Method for processing Fischer-Tropsch synthesis tail gas

A technology for Fischer-Tropsch synthesis and exhaust gas treatment, which is applied in air quality improvement, separation methods, and dispersed particle separation to achieve the effect of saving investment and improving utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0021] Process description

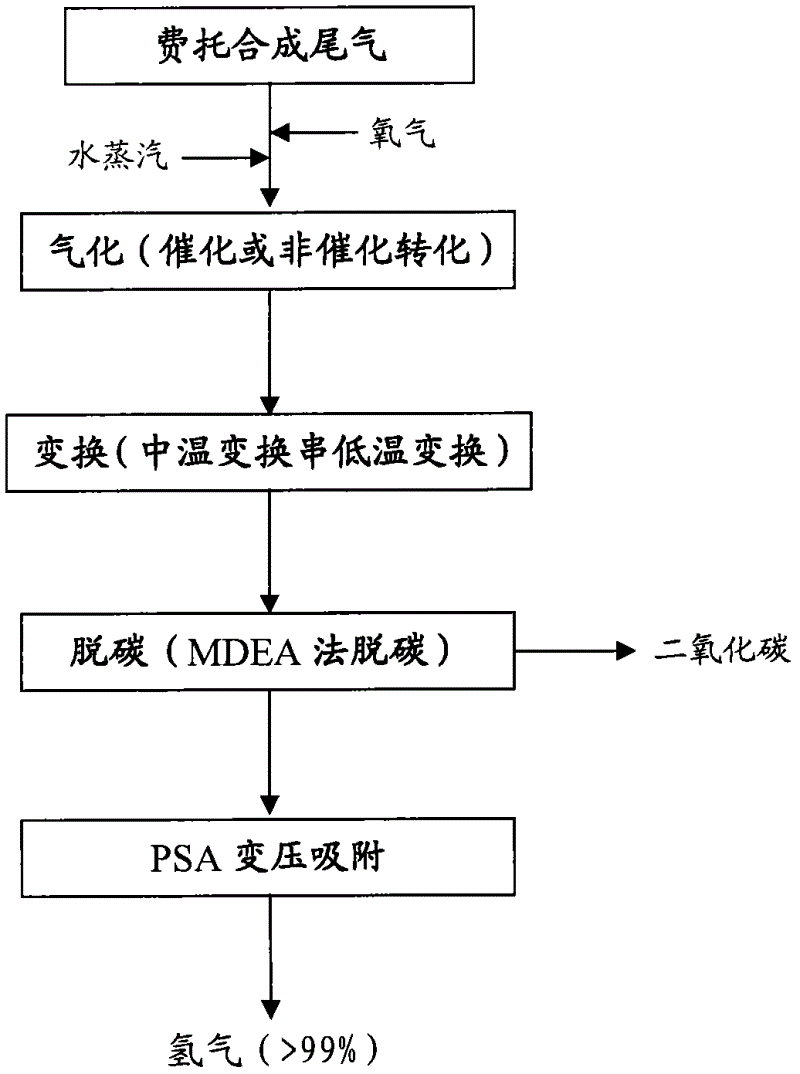

[0022] Such as figure 1 The flow diagram shown is the whole process of Fischer-Tropsch synthesis tail gas treatment in this patent, which includes four process steps of partial oxidation of light hydrocarbons, shifting, decarburization, and PSA pressure swing adsorption.

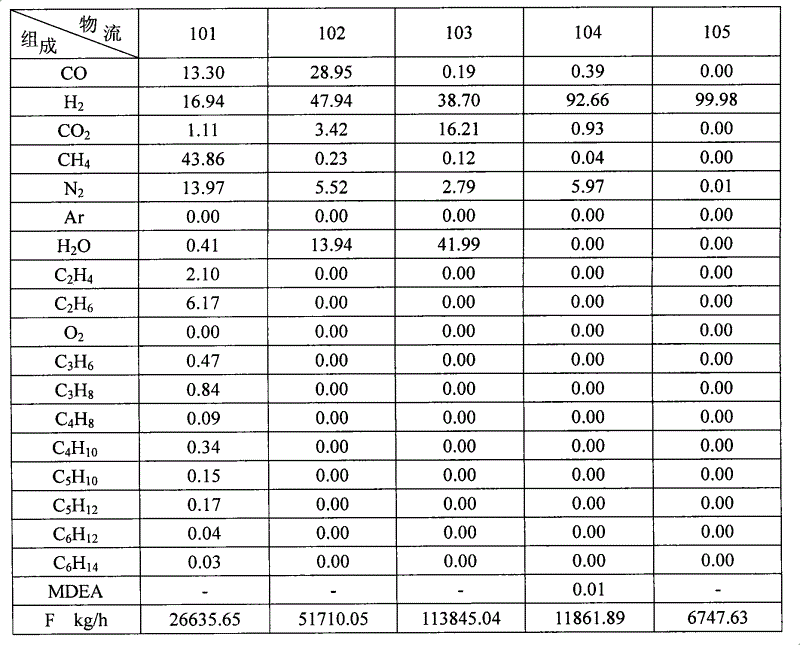

[0023] 1) Partial oxidation of light hydrocarbons: the oxygen (flow 19816.4kg / h, temperature 40°C, pressure 5.1MPa) and water vapor (flow 5258kg / h, pressure higher than 4.2MPa) from the air separation are passed into the waste to be treated In the Tropsch synthesis tail gas (flow rate 26635.6kg / h, temperature 40°C, pressure 4.2MPa, see stream 101 for the composition), catalytic conversion is used at an operating temperature of 1200°C to convert the low-carbon hydrocarbons and other carbon-containing compounds contained in the tail gas to change ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com