Large-current collector ring device of generator

A collector ring and high current technology, applied in the direction of electromechanical devices, electrical components, etc., can solve the problems of small number of conductive screws, poor current distribution uniformity, and small current carrying capacity, and achieve uniform current distribution, manufacturing difficulty and material cost. The effect of reducing and increasing the current carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing:

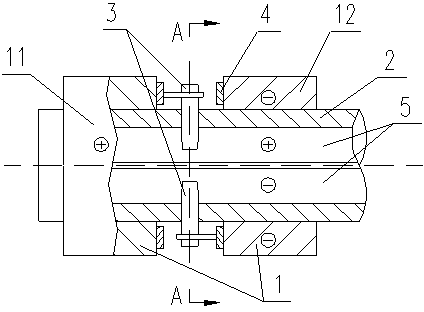

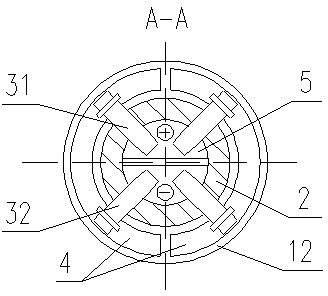

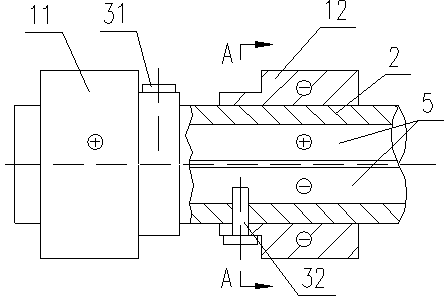

[0022] Generator high-current slip ring device, including slip ring (positive pole) 11, slip ring (negative pole) 12, and current sharing ring 4 arranged on the rotor, used to connect the conductive rod 5 and current sharing ring 4 in the rotor Conductive screw 3, each current sharing ring 4 is composed of 2 half-rings to form a whole ring, which is combined on the side of the collector ring 1, covering the 360° angle of the side of the collector ring 1, and each half-ring is correspondingly equipped with a conductive screw 3 , connected to the same pole of the conductive rod 5 in the rotor through the conductive screw 3, each current sharing ring 4 is connected to two conductive screws 3, and the four conductive screws 3 of the two collector rings 1 are symmetrically arranged on the center of the rotor on the same axial section.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com