Sound film detection method and detection system for implementing detection method

A detection method and sound film technology, applied in measuring devices, instruments, electrical components, etc., can solve the problems of unreliable inspection quality, low inspection efficiency, and backward inspection methods, and achieve reliable inspection quality, high inspection efficiency, and simple operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

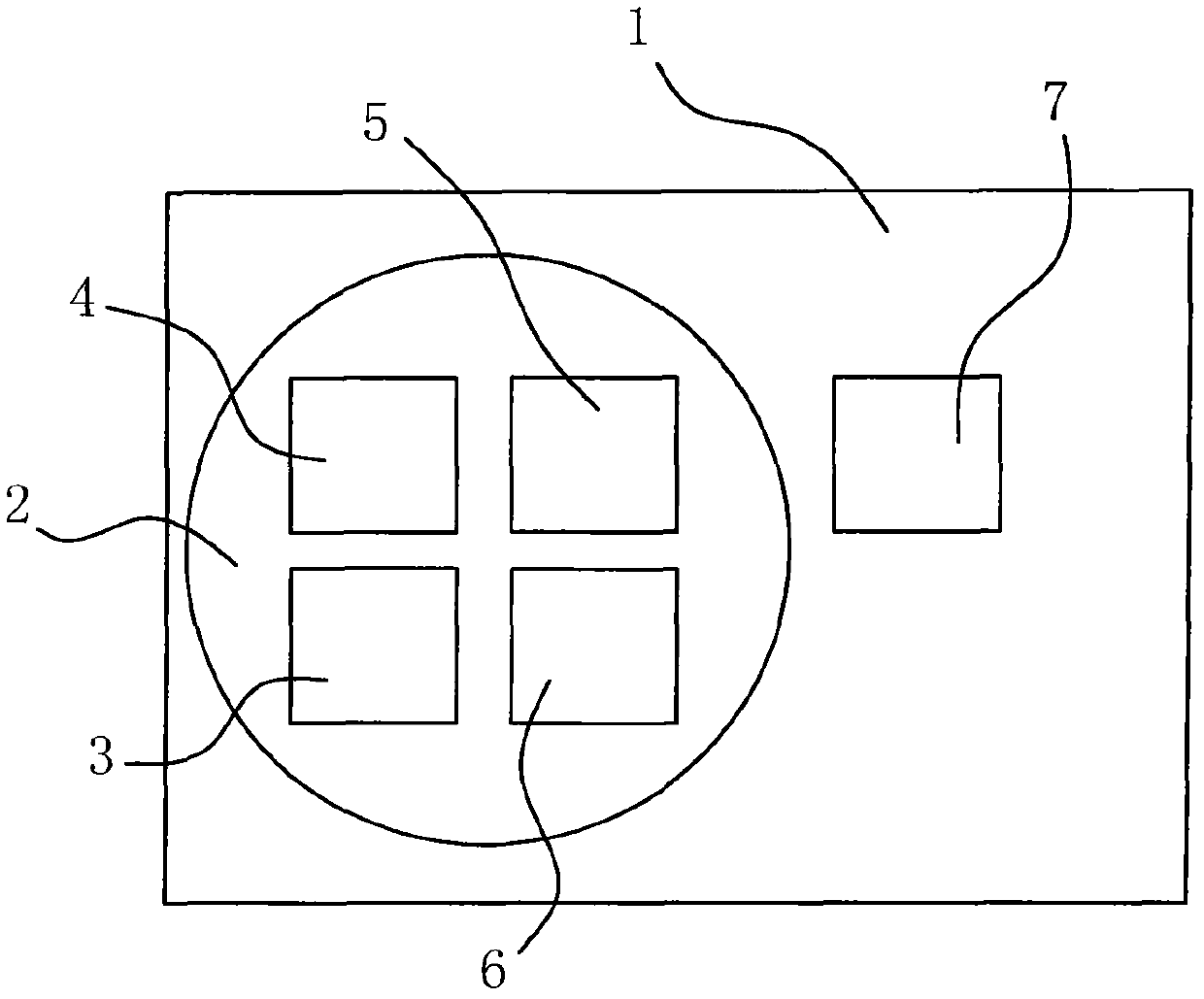

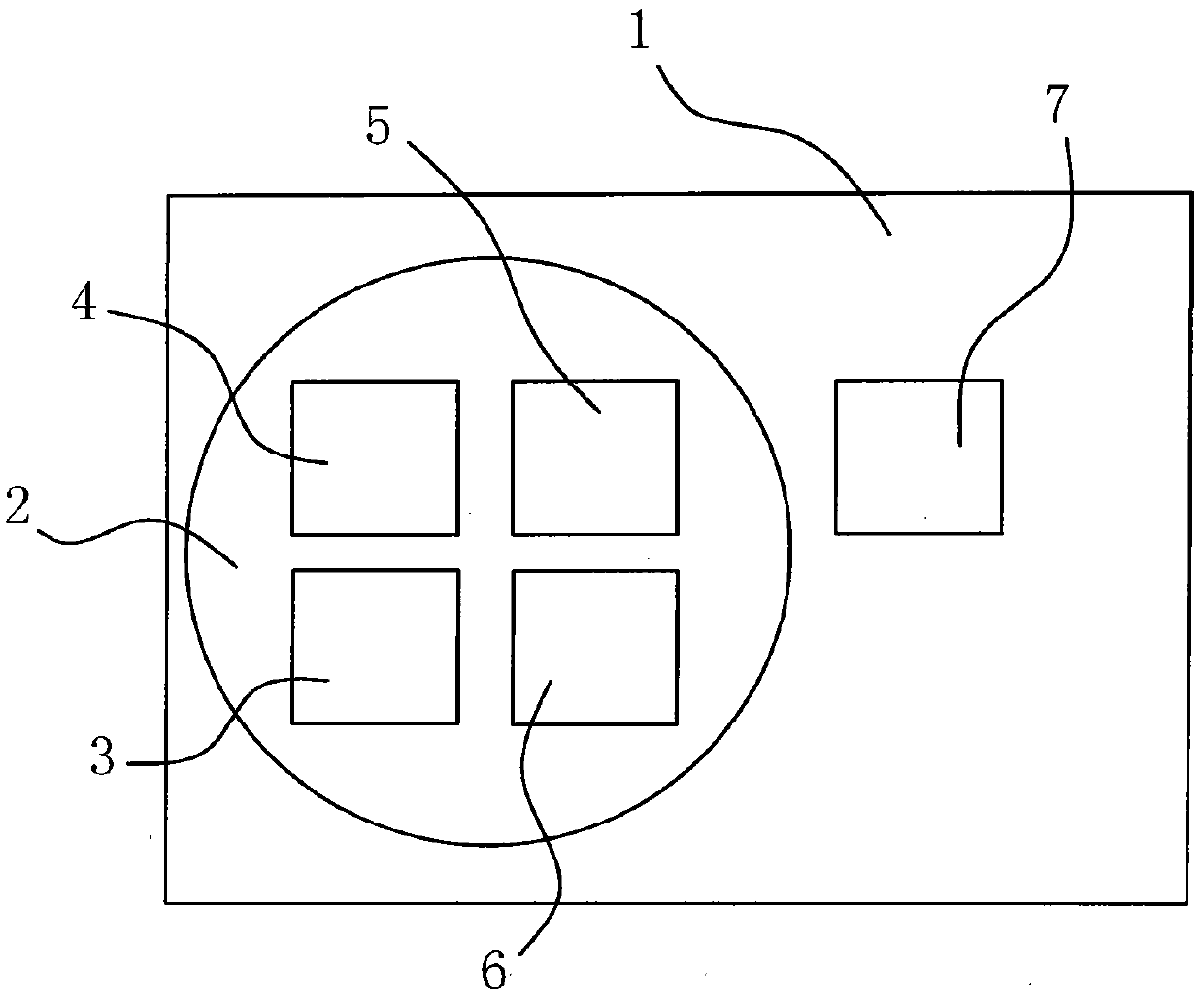

[0028] Example: see figure 1 , a kind of sound film detection method of the present invention, it comprises the following steps:

[0029] (1) a workbench 1 is set, a turntable 2 driven by a turntable motor is set on the workbench 1, a feeding station 3, a photographing station 4, a photographing station 4, A rejecting station 5 and a discharging station 6, a defective product station 7 is set on one side of the rejecting station 5, and the five stations have the same size and shape;

[0030] (2) On the top of the turntable 2 facing the photographing station 4, a camera driven by a servo motor is set parallel to the surface of the turntable 2 and can move along the X and Y axis directions;

[0031] (3) facing the rejecting station 5 above the turntable 2, and parallel to the surface of the turntable 2, a suction cup driven by a servo motor that can move along the X, Y, and Z axis directions is set;

[0032] (4) a vision controller is set, the vision controller is electrically...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com