Perforated TIG (Tungsten Inert Gas) arc melting brazing method of dissimilar metal

A dissimilar metal, melting and brazing technology, applied in the direction of arc welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of difficulty in spreading liquid metal, uneven structure and performance of brazing interface, etc., achieve low cost and reduce brittleness Phase formation, good process stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

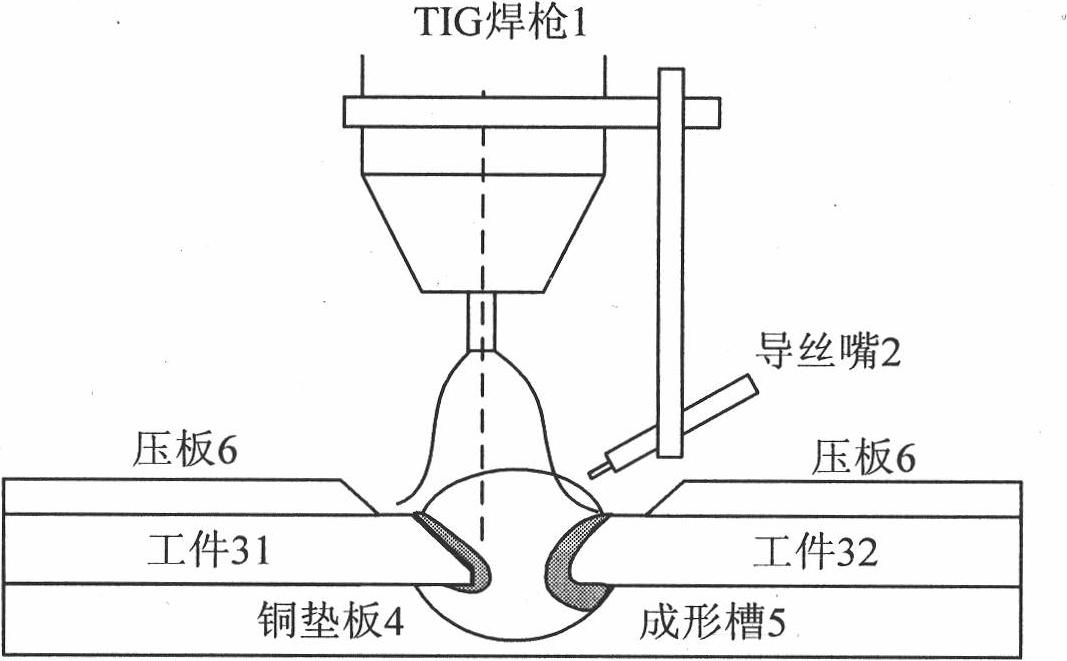

[0025] Example 1: Combining figure 1 , figure 2 , the perforated type TIG arc melting and brazing method of dissimilar metals of the present invention, realizes according to the following steps:

[0026] Step 1: Test workpiece and equipment preparation: 1 set of AC TIG welding machine, 1 set of inching wire feeder, 1 set of automatic walking mechanism, 1 piece of copper backing plate with forming groove, 1 set of rigid fixture, workpiece: workpiece ( 31) It is metal steel or titanium alloy with high melting point, Y-shaped groove is opened, the workpiece (32) is aluminum alloy with low melting point, and the welding wire: the diameter is 2.5-4mm;

[0027] Step 2: Clamp the steel / aluminum or titanium / aluminum sheets with rigid fixtures and copper backing plates, and assemble them into butt joints, ensuring that the gap matches the size of the forming groove to obtain a suitable rear forming size;

[0028] Step 3: Assemble the wire guide nozzle of the wire feeder with the wel...

