Method for casting small-specification copper rod based on upward casting

A technology of small size, copper rod, applied in the field of casting, can solve the problems of low efficiency, high cost, long production time, etc., and achieve the effect of improving economic benefits, saving costs and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

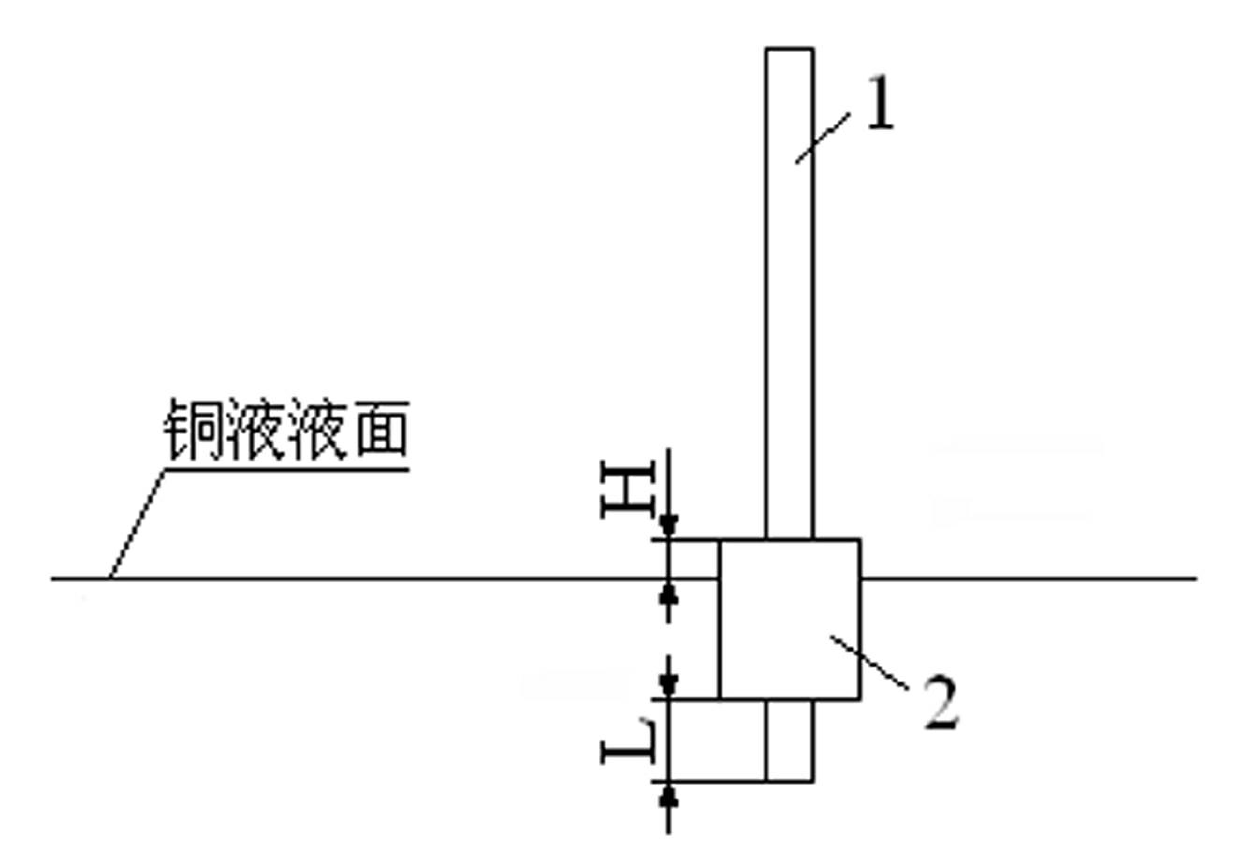

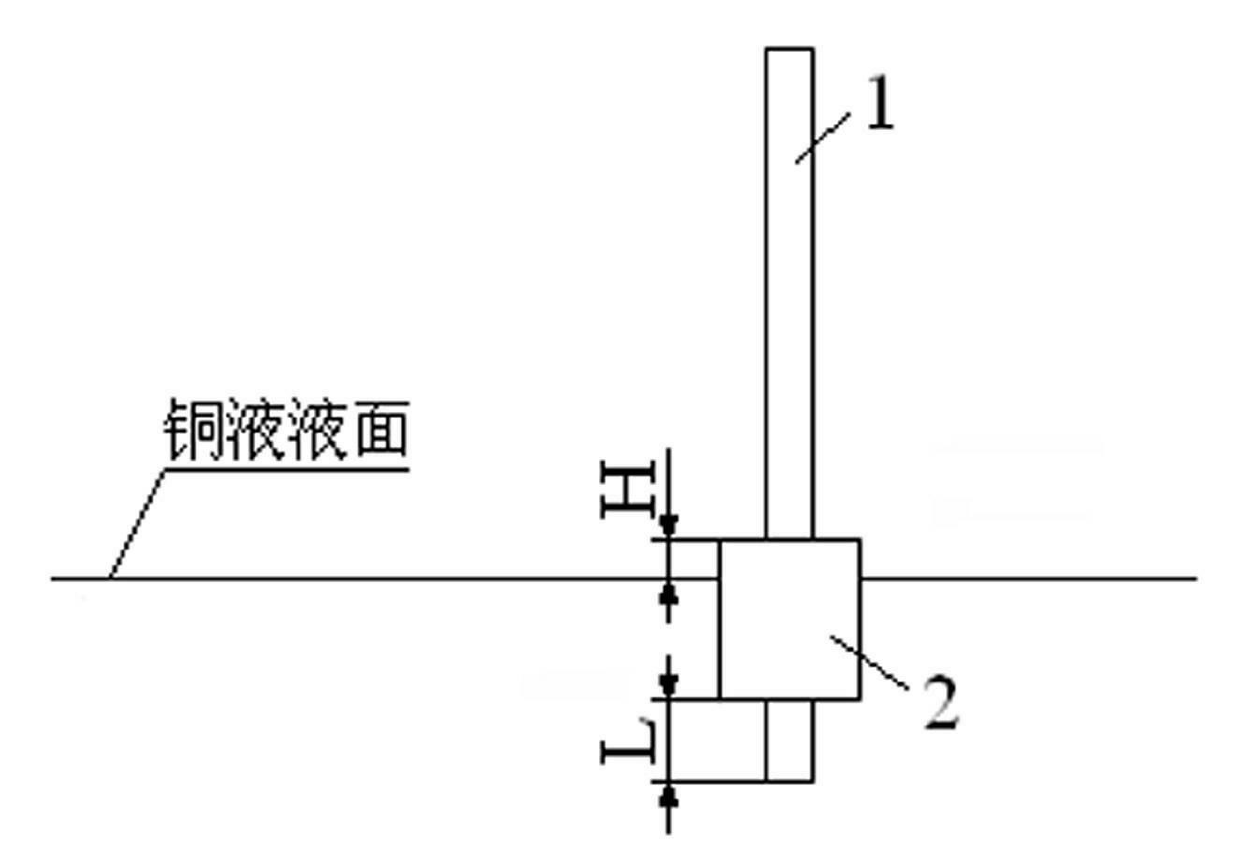

Embodiment 1

[0023] First adjust the temperature of the holding furnace body of the up-drawing furnace to 1118°C, and then raise the temperature of the holding furnace body of the up-drawing furnace to 1120°C at a rate of 2°C per 30 minutes; 2 racks of the crystallizer to the upper lead furnace body and baked for 30 minutes; the extruded copper lead rod 1 with a diameter of 5mm is inserted into the crystallizer 2 from the upper end of the crystallizer 2 baked in step 1, so that the copper lead rod 1 The protruding length from the lower port of crystallizer 2 is 40mm, and then insert mold 2 into the copper liquid, so that the tail end of the graphite protection sleeve in the crystallizer 2 is above the liquid surface of the copper liquid, and the tail end of the graphite protection sleeve is in contact with the copper liquid The distance between the surfaces is 1 / 3 of the total height of the crystallizer 2. Fix the crystallizer 2, clamp the copper lead rod by the existing method, and start t...

Embodiment 2

[0026] First adjust the temperature of the holding furnace body of the upper drawing furnace to 1116°C, then raise the temperature of the holding furnace body of the upper drawing furnace to 1120°C at a rate of 1°C per 30 minutes; 2 frames of the required crystallizers are baked for 25 minutes on