Making method of raw tea for flavored tea beverages

A technology for flavored tea and raw materials, which is applied to the preparation of raw material tea for flavored tea beverages and the field of tea processing, can solve the problems of different quality focus, different evaluation methods, unsuitable raw materials for ready-to-drink liquid tea beverages, etc. Processing cost, improving dissolution rate, and prolonging the effect of flavor quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Example 1 A kind of preparation method of raw material tea for flavored tea beverage

[0021] A raw material for flavored tea beverage The fresh leaf raw material used in tea processing is: 50kg of fresh tea leaves mainly selected from varieties.

[0022] (1) The fresh leaves of H209 are selected as raw materials, and the tenderness is 1 bud 4 leaves-1 bud 6 leaves;

[0023] (2) Spread the fresh leaves on the stainless steel wire mesh three-dimensional spreading rack (see figure 1 ), and then place the spreading rack in a temperature-controlled and humidity-controlled spreading room until the moisture content of fresh leaves is about 70%;

[0024] (3) Carry out the greening treatment with the roller-finishing machine (6CST-60 type roller-finishing machine produced by Zhejiang Shangyang Machinery Co., Ltd.) treated in step (2) (the setting temperature is 280°C, single cycle It takes 75s, the amount of leaf throwing is controlled at 70kg / h), and the moisture content o...

Embodiment 2

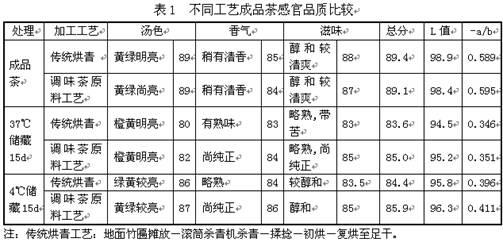

[0034] Take the traditional baked green sample as the control (the traditional baked green adopts the drum fixing method, the moisture content of the green leaves is controlled at about 55-60%, the rolling is treated by cold kneading, and then directly dried twice), and the same extraction process and storage are used. The difference of the two finished teas in terms of processing cost, TP leaching amount and quality stability was compared. The results are shown in Table 1, Table 2, and Table 3. From Table 1, Table 2 and Table 3, it can be seen that ① Compared with the traditional roasted green tea samples, the quality sensory score of the tea soup processed by the flavored tea beverage raw materials obtained by integrated hot kneading, cell crushing and other processes decreases under high temperature conditions. A decrease of 29.3%. ②In terms of processing cost, compared with traditional roasted green tea leaves, the processing cost of special raw material tea for flavored ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com