Oil shale mining method and device

A mining method and oil shale technology are applied in the field of underground direct gasification and dry distillation of coal and oil shale to produce oil and gas, and in-situ co-gasification and dry distillation of coal and oil shale to produce oil and gas, which can solve the work of oil shale mining. It can improve the energy utilization rate, shorten the oil production process, and avoid the surface collapse.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Considering the problems existing in the related art, the present invention provides an oil shale mining method. Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. It should be understood that the embodiments described below by referring to the figures are exemplary only for explaining the present invention, and should not be construed as limiting the present invention.

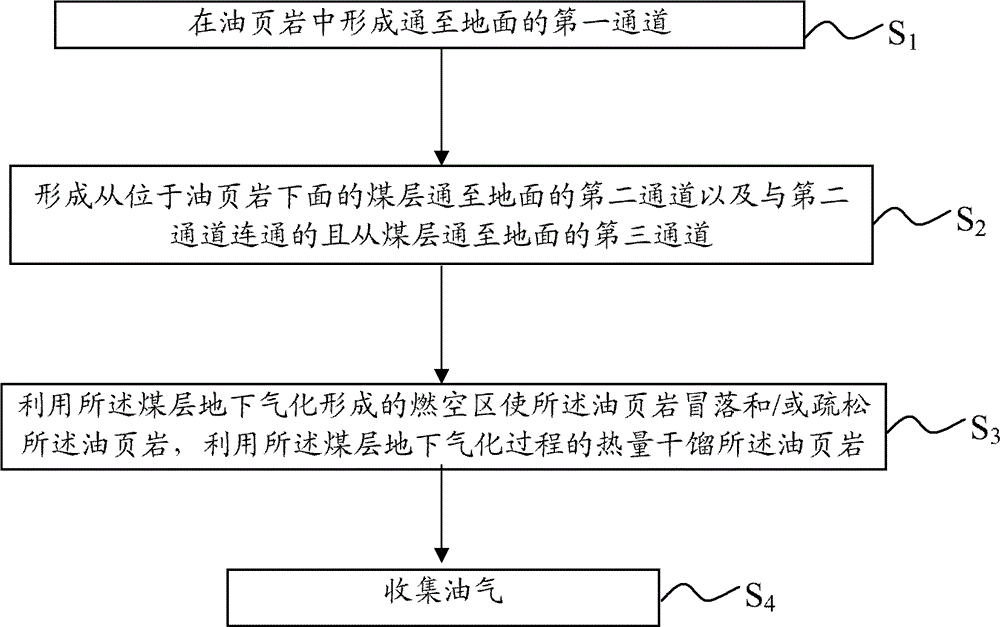

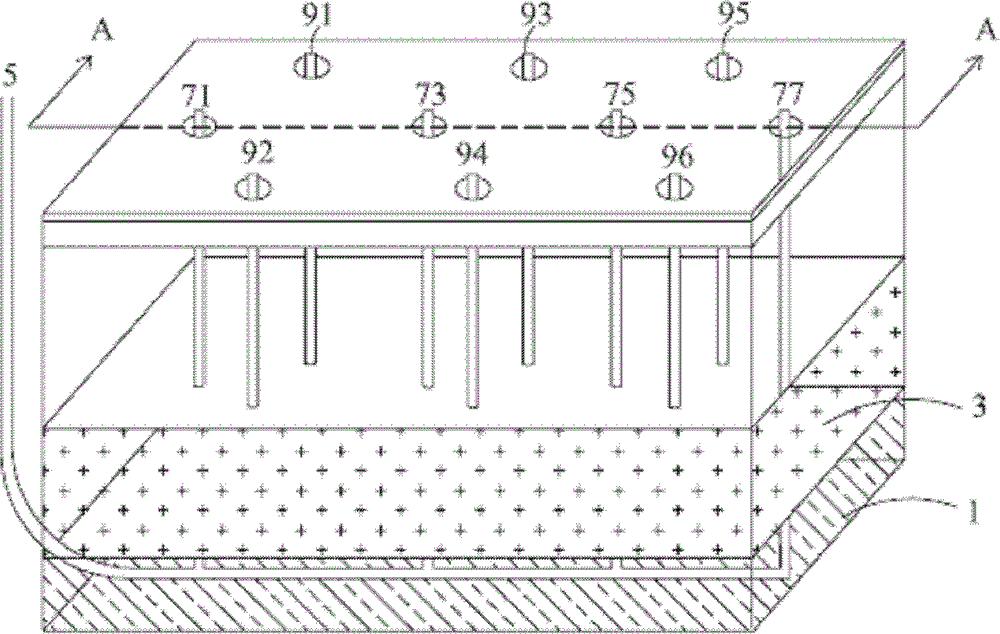

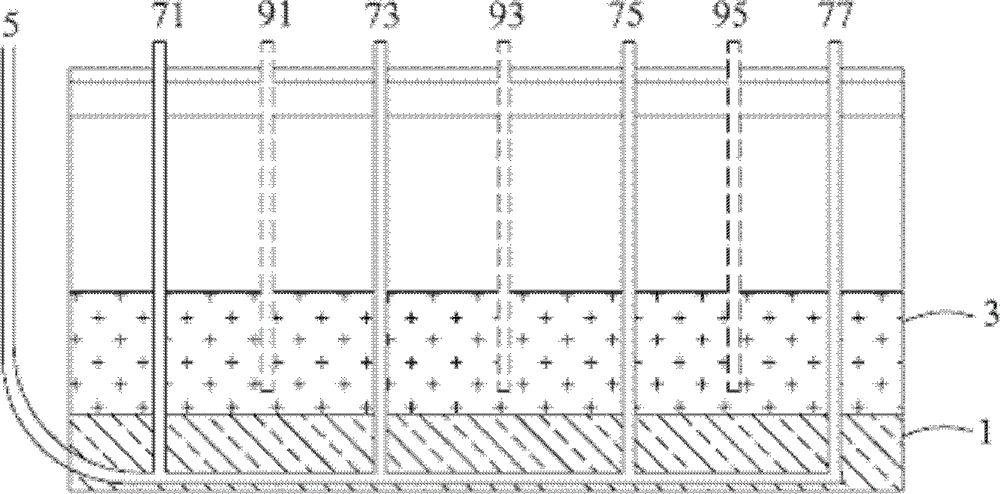

[0043] figure 1 It is a flow chart of the oil shale mining method according to the present invention. Such as figure 1 As shown, according to the present invention, the first channel 91-96 leading to the ground is formed in the oil shale 3 (as figure 2Shown) (step S1), as oil and gas collection holes. And, in the coal seam 1 below the oil shale 3, form the second channel 71,73,75 leading to the ground (such as figure 2 As shown), the gas inlet and outlet holes are used to gasify the coal seam 1, and the second channel can a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com