Steel rail or bridge displacement monitoring device for fiber Bragg grating transformation ring

A fiber grating and displacement monitoring technology, which is applied in the field of rail or bridge displacement monitoring devices and rail displacement, can solve the problems of unstable sensor characteristics, decreased sensor sensitivity, and inability to realize automatic measurement, so as to achieve long-term maintenance of measurement accuracy and solve the problem of stability Problems, Effects of Simple Structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

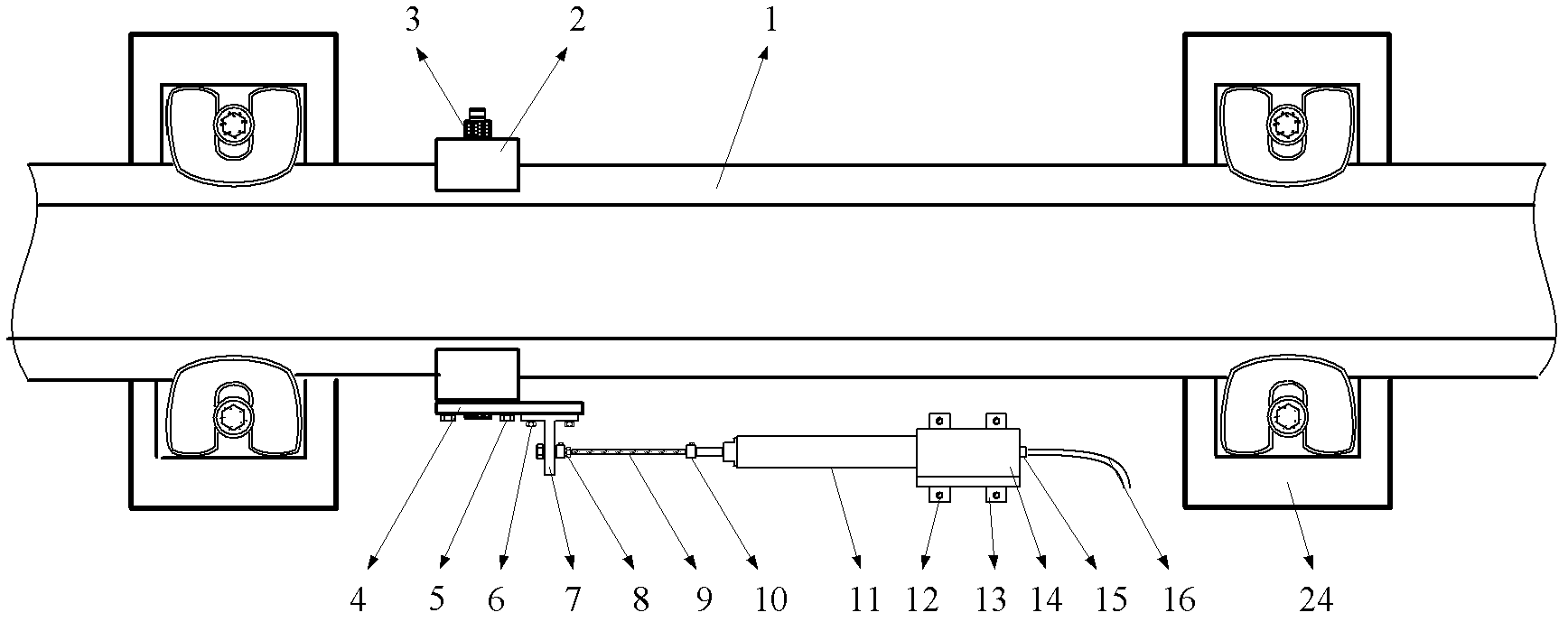

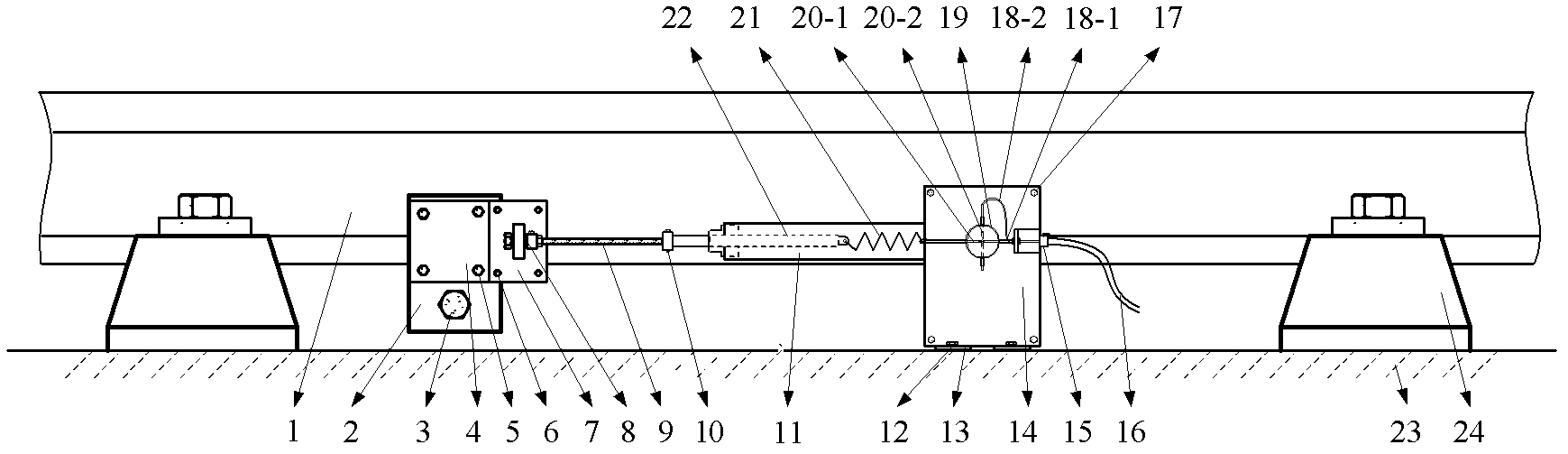

[0031] The structure and installation method of the rail displacement monitoring device of the optical fiber grating deformation ring of the present invention will be further described below in conjunction with the accompanying drawings.

[0032] Such as figure 1 , 2 As shown, the monitoring device is composed of a fixing clip assembly, a connecting assembly, a fiber grating annular displacement sensing assembly, a pull rod assembly and a sensor housing device. When monitoring rail displacement, the whole device is installed between two sleepers 24 .

[0033]The fixing clip assembly is fixed on both sides of the bottom of the rail 1 by the rail fixing clip 2 and the fixing clip fastening bolt 3, and it is required to be fastened without looseness to ensure the accuracy of displacement measurement. The steel plate 4 is fixed on the outside of the rail clamp 2 (i.e. the outside of the rail) with the fastening bolt 5 of the steel plate 4, and the connecting cable fixing frame ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com