Young barley grass superfine powder making process

A production process and superfine powder technology, applied in the field of food processing, can solve the problems of absorption, high cost, loss of effective components of barley seeds, etc., and achieve the effect of simple process and lowering blood sugar.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

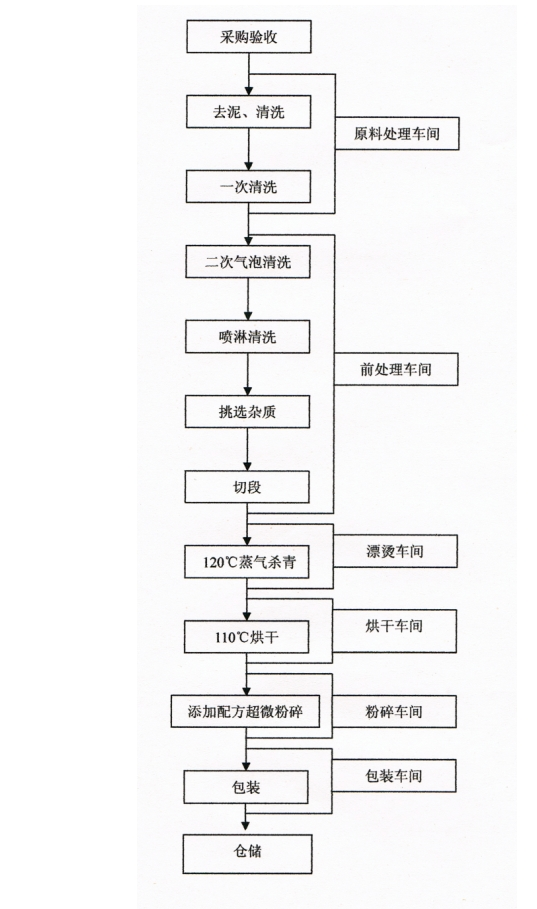

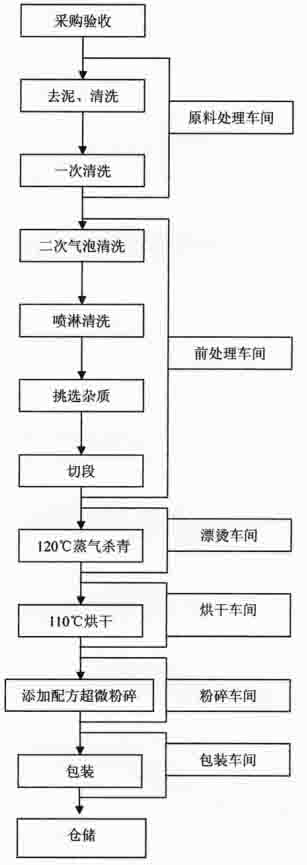

[0007] This specific embodiment adopts the following technical solutions: it passes through purchase acceptance, mud removal cleaning, primary cleaning, secondary bubble cleaning, spray cleaning, selection of impurities, section cutting, 120°C steam cleaning, 110°C drying, adding The formula is made through the steps of superfine pulverization, packaging and storage.

[0008] The superfine pulverization of the added formula includes the following steps: the first step is to mechanically pulverize the dried barley grass for the first time to 4-16 mesh; The material enters the low-temperature air (range 110-130MPa) flow pulverizer. Obtain 50% barley flour with a particle size of 20 to 40 microns; the third step is to feed the secondary air (range 150 to 170 MPa) flow mill at a constant speed of 3KG per minute to obtain 50% barley flour with a particle size of 0.3 to 1.0 microns barley flour.

[0009] In the formula process of this specific embodiment, five ten-thousandths of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com