Method for recovering scandium from zirconium oxychloride acid pickle, and extracting agent for method

A technology of zirconium oxychloride and extractant, which is applied in the field of rare earth recovery, can solve problems such as the inability to recover scandium, and achieve the effect of large processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

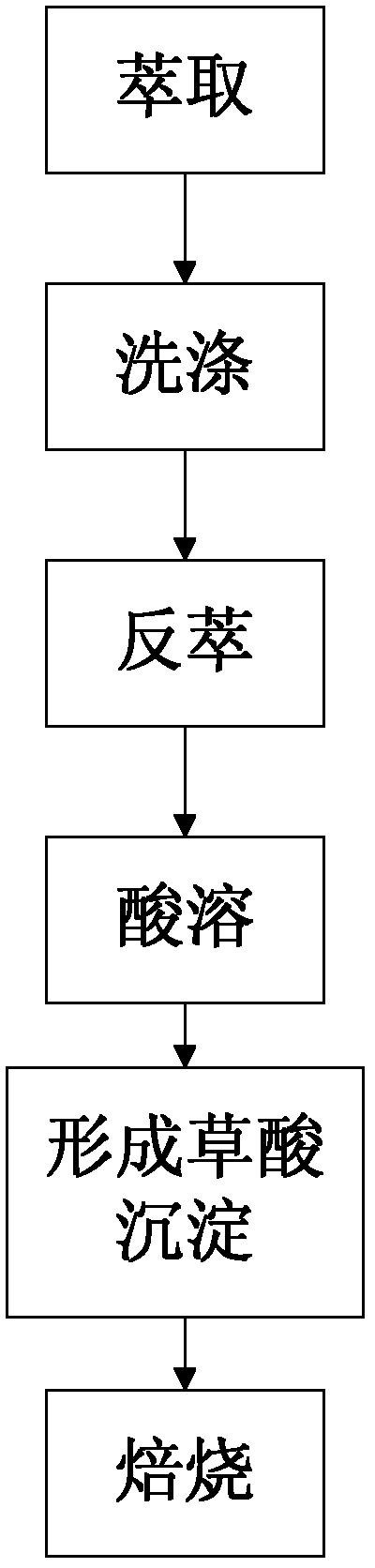

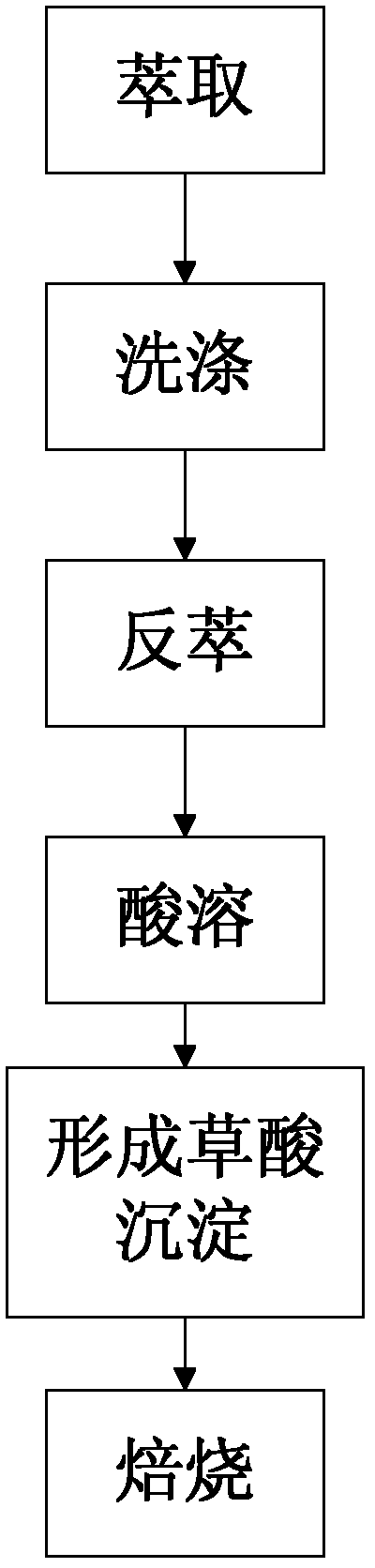

Method used

Image

Examples

Embodiment

[0031] All materials and instruments used in the following examples are commercially available.

[0032] Extraction rate calculation formula: extraction rate = (scandium content in waste acid solution - scandium content in aqueous phase after extraction) / scandium content in waste acid solution * 100%;

[0033]Scandium, titanium, zirconium, and rare earth elements in the solution are determined by conventional titration colorimetry and ICP instrument method. Sc in roasted product 2 o 3 The content was determined by conventional titration.

example 1

[0035] Extraction: Take 100ml of waste acid solution in the production process of zirconium oxychloride, acidity 4N, Sc0.4g / L, Ti16g / L, Zr21g / L, Th0.6g / L, rare earth 4.5g / L, put it into 1L liquid separation In the funnel, add 500ml extractant, the ratio O / A is 5 / 1. The extractant is composed of 79% by volume of P350 and 21% by volume of P507, adding kerosene with 70% by volume of the extractant as a diluent, shaking and extracting for 10 minutes, static layering at room temperature, and Sc0.007g / L in the equilibrium water phase, Ti13.0g / L, Zr14.99g / L, Th0.47g / L, rare earth 4.46g / L,. The extraction rate of scandium in this step is 98.2%. The titanium extraction rate is 18.7%. The extraction rate of zirconium is 28.6%. The extraction rate of thorium is 21.6%, and the extraction rate of rare earth is 0.8%

[0036] Washing: use 500ml of 4N HCl+1NH2O2, the ratio O / A is 1 / 1, wash the organic phase 3 times to obtain the water wash phase. The loss rate of scandium after water was...

example 2

[0041] Extraction: Take 150ml of waste acid solution in the production process of zirconium oxychloride, acidity 7N, Sc0.25g / L, Ti12.8g / L, Zr16.8g / L, Th0.48g / L, rare earth 3.5g / L, put into In a 1L separatory funnel, add 150ml of extractant, and the O / A ratio is 1 / 1. Add an extractant composed of 99% by volume of P350 and 1% by volume of P507, take 50% by volume of kerosene as a diluent, shake and extract at 25°C for 10 minutes, statically separate layers, and balance the Sc0. 025g / L, Ti11.93g / L, Zr14.1g / L, Th0.42g / L, rare earth 3.49g / L,. The extraction rate of scandium in this step is 90%. The titanium extraction rate is 6.8%. The extraction rate of zirconium is 16.1%. The extraction rate of thorium is 12.5%, and the extraction rate of rare earth is 0.2%

[0042] Washing: the organic phase was washed 3 times with 300 ml of 7N HCL to obtain a water wash phase. The loss rate of scandium after water washing is 6.5%, and some impurities such as titanium, thorium, zirconium an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com