Swertia mileensis dispersible tablet and preparation method thereof

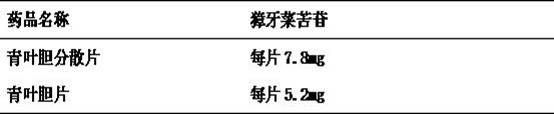

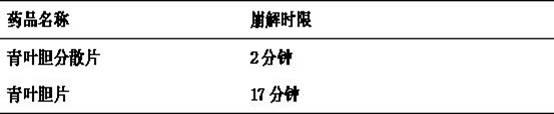

A technology of green leaf gallbladder and dispersible tablets, which can be applied to medical preparations without active ingredients, medical preparations containing active ingredients, and pharmaceutical formulas, etc., and can solve the problems of incomplete extraction of active ingredients, delayed disintegration, and low efficacy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Take 1570g of Foliage gallbladder, crush it into a 60-mesh coarse powder, and use carbon dioxide supercritical extraction method to extract, the extraction pressure is 20Mpa, the extraction temperature is 20°C, the separator pressure is 10Mpa, the separator temperature is 40°C, the separation time is 2 hours, and the flow of carbon dioxide per hour 20L to obtain the extract; take the extract and dry it under reduced pressure at 60°C to obtain a dry paste; add 80g of calcium sulfate to the dry paste, and use a high-energy nano-impact mill to pulverize it into a mixed dry paste powder with a particle size of 200-300nm; take the mixed dry paste powder , microcrystalline cellulose 35g, crospovidone 35g, croscarmellose sodium 35g, hypromellose 25g, micropowder silica gel 15g, sodium chloride 5g, mannitol 4g, lactose 4g, mix well, Wet granulate with 50% ethanol, dry at 60°C, add 7g of sodium carboxymethyl starch, 1g of magnesium stearate, granulate, press into 1000 pieces, and...

specific Embodiment 2

[0023] Take 1570g of Foliage gallbladder, crush it into a 60-mesh coarse powder, and use carbon dioxide supercritical extraction method to extract, the extraction pressure is 40Mpa, the extraction temperature is 40°C, the separator pressure is 20Mpa, the separator temperature is 60°C, the separation time is 4 hours, and the flow rate of carbon dioxide per hour 40L to obtain the extract; take the extract and dry it under reduced pressure at 80°C to obtain a dry paste; add 120g of calcium sulfate to the dry paste, and use a high-energy nano-impact mill to pulverize it into a mixed dry paste powder with a particle size of 200-300nm; take the mixed dry paste powder , microcrystalline cellulose 45g, crospovidone 45g, croscarmellose sodium 45g, hypromellose 35g, micropowder silica gel 25g, sodium chloride 15g, mannitol 6g, lactose 6g, mix well, Wet granulate with 70% ethanol, dry at 80°C, add 9g of sodium carboxymethyl starch, 3g of magnesium stearate, granulate, press into 1000 piec...

Embodiment 3

[0025] Take 1570g of Foliage gallbladder, crush it into 60 mesh coarse powder, and use carbon dioxide supercritical extraction method to extract, the extraction pressure is 30Mpa, the extraction temperature is 30°C, the separator pressure is 15Mpa, the separator temperature is 50°C, the separation time is 3 hours, and the flow rate of carbon dioxide per hour 30L to obtain the extract; take the extract and dry it under reduced pressure at 70°C to obtain a dry paste; add 100g of calcium sulfate to the dry paste, and use a high-energy nano-impact mill to pulverize it into a mixed dry paste powder with a particle size of 200-300nm; take the mixed dry paste powder , microcrystalline cellulose 40g, crospovidone 40g, croscarmellose sodium 40g, hypromellose 30g, micropowder silica gel 20g, sodium chloride 20g, mannitol 5g, lactose 5g, mix well, Wet granulate with 60% ethanol, dry at 70°C, add 8g of sodium carboxymethyl starch, 2g of magnesium stearate, granulate, press into 1000 pieces...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com