Method for preparing rose extract for supercritical CO2 extraction cosmetics

A rose extract, supercritical technology, applied in cosmetic preparations, cosmetics, cosmetic preparations, etc., can solve the problems of lack of beneficial effects of rose extract, limited solubility of rose extract, and inability to improve extraction yield, etc. The human body and its skin are obviously beneficial, improving the use value, and the effect of good smell and color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The supercritical CO 2 The preparation method of extracting rose fragrance for cosmetics is characterized in that: using rosebuds with a water content of 12.0%, crushing them into a raw material powder with a particle diameter of 80 meshes, and using emu oil with a weight of 0.2% of the raw material powder as an entrainer and raw material powder Mix evenly, and then send the mixture into the supercritical extraction kettle, and input CO into the supercritical extraction kettle 2 The fluid is extracted at an extraction pressure of 35MPa and an extraction temperature of 70°C for an extraction time of 0.5 hours, and then the CO containing the dissolved components of the raw material powder in the supercritical extraction kettle 2 The fluid is introduced into the supercritical separation tank, and the CO 2 Separation, separation time is 0.5 hours, separation to remove CO 2 After that is the prepared rose extract for cosmetics.

Embodiment 2

[0019] The supercritical CO 2 The preparation method for extracting rose fragrance for cosmetics is characterized in that: using rose buds with a water content of 6.0%, crushing it into a raw material powder with a particle diameter of 10 meshes, using emu oil with 20% weight of the raw powder as an entraining agent and the raw material powder Mix evenly, and then send the mixture into the supercritical extraction kettle, and input CO into the supercritical extraction kettle 2 The fluid is extracted at an extraction pressure of 15MPa and an extraction temperature of 25°C for 5 hours, and then the CO containing the dissolved components of the raw material powder in the supercritical extraction kettle is extracted 2 The fluid is introduced into the supercritical separation tank, and the CO 2 Separation, separation time is 0.5 hours, separation to remove CO 2 After that is the prepared rose extract for cosmetics.

Embodiment 3

[0021] The supercritical CO 2 The preparation method for extracting rose fragrance for cosmetics is characterized in that: using rose buds with a water content of 8.0%, crushing it into a raw material powder with a particle diameter of 45 meshes, and using emu oil with a weight of 5% of the raw material powder as an entraining agent and raw material powder Mix evenly, and then send the mixture into the supercritical extraction kettle, and input CO into the supercritical extraction kettle 2 The fluid is extracted at an extraction pressure of 25MPa and an extraction temperature of 40°C for an extraction time of 2 hours, and then the CO containing the dissolved components of the raw material powder in the supercritical extraction kettle 2 The fluid is introduced into the supercritical separation tank, and the CO 2 Separation, separation time is 2 hours, separation to remove CO 2 After that is the prepared rose extract for cosmetics.

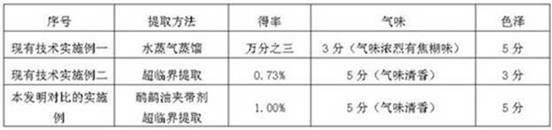

[0022] The following is a comparison test ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com