Temperature control system for crystal phosphoric acid production

A temperature control system, phosphoric acid technology, applied in the direction of phosphoric acid, phosphorus oxyacid, etc., to achieve the effect of simple operation, ensure operation reliability and safety, and fast temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

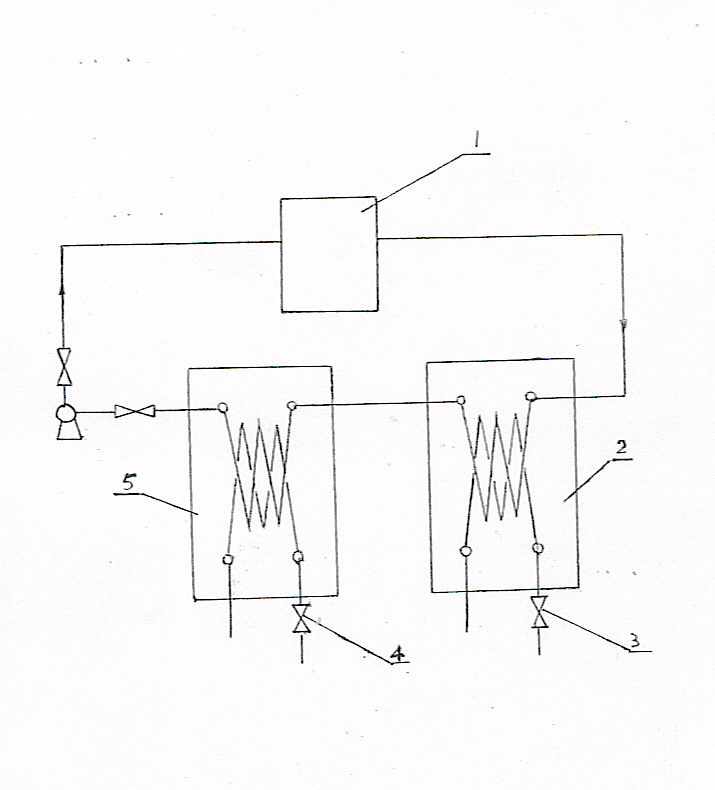

[0013] attached figure 1 The structure of the present invention is illustrated. A crystalline phosphoric acid production temperature control system of a certain phosphorus industry limited liability company includes a crystallizer 1 and a plate heat exchanger. It is characterized in that there are two plate heat exchangers, one for refrigeration Heat exchanger 5 and the other heat exchanger 2 are heat exchangers. The inlets of the two plate heat exchangers are all equipped with valve controls, and the crystallizer 1 and the two plate heat exchangers are connected in series by pipes.

[0014] The cooling heat exchanger 5 has a circulating cold medium as its working medium, and the heating heat exchanger 2 has a circulating heat medium as its working medium. The process circulating water pipe flowing through the crystallizer 1 connects the crystallizer 1 and two plate heat exchangers in series. The process circulating water in the process circulating water pipe flows through two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com