Flexible printing machine added with quality inspection substandard-product rejecting device

A flexographic machine and motor technology, applied in the field of flexographic machines, can solve the problems affecting the work efficiency and product quality of enterprises, low production efficiency, etc., and achieve the effects of shortening the production cycle of products, improving the yield, and avoiding the decline of credibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

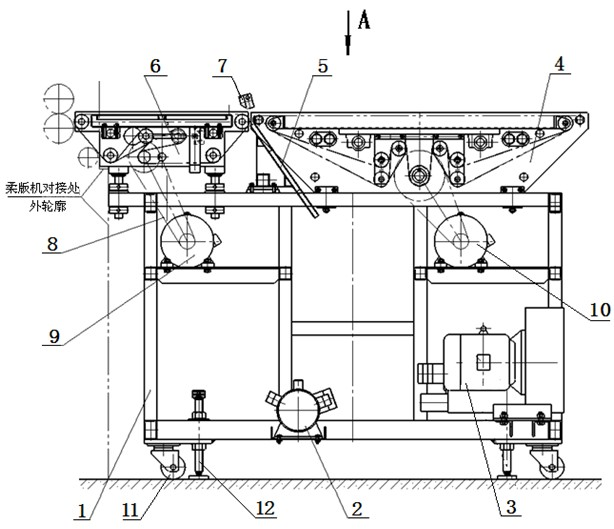

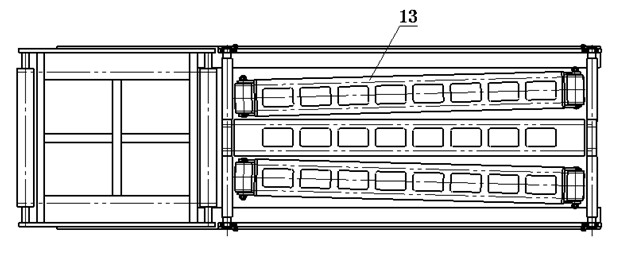

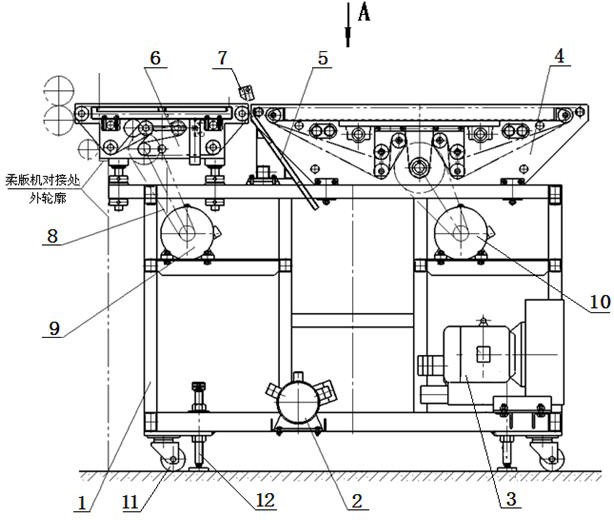

[0025] In this embodiment, a quality inspection and picking device is added to the flexo printing machine, including a primary adsorption transport platform 6 and a secondary adsorption separation transport platform 4 installed on the upper end of the mobile frame 1, a primary adsorption transport platform 6 and a secondary adsorption separation transport platform. The drive shaft of the platform 4 is respectively connected with the first three-phase asynchronous motor 9 and the second three-phase asynchronous motor 10 through a synchronous toothed belt, and the terminal of the first-stage adsorption conveying platform 6 and the second-stage adsorbing and separating conveying platform 4 is provided with Picking and falling device 5, the upper part of picking and dropping device 5 is equipped with picking air knife 7, and picking air knife 7 is connected with the air circuit electromagnetic reversing valve, which is controlled by the air circuit electromagnetic reversing valve to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com