Silicon slurry and preparation method thereof

A technology of silicon slurry and micro-silica fume, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of gelation of silicon slurry, unsatisfactory results, and inability to recover gels, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

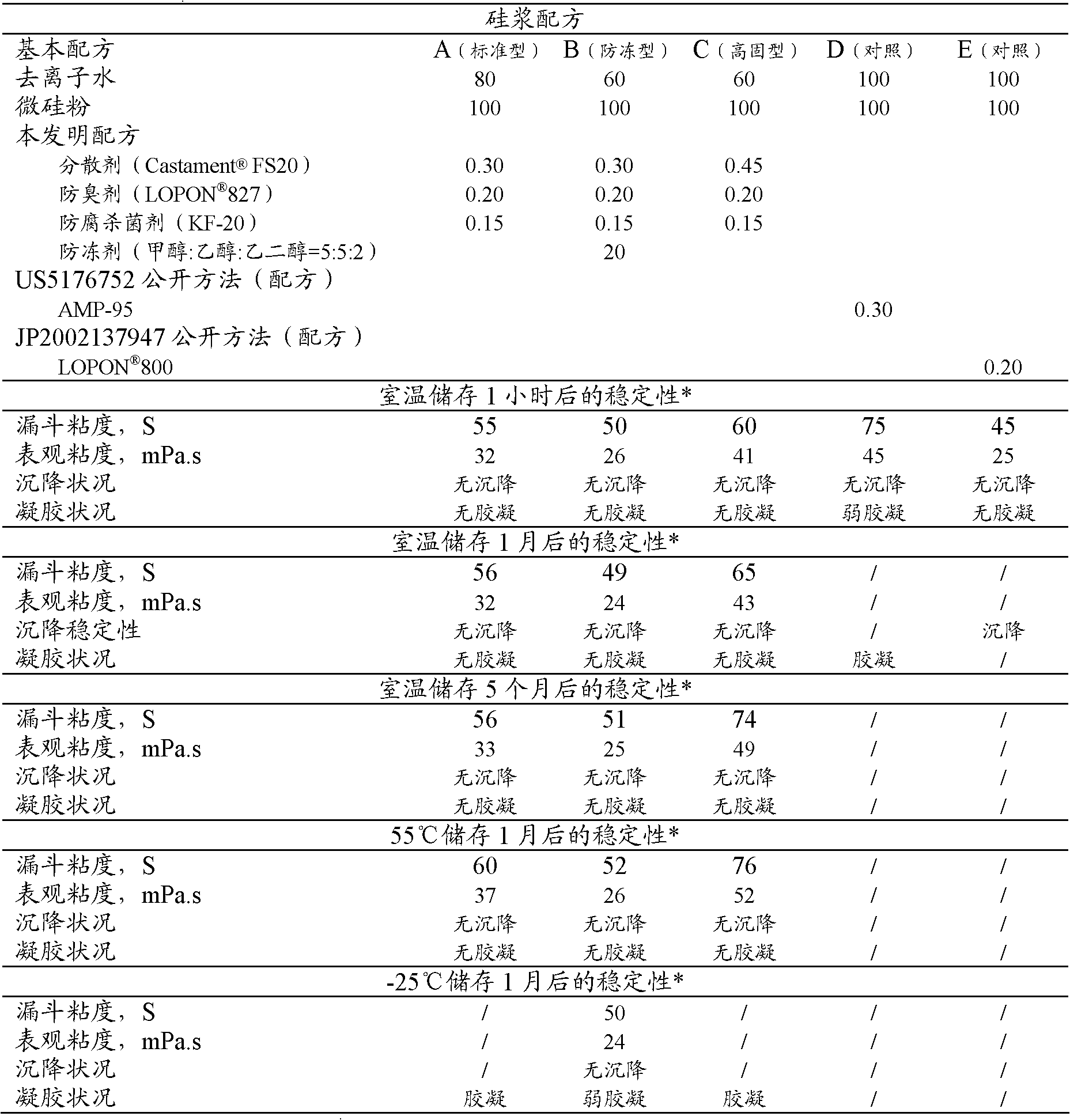

Embodiment 1

[0036] Put the slurry cup filled with deionized water on a high-speed stirrer, slowly add microsilica powder at a speed of 4000rpm, and stir at a speed of 12000rpm for several minutes to obtain a viscous slurry. Auxiliary composition, 1000rpm low-speed stirring to get the silicon slurry. According to the formula in Table 1, it can be prepared that the solid content is 55.6% (A slurry), 62.5% (C slurry) and the silicon slurry with a solid content of 55.6% and antifreeze (B slurry). From the performance evaluation results shown in Table 1 below, it can be seen that the silicon paste prepared by the present invention has the characteristics of long-term storage stability. Neither the silicon paste (D paste) prepared by the method disclosed in US5176752 patent nor the silicon paste (E paste) prepared by the method disclosed in JP2002137947 patent can meet the requirements of long-term storage stability.

