A kind of Xiaoer Qingyan granule and its preparation method

A granule, pediatric technology, applied in pharmaceutical formulations, medical preparations containing active ingredients, plant raw materials, etc., can solve the problems of active ingredient destruction, insufficiency, loss, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

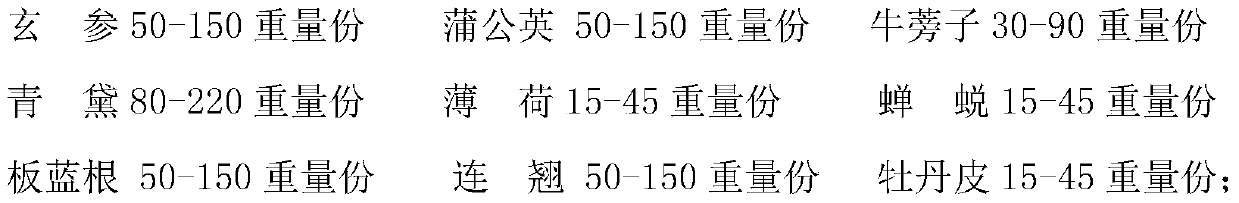

Embodiment 1

[0074]

[0075] Take 1 / 3 of Radix Radix and 1 / 3 of Forsythia, wash and dry them separately, and use a high-speed pulverizer to crush them through an 80-mesh sieve to get fine powder; wash and dry Scrophulariaceae and cicada slough respectively, and crush them with high speed Machine crushed through 80-mesh sieve to get fine powder; wash the remaining 2 / 3 of Radix isatidis, decoct twice with 8 times the amount of water, the first time for 2 hours, the second time for 1.5 hours, combine the two decoctions, Filter, concentrate the filtrate to 80°C to measure the relative density of 1.15-1.18, add ethanol to make the alcohol content reach 65%, let stand, take the supernatant to recover ethanol, and concentrate to 80°C to measure the relative density of 1.25-1.30. Cream A; wash the remaining 2 / 3 of the forsythia with water, add 8 times the amount of water to decoct twice, the first time for 2 hours, the second time for 1.5 hours, combine the two decoctions, filter, and centrifuge...

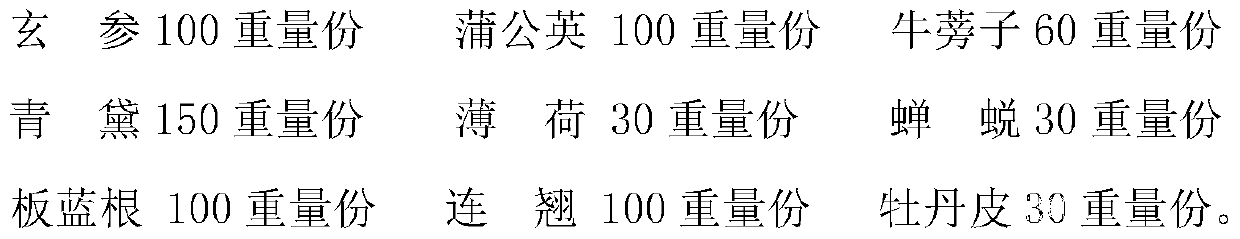

Embodiment 2

[0077]

[0078] Take 1 / 3 of Radix Radix and 1 / 3 of Forsythia, wash and dry them separately, and use a high-speed pulverizer to crush them through an 80-mesh sieve to get fine powder; wash and dry Scrophulariaceae and cicada slough respectively, and crush them with high speed Machine crushed through 80-mesh sieve to get fine powder; wash the remaining 2 / 3 of Radix isatidis, decoct twice with 8 times the amount of water, the first time for 2 hours, the second time for 1.5 hours, combine the two decoctions, Filter, concentrate the filtrate to 80°C to measure the relative density of 1.15-1.18, add ethanol to make the alcohol content reach 65%, let stand, take the supernatant to recover ethanol, and concentrate to 80°C to measure the relative density of 1.25-1.30. Cream A; wash the remaining 2 / 3 of the forsythia with water, add 8 times the amount of water to decoct twice, the first time for 2 hours, the second time for 1.5 hours, combine the two decoctions, filter, and centrifuge...

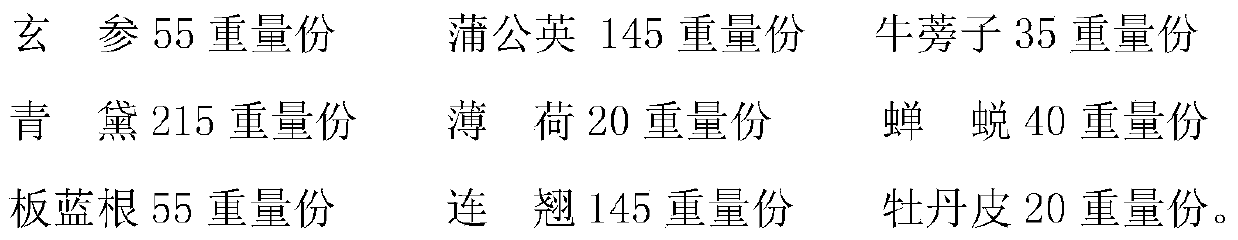

Embodiment 3

[0080]

[0081] Take 1 / 3 of Radix Radix and 1 / 3 of Forsythia, wash and dry them separately, and use a high-speed pulverizer to crush them through an 80-mesh sieve to get fine powder; wash and dry Scrophulariaceae and cicada slough respectively, and crush them with high speed Machine crushed through 80-mesh sieve to get fine powder; wash the remaining 2 / 3 of Radix isatidis, decoct twice with 8 times the amount of water, the first time for 2 hours, the second time for 1.5 hours, combine the two decoctions, Filter, concentrate the filtrate to 80°C to measure the relative density of 1.15-1.18, add ethanol to make the alcohol content reach 65%, let stand, take the supernatant to recover ethanol, and concentrate to 80°C to measure the relative density of 1.25-1.30. Cream A; wash the remaining 2 / 3 of the forsythia with water, add 8 times the amount of water to decoct twice, the first time for 2 hours, the second time for 1.5 hours, combine the two decoctions, filter, and centrifuge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com