Large-sized closed roof formed by light steel truss arch for building

A lightweight steel and roof technology, applied in the direction of roofs, buildings, building components, etc., can solve the problem that the roof of large buildings cannot be closed, and achieve the effect of reducing the self-weight of the roof, less interdependence, and less structural

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

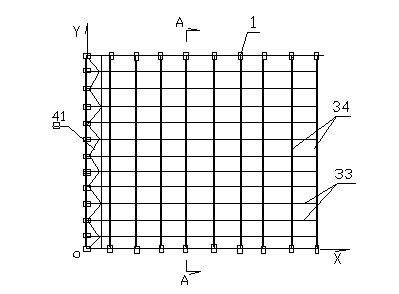

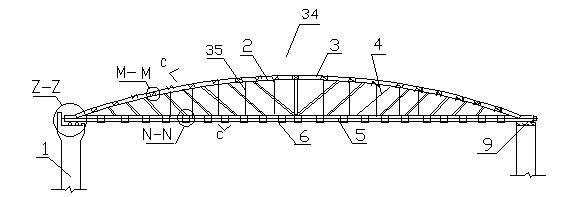

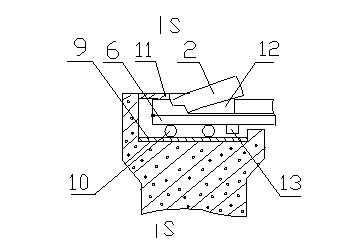

[0034] Example 1, in Figure 1-Figure 9 middle, figure 1 It is a hangar with a rectangular roof, the length of the hall (X direction) is 270 meters, and the width (Y direction) is 240 meters. There are concrete columns 1 on the three surrounding sides, and there are no concrete columns in the middle and right end. There are two rows in the X direction, 31 concrete columns in each row, a total of 30 bays, the first section of the concrete column is 1000×700, and the two sides of the end column and the top section of the rolling bearing are made into short corbels, including corbels 1. The section length of the top of the column is 1200 mm, and the spacing between each span is 9 meters, a total of 270 meters; there is a row in the Y direction, and there are 39 concrete columns in the upper span of the row, with a total of 40 spacings, and the section of the concrete columns is 500×800. Each space is 6 meters, a total of 240 meters; arch trusses 34 are arranged on the two concre...

Embodiment 2

[0035] Example 2, in Figure 10-Figure 15 middle, Figure 10 It is a gymnasium with a circular roof. The diameter of the roof is 240 meters. There are concrete columns 1 around and no concrete columns in the middle. The entire roof is provided with 24 rows of arch trusses 34 (can also be designed as 22 or 18 rows). One end of the lower beam is movable on the concrete column 1, and the other end is fixed on the concrete column. Except that the central structure is different from Embodiment 1, other structures are the same as Embodiment 1. The structure of the upper beam and the lower beam at the center of the roof is: a connecting steel disc is arranged in the middle of the roof, and the connecting steel disc includes an upper round steel disc 22 and a lower round steel disc 23, and tenons are arranged around the upper round steel disc 22 Seat 24, the tenon seat and the upper round steel plate are integral, also can be combined with last round steel plate as a whole, welded i...

Embodiment 3

[0036] Example 3, in Figure 16 and Figure 18 Among them, embodiment 3 is based on embodiment 2. In order to improve the lighting degree, indoor air flow and appearance aesthetics of the circular roof, the circular roof is provided with skylights capable of lighting and mechanical ventilation. The arc slope is higher than the circular roof surface. The skylight roof is composed of glass lighting panels 37 and triangular frames 28. The glass lighting panels are in the shape of a continuous inverted V-shaped folded surface. The triangular frame is located between the glass lighting panels and the circular roof. An exhaust fan 27 is arranged in the skylight, and the glass daylighting panel is generally made of double-layer astigmatism glass (such as embossed glass, frosted glass), and an annular drainage groove 40 is arranged around the circular roof, and the drainage groove is supported on On the ring-shaped concrete beam 39, the edge portion of the roof is formed by inclined ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com