Treatment method for recycling waste sodium chlorate sewage

A waste sodium hypochlorite and treatment method technology, which is applied in the field of waste sodium hypochlorite sewage treatment, can solve the problems of expensive chemicals, resource waste, environmental pollution, etc., achieve low water treatment and waste water reuse costs, realize recycling, and simple process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

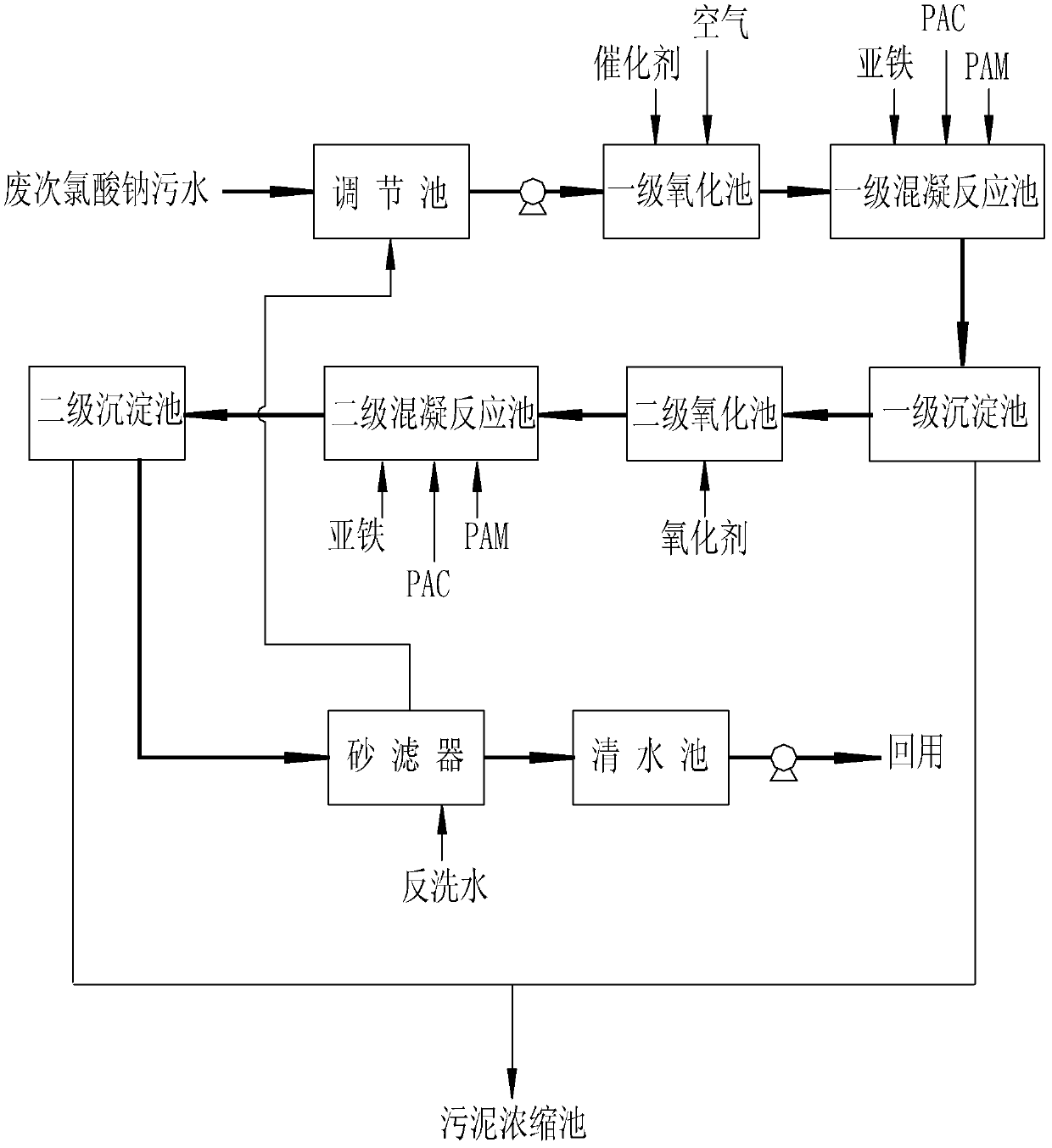

Method used

Image

Examples

Embodiment Construction

[0019] The following describes the detailed process of the present invention through the examples, and the examples are provided for the convenience of understanding, and are by no means limiting the present invention.

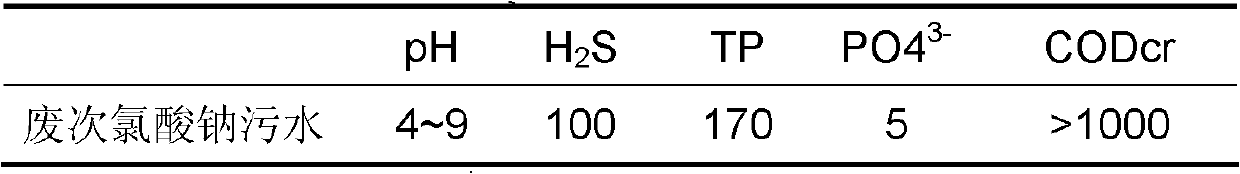

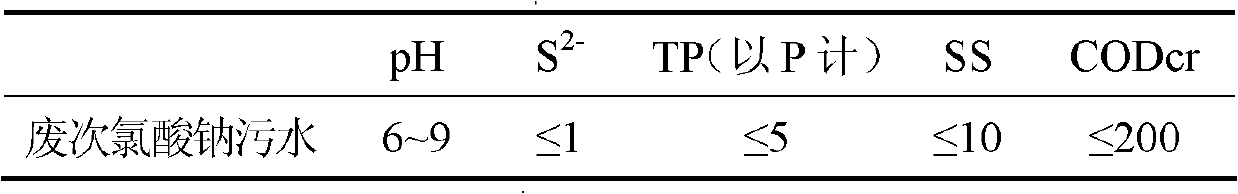

[0020] Introduction to research materials: The average daily discharge of sodium hypochlorite sewage discharged from an established chemical plant is 4,800 tons, and the influent water quality indicators are shown in Table 1. For the specific influent water quality, it can be found that in TP (total phosphorus), the content of orthophosphate is very low, and the main component of TP (total phosphorus) is phosphite. The COD (chemical oxygen demand) content is high because the sewage contains sulfide and acetylene gas. With the process of removing sulfide and aeration to remove acetylene gas, the COD content will decrease rapidly.

[0021] Table 1 Water quality of waste sodium hypochlorite sewage Unit: mg / L

[0022]

[0023] (1) Storage and promotion of inco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com