Numeric control worm-gear hobbing machine

A hobbing machine and worm gear technology, applied in the field of CNC worm gear hobbing machines, can solve the problems of high labor cost, high noise, and time-consuming replacement, and achieve the effects of improving production efficiency, accurate processing accuracy, and reducing manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

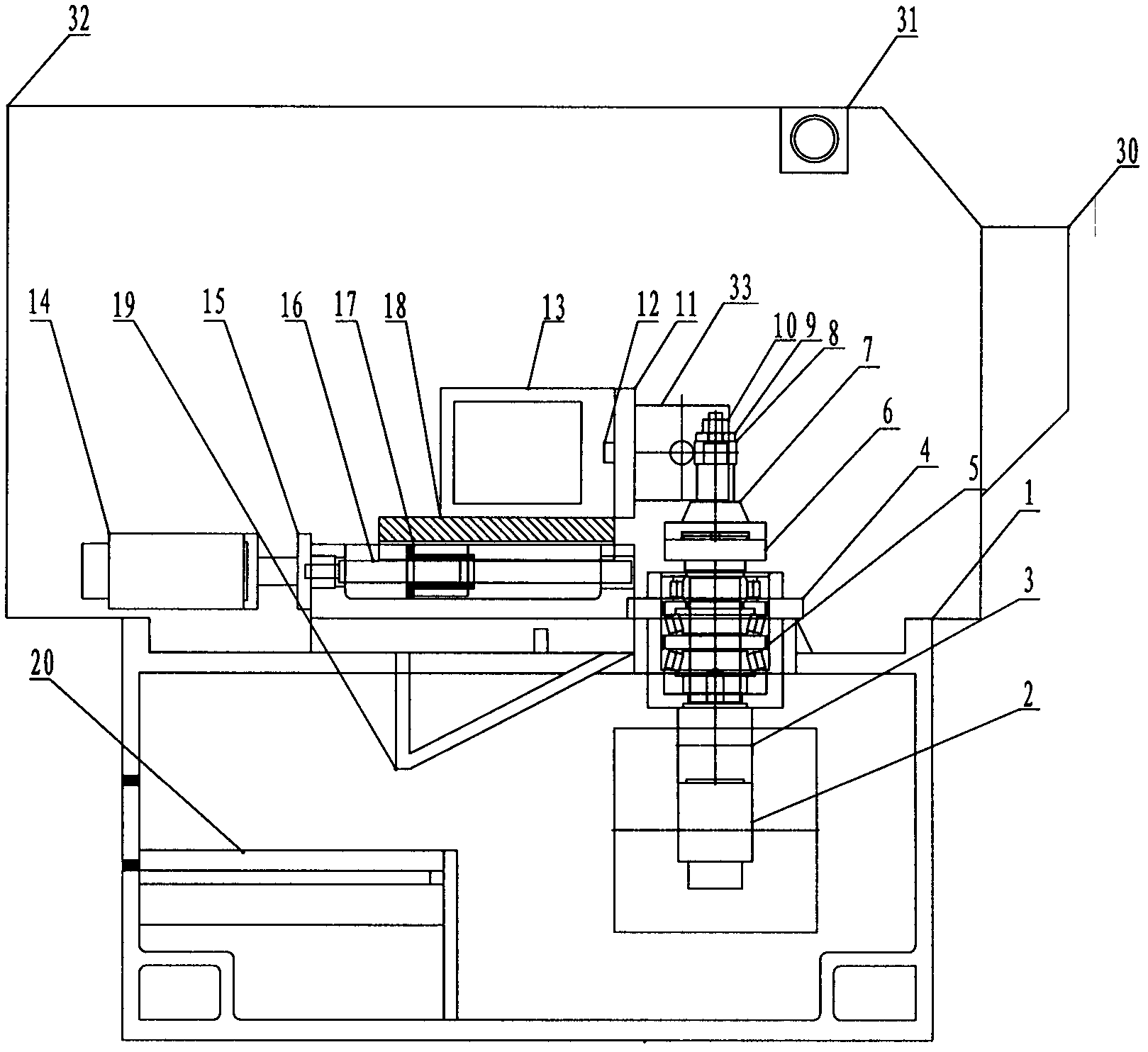

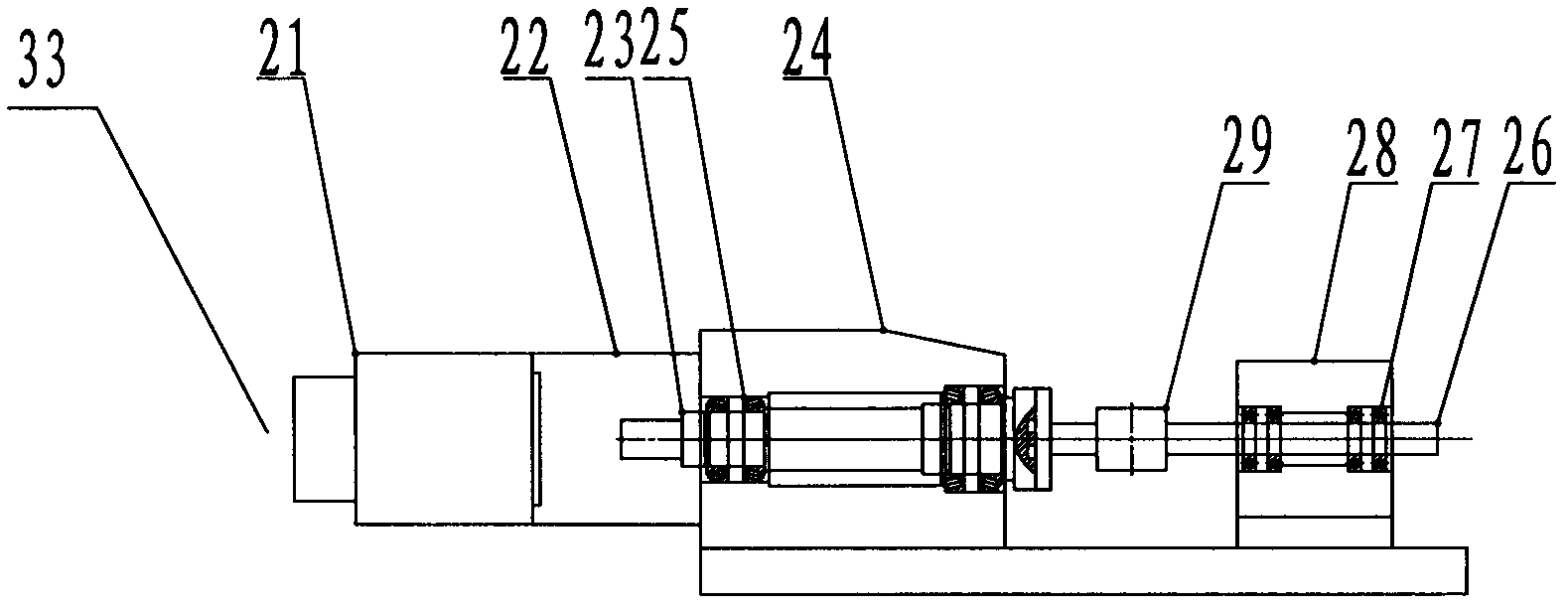

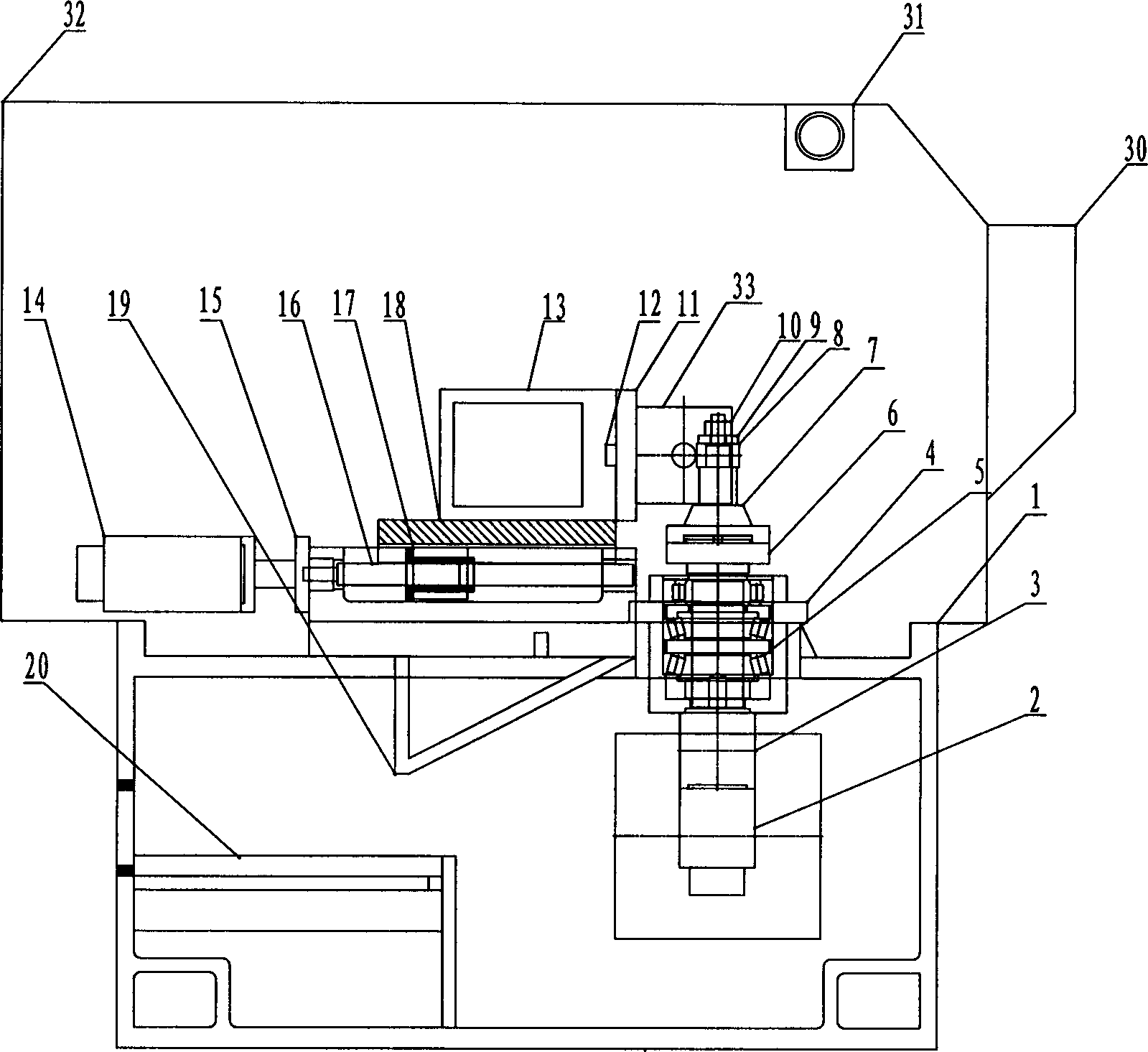

[0023] see figure 1 , a numerical control worm gear hobbing machine, comprising a machine tool base 1, a servo motor 2 arranged in the machine tool base 1, the servo motor 2 is connected to a reducer 3, the reducer 3 is connected to a box 4, and the box 4 provides stable support for the main shaft 6 And provide the installation space of bearing 5. A bearing 5 is installed in the box body 4, and the main shaft 6 is inserted into the bearing 5 to connect with it. The servo motor 2 provides a power source for the main shaft 6 through the reducer 3 . The box body 4 provides stable support for the main shaft 6 and a space for installing the bearing 5 . The machine base 1 is used to support the weight of the machine tool itself and ensure the smooth operation of the machine tool.

[0024] A workbench 7 is installed on the main shaft 6, and the workbench 7 is installed with a workpiece 8 to be processed, and the workpiece 8 is fixed by a compression nut 10 and a compression end co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com