Partridge tea liquid beverage

A partridge tea and partridge tea technology, which is applied in the direction of tea substitutes and the like, can solve the problems of short product shelf life, single partridge tea product, and difficult product quality control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

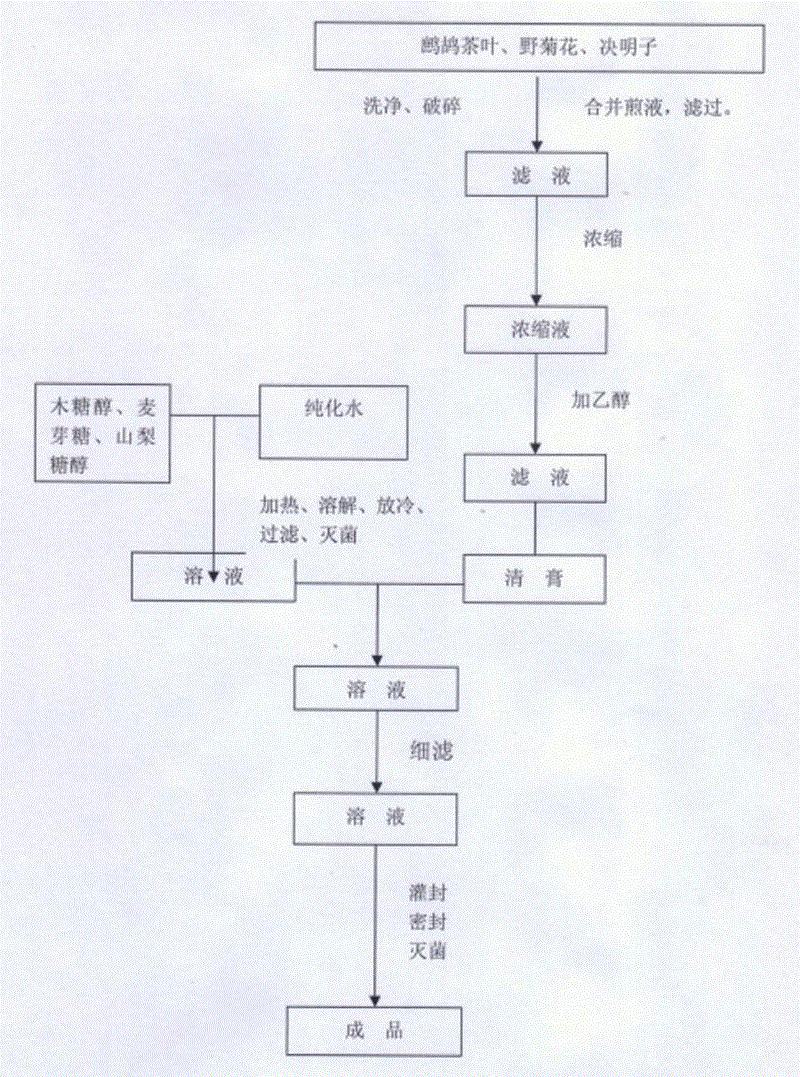

Method used

Image

Examples

Embodiment 1

[0020] Take 500g of wild chrysanthemum, 2000g of partridge tea leaves, and 700g of cassia seeds, remove moldy tea leaves and impurities, wash them in cold water, dry them, break them into pieces about 1-2cm in length, add 30-45 times the amount of water respectively, Decoct in a functional extraction tank or sandwich pot for 2-3 times, 30-50 minutes each time, then combine the decoction liquid and filter it with a plate and frame filter. Filter material specifications: 80-300 mesh stainless steel screen; use reduced pressure concentration Concentrate the filtrate under reduced pressure to a relative density of 1.00-1.30 (45-60°C); add 85-95% ethanol to make the ethanol content in the solution reach 30-45%, let it stand for 24-30 hours, and use a plate and frame filter Filtration, filter material specifications: 80-300 mesh stainless steel screen; use a vacuum concentration tank to recover ethanol and concentrate to a relative density of 1.00-1.40 at 50-60°C to obtain a clear pa...

Embodiment 2

[0022] Repeat the steps and process of Example 1, but adjust the ratio of various raw materials: 1000g of wild chrysanthemum, 3600g of partridge tea, 1000g of cassia seed, 1000g of maltose, 4500g of xylitol, 1000g of sorbitol, and the packaging dosage is adjusted to The can is 330ml, and the sterilization time is 50 minutes.

Embodiment 3

[0024] Repeat the steps and process of Example 1, just adjust the proportioning of various raw materials: 750g of wild chrysanthemum, 2800g of partridge tea leaves, 850g of cassia seed, 750g of maltose, 3300g of xylitol, 750g of sorbitol, and the packaging dosage is adjusted to each The can is 310ml, and the sterilization time is 40 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com