Processing method of solid glass cleaner

A processing method and cleaning agent technology, which are used in the cleaning of the front windshield of automobiles, the production of a solid glass cleaner, and the field of glass cleaning, which can solve the problem of troublesome operation, surrounding pollution, and being susceptible to sediment and dust. , oil pollution and rain and fog

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The invention relates to a processing method of a solid glass cleaner, which is characterized in that:

[0015] ①According to the weight ratio, take 45-55 parts of sodium lauryl sulfate powder, 30-35 parts of sodium bicarbonate powder, 9-13 parts of citric acid granules, 4-6 parts of L-HPC powder, and 0.1-0.3 parts of fen basket Copies

[0016] ② The ambient temperature during processing is 18-21℃, and the humidity is 20-25%;

[0017] ③. Processing process:

[0018] The first step is to take citric acid particles and process them into powder with a pulverizer;

[0019] The second step is to weigh all the raw materials according to the proportion, put them into the mixer and mix them uniformly to obtain the original powder, and then seal and store;

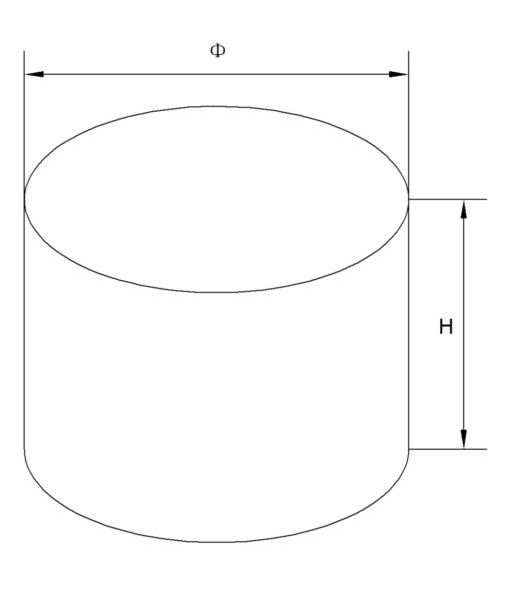

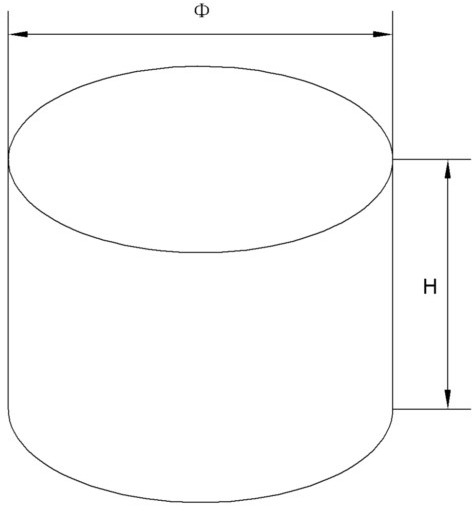

[0020] In the third step, the uniformly stirred raw powder is compressed into round tablets by a tablet press, and the formed tablets are sealed and packaged.

[0021] Sodium lauryl sulfate in the ingredients plays the main role of cle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com