[0037] Table 1 Silicon paste prepared according to each formula and its per...

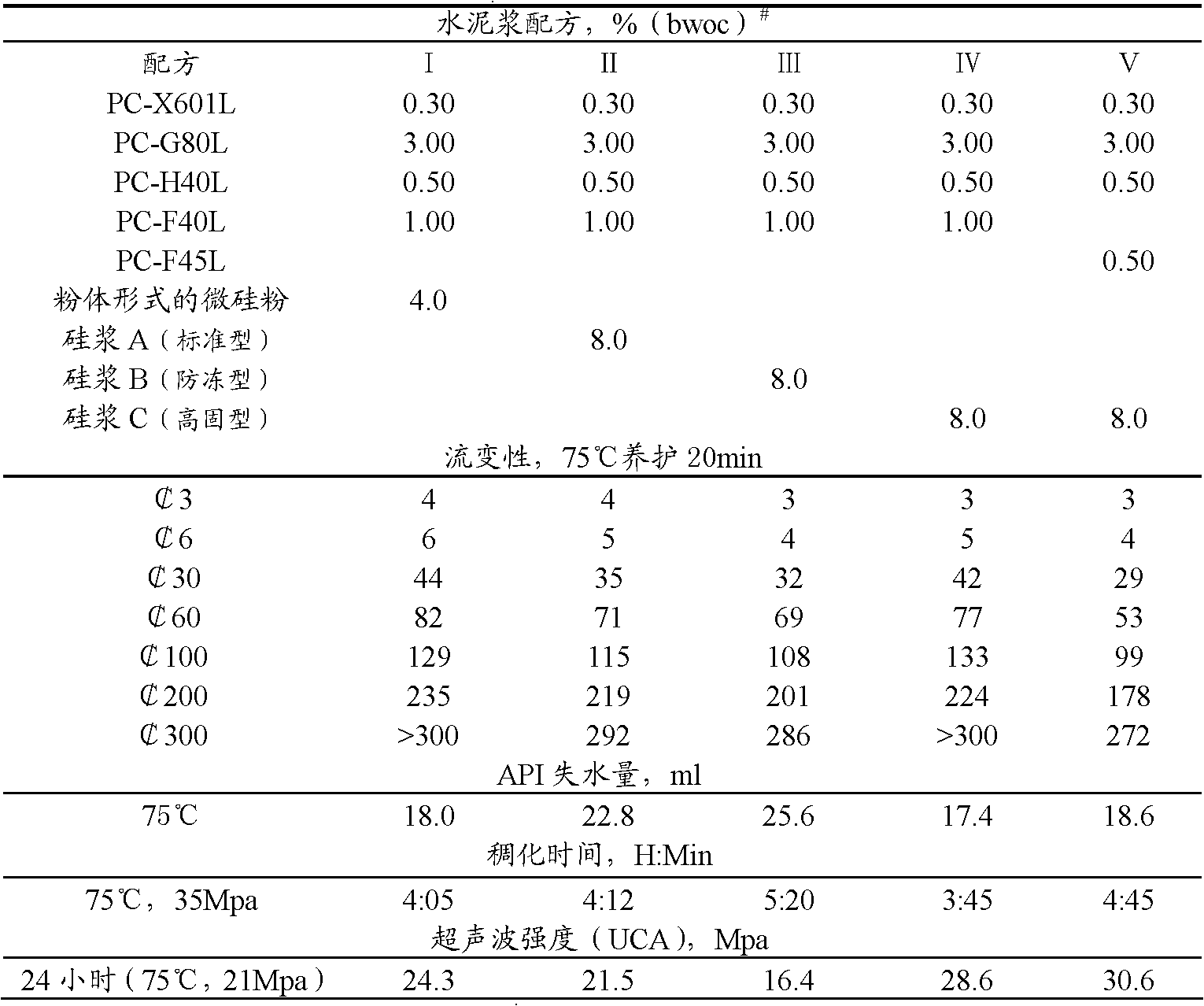

Embodiment 2

[0041] In the cementing slurry, the performance difference between microsilica powder in the form of powder and silicon slurry in the form of its aqueous solution was measured, and the comparison results are shown in Table 2. As can be seen from Table 2, there is no significant difference between the silicon slurry prepared by the present invention and the microsilica fume in powder form on the cement slurry performance, and for well cementing construction, it is not only convenient to use silicon slurry, Moreover, it is beneficial to the personal protection of the user because no dust phenomenon will be generated. It can also be seen from Table 2 that both silicon slurry or microsilica fume thicken the cement slurry, and when the polycarboxylic acid dispersant PC-F45L is used, the rheological properties of the cement slurry are better than those of the sulfonated aldehyde-ketone condensation dispersant PC-F40L .

[0042] Table 2 1.95S.G cement slurry formula and performance ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com