the upper lead furnace body; the extruded copper lead rod 1 with a diameter of 4mm is inserted into the crystallizer 2 from the upper end of the baked crystallizer 2, so that the copper lead rod 1. The protruding length from the lower port of the crystallizer 2 is 30mm, and then insert the crystallizer 2 into the copper liquid, so that the tail end of the graphite protection sleeve in the crystallizer 2 is above the liquid surface of the copper liquid, and the tail end of the graphite protection sleeve is in contact with the copper liquid The distance between the surfaces is 1 / 3 of the total height of the crystallizer 2. Fix the crystallizer 2. Use the existing method to clamp the copp...

Embodiment 3

[0029]First adjust the temperature of the holding furnace body of the upper drawing furnace to 1117°C, and then raise the temperature of the holding furnace body of the upper drawing furnace to 1120°C at a rate of 1.5°C per 30 minutes; 2 racks of required crystallizers are baked for 28 minutes on the upper lead furnace body; the extruded copper lead rod 1 with a diameter of 4.5mm is inserted into the crystallizer 2 from the upper mouth of the baked crystallizer 2, so that the copper lead rod 1. The protruding length from the lower port of the crystallizer 2 is 35mm, and then insert the crystallizer 2 into the copper liquid, so that the tail end of the graphite protection sleeve in the crystallizer 2 is above the liquid surface of the copper liquid, and the tail end of the graphite protection sleeve is in contact with the copper liquid The distance between the surfaces is 1 / 3 of the total height of the crystallizer 2. Fix the crystallizer 2, clamp the copper lead rod by the exis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com