Embodiment 2

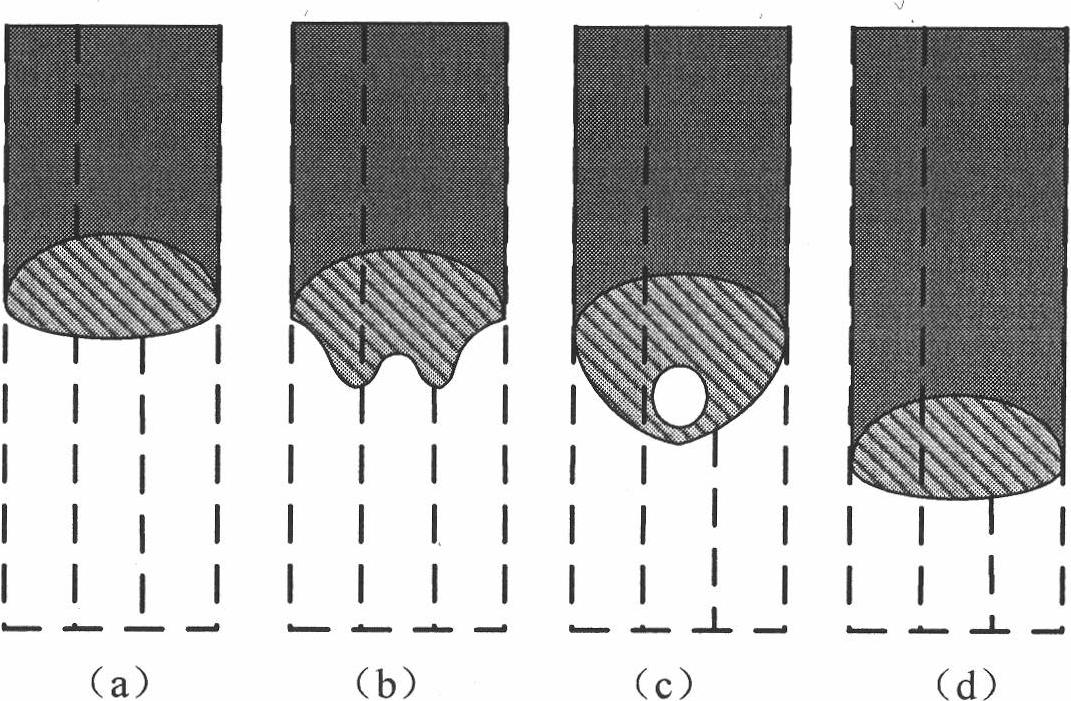

[0033] Example 2: Combining figure 2 , the perforated type TIG arc melting and brazing method of dissimilar metals of the present invention forms a dynamically changing molten pool: 1) weld seam solidification and workpiece heating, in the melting and brazing process, along with the welding torch moves forward, the liquid aluminum molten pool flows from the slope The mouth and the edge of the weld begin to solidify, forming an oval molten pool, such as figure 2 (a). At the same time, the TIG arc heats the groove, and the temperature of the groove gradually increases; 2) The perforated molten pool is formed, and after a period of heating by the TIG arc, the temperature inside the groove gradually increases. The number of electrode spots on the side of the high melting point workpiece (31) increases, and the electrode spots greatly reduce the interfacial tension, and the liquid metal gradually spreads forward along the groove of the workpiece (31). At the same time, the larg...

Embodiment 3

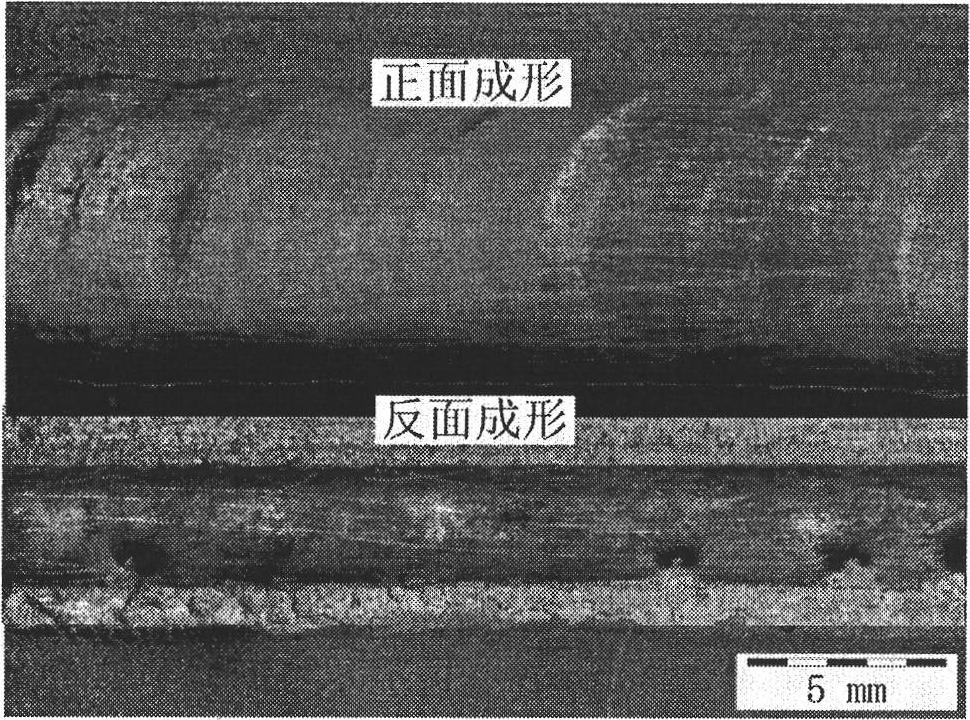

[0034] Example 3: Binding figure 1 , image 3 , taking the titanium alloy plate and aluminum alloy plate with a thickness of 2mm as the workpiece to be welded as an example to illustrate the implementation steps of this embodiment.

[0035] Step 1: Make a 45° unilateral bevel on the side of the titanium alloy, and process a 0.5mm blunt edge. The filling material is AlCu6 welding wire with a diameter of 3mm. The forming groove on the copper backing plate is 4mm wide and 3mm deep, and a MAG welding wire feeder is used. Carry out inching wire feeding;

[0036] Step 2: Clamp the titanium plate and the aluminum plate on the copper backing plate, so that the root gap of the butt joint groove is 1.5-2mm, and the groove gap is located above the center of the forming groove;

[0037] Step 3: Assemble the wire guide nozzle (2) of the wire feeder and the TIG welding torch (1) as one, and feed the wire from the aluminum alloy side at an angle of 30°. Place the TIG welding torch clamped...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com