BaO-TiO2 lead-free Y5U capacitor dielectric material and preparation method for same

A capacitor dielectric, ta2o5 technology, applied in the direction of fixed capacitor dielectric, fixed capacitor components, etc., to achieve the effect of optimizing synthesis and ball milling process and excellent dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] A kind of BaO-TiO described in the present invention 2 It is a lead-free Y5U capacitor dielectric ceramic material and its preparation method, combined with the content of the above invention, it will be further described by the following examples.

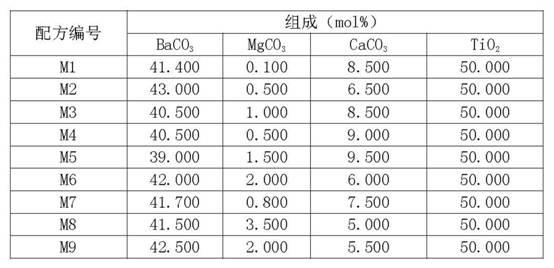

[0012] (1) with BaCO 3 , CaCO3, MgCO3, TiO 2 and other raw materials, according to the composition ratio of Table 1, according to the preparation process of the main material described in the summary of the invention, Ba (1-X-Y) Mg X Ca Y TiO 3 .

[0013] Table 1 Main material Ba (1-X-Y) Mg X Ca Y TiO 3 Example recipe of

[0014]

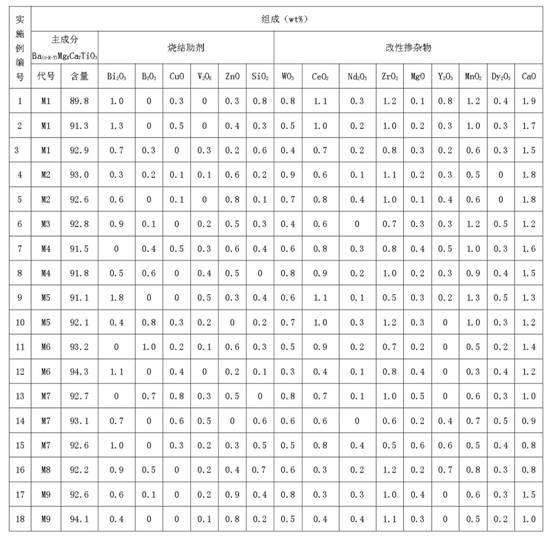

[0015] (2) According to the composition of Table 2, the main material is Ba (1-X-Y) Mg X Ca Y TiO 3 Where X=0.001~0.1mol, Y=0.001~0.2mol, add Bi 2 o 3 , B 2 o 3 , CuO, V 2 o 5 , ZnO, SiO 2 , Al2O3, MgO, Ta 2 o 5 , Nb 2 o 5 , MnO 2 , ZrO2, CaO, La2O3, Nd2O3, Y2O3, CeO2, WO3, Dy2O3, add deionized water in a ball mill for ball milling and mixing, and dry to obtain Y5U c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric properties | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com