Air flow pre-heater for water cooled wall of dilute nitric acid production process

A production process and water-cooled wall technology, applied in the field of dilute nitric acid production equipment, can solve problems such as difficult maintenance, reduced air volume, and increased evaporation load in the ammonium nitrate process, achieving the effects of increasing steam production, improving service life, and eliminating the risk of rupture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

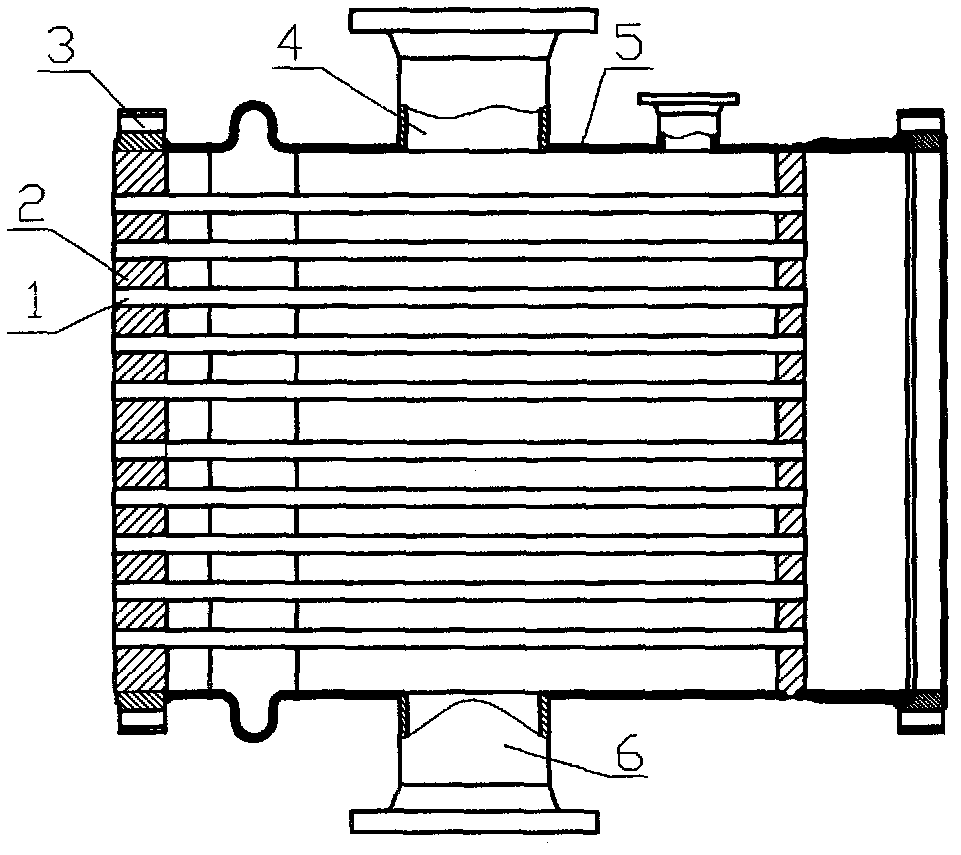

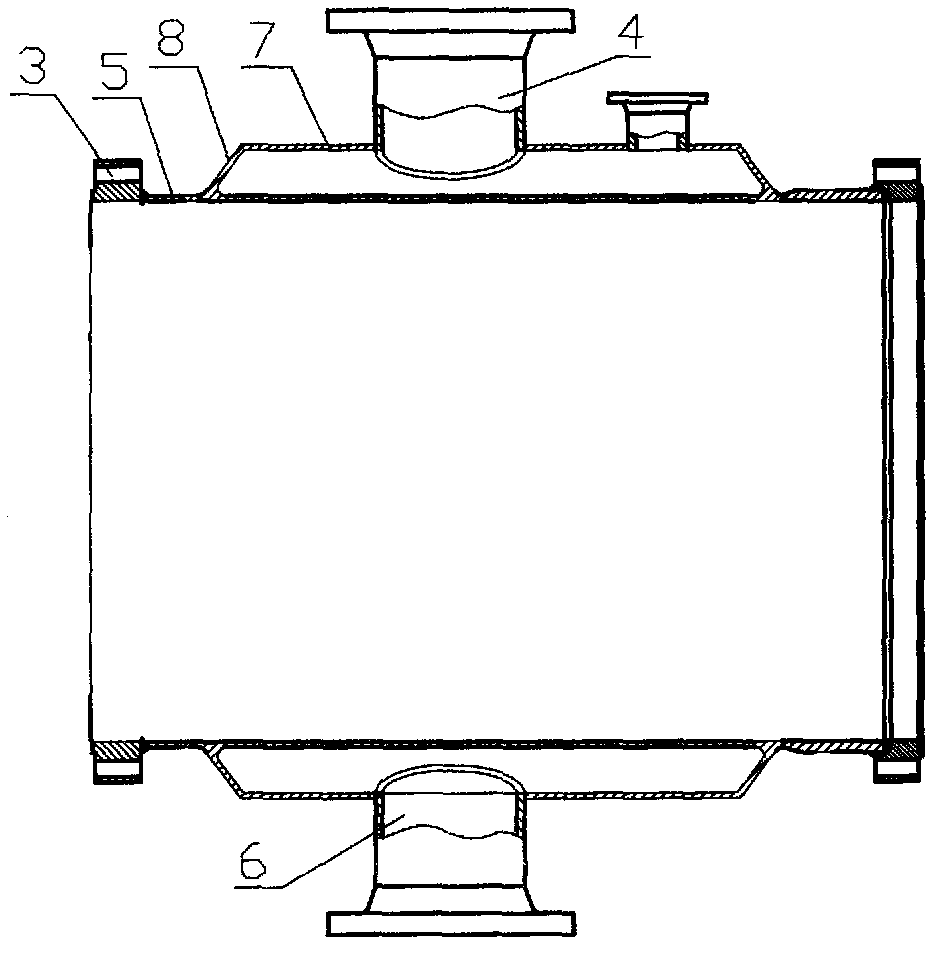

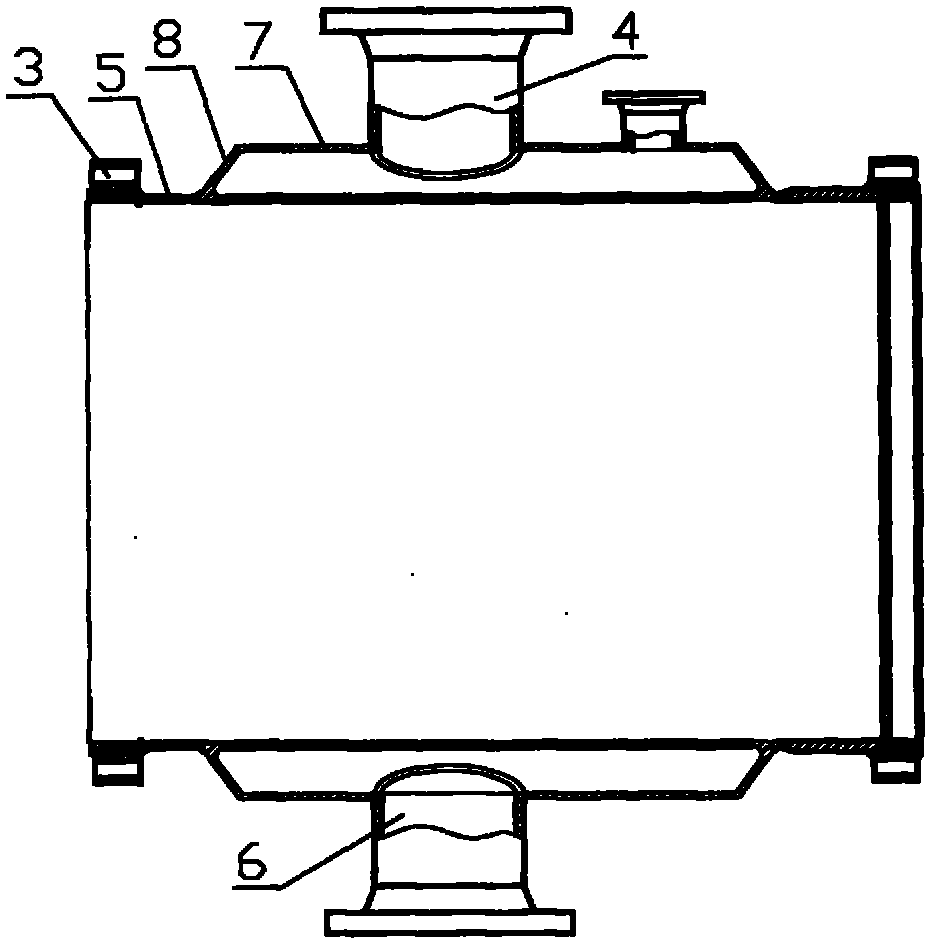

[0010] The invention includes a tubular body 5, a flange plate 3, a lower air intake pipe mouth 6, an upper exhaust pipe mouth 4, and a temperature measurement interface pipe respectively connected with the exhaust gas reheater output pipe and the waste heat boiler input pipe, and is characterized in that: tubular The inner cavity of the body 5 is a cavity; the two ends of the outer circle of the tubular body 5 are fixed with symmetrical tapered tubes 8, and the outer ports of the two tapered tubes 8 are fixedly connected with a round tube body 7 to form a ring-shaped water cooling chamber. The upper and lower through holes provided on the pipe wall of the body 7 are fixedly connected with the upper exhaust pipe port 4 and the lower air intake pipe port 6 respectively; the lower air intake pipe port 6 is connected with the bubble downcomer of the waste heat boiler, and the upper exhaust pipe port 4. It is connected with the bubble return pipe of the waste heat boiler; the tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com