Comprehensive utilization method for waste water and fibroid dregs generated from arrowroot production

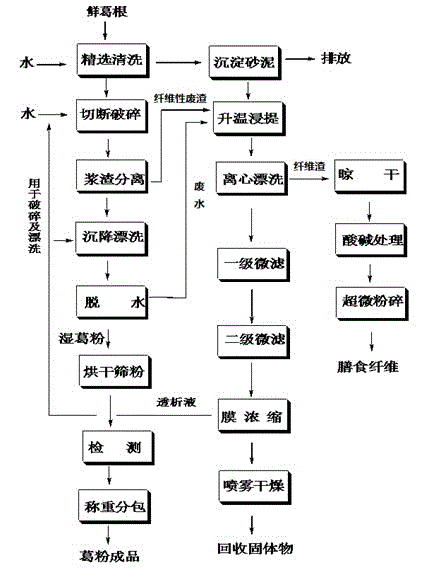

A fibrous and kudzu powder technology, which is applied in the field of extracting and recycling plant active ingredients, can solve the problems of high energy consumption, damage, and waste of the environment, and achieve the effects of retaining active ingredients, saving water resources, and ensuring recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Take 1 kg of fresh kudzu, remove the rotten part, clean it, chop it up, use about 8 kg of water, squeeze and crush it, add water to wash the powder, filter, put the slurry into the settling tank, settle for 12 hours, separate the mother liquor, and remove sand And with about 3 kilograms of water rinsing sedimentation starch 3 times, sedimentation 3 hours after each rinsing, take out wet starch temperature control 70~80 ℃ of vacuum drying 4 hours, get dry arrowroot starch 190 grams. During the above process, 12 kg of waste water (mother liquor and rinsing liquid) and some fibrous waste residue (about 0.2-0.3 kg) are produced.

[0048] Add the fibrous waste residue to a 20L jacketed glass kettle with agitation, add all 12 kg of waste water, heat the jacketed hot water to a temperature of 50°C in the kettle under stirring, keep it warm for leaching for 1 hour, and filter while it is hot to obtain the filtrate and fiber slag, the fiber slag is rinsed and dried with about 1 ...

Embodiment 2

[0050] Get 2 kilograms of fresh kudzu, carry out the powder operation by embodiment one, get kudzu powder 382 grams, 25 kilograms of waste water and some fibrous waste residues.

[0051] Add fibrous waste residue to a 20L jacketed glass kettle with stirring, add about 12.5 kg of waste water, and under stirring, heat the jacketed hot water to a temperature of 50°C in the kettle, heat preservation and leaching for 2 hours, and centrifuge while it is hot to obtain centrifuge Liquor and fiber slag, the fiber slag is leached once again according to the above conditions, centrifuged, rinsed with an appropriate amount of water and dried for subsequent use. Combine the centrifuge and lotion, and carry out microfiltration, membrane concentration, and spray drying according to Example 1 to obtain 65 grams of solid recovery. The puerarin content was 12% as detected by HPLC, and the recovery rate of puerarin was 0.39%.

Embodiment 3

[0053] Get 3 kilograms of fresh kudzu, carry out the powder operation by embodiment one, get kudzu powder 571 grams, 37 kilograms of waste water and some fibrous waste residues.

[0054] Add fibrous waste residue to a 20L jacketed glass kettle with stirring, add about 12.5 kg of waste water, under stirring, heat the jacketed hot water to a temperature of 50°C in the kettle, heat-preserve and extract for 3 hours, and centrifuge while it is hot to obtain centrifuged Liquor and fiber slag, the fiber slag is leached twice according to the above conditions, centrifuged, rinsed with an appropriate amount of water, and the fiber slag is taken out and dried for later use. The centrifuged liquid and washing liquid were combined, and microfiltration, membrane concentration, and spray drying were carried out according to Example 1 to obtain 102 g of solid recovered product. The puerarin content was 12% as detected by HPLC. The recovery rate of puerarin was 0.41%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com