centimeter. The amorphous glass obtained by gradually cooling composition C1 was then heat-treated by heating (annealing) at 1000° C. for 1 hour, and then gradually cooled to ambient temperature again. For composition C1 material M1 was obtained.

[0066] The coefficient of linear thermal expansion (CET), hardness and brittleness were evaluated for material M1. Hardness (H) and brittleness (B) are determined by Vickers indentation (load: 0.5kg, application time: 25 seconds), while CET is obtained using a dilatometer for a temperature range from 25°C to 300°C (ISO 7991: 1987 standard). These techniques will not be further explained, since they are well known to those skilled in the art of glass materials and glass crystalline materials...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com