Microbes for alkyl glycoside synthesis and application thereof

A technology of alkyl glycosides and microorganisms, which is applied in the field of alkyl glycoside synthesis and can solve the problems of undiscovered glucosidase and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Synthesis of methylglucoside catalyzed by Arthrobacter sp.DL001

[0039] The bacteria were inserted into the liquid medium at 120 rpm, cultured at 10°C for 60 hours, and then stored at -20°C.

[0040] The liquid medium used is: dextran 8g, KNO 3 1.2g, K 2 HPO 4 · 3H2O 1.5g, water 1000mL, NaOH to adjust the pH to 6.5-7.0.

[0041] Take 180 μl of the above fermentation broth, add 20 μl of 2% (w / v, the same below) starch solution and 10 μl of methanol, react in a constant temperature water bath at 20°C for 24 hours, then add an equal volume of 200 μl of methanol to terminate the reaction, centrifuge at 15000g*5min*4°C, and place on Qing is the product of transglycosylation.

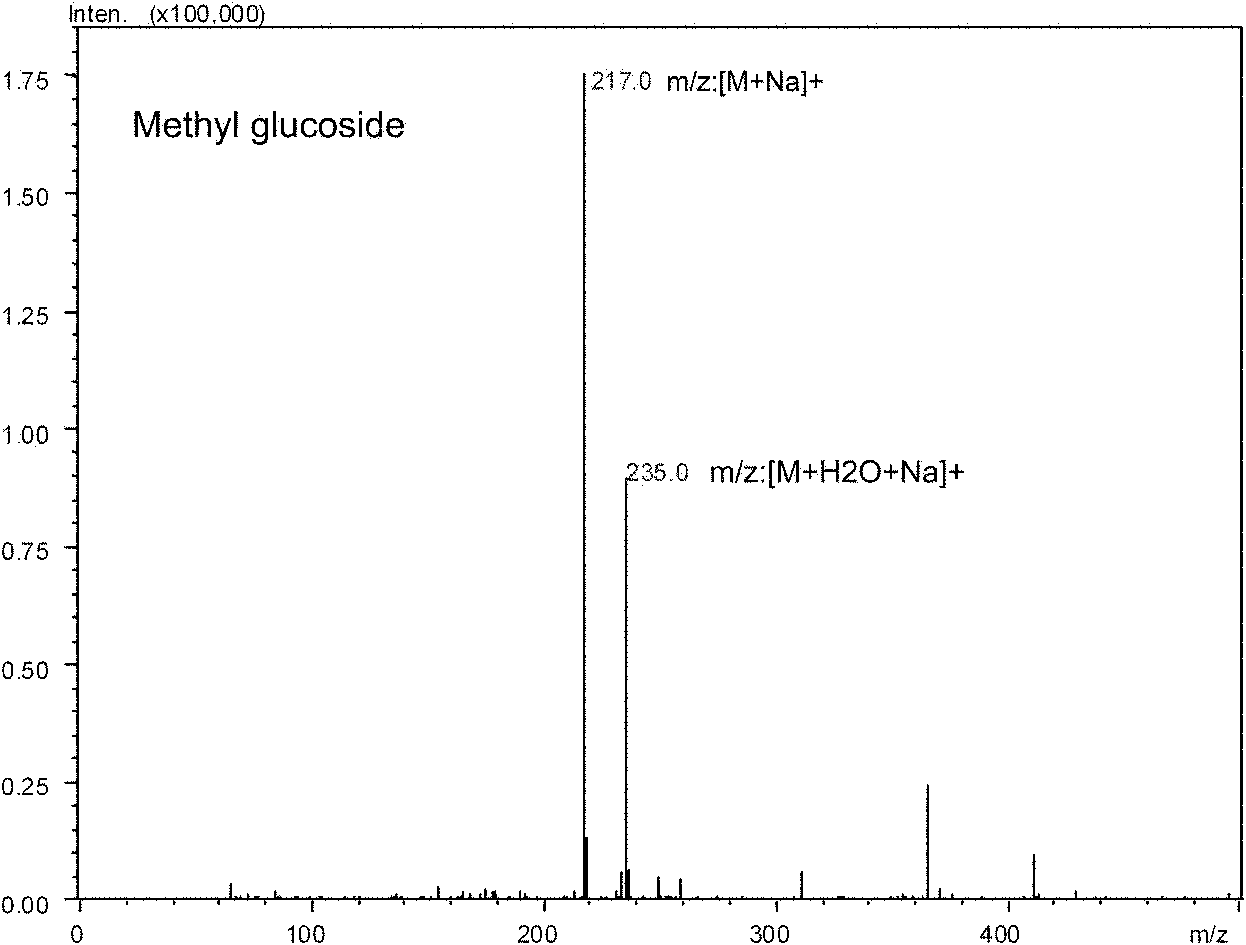

[0042] UFLC-MS identification was carried out on the supernatant obtained above, and the yield of the obtained product methyl glucoside was about 30%. The equipment and conditions used for the above UFLC-MS analysis: ultra-fast liquid chromatography (UFLC) system including CBM-20A system controll...

Embodiment 2

[0044] The synthesis reaction of n-butyl glucoside catalyzed by Arthrobacter sp.DL001 put the bacteria into the liquid medium at 200rpm, culture at 30°C for 45h, centrifuge the fermentation broth, and take the supernatant, which is the crude enzyme of glycosyltransferase solution, stored at -20°C.

[0045] The liquid medium used is maltose 20g, KNO 3 1g, K 2 HPO 4 ·3H 2 O 0.5g, water 1000mL, NaOH to adjust the pH to 7.4-7.6.

[0046] Take 1.8ml of the above fermentation broth, add 0.1ml of 10% (w / v, the same below) maltose, 0.1ml of n-butanol, react in a constant temperature water bath at 25°C for 5h, then add an equal volume of 2ml of methanol to terminate the reaction, centrifuge at 15000g*5min*4°C Finally, the supernatant is the transglycosylated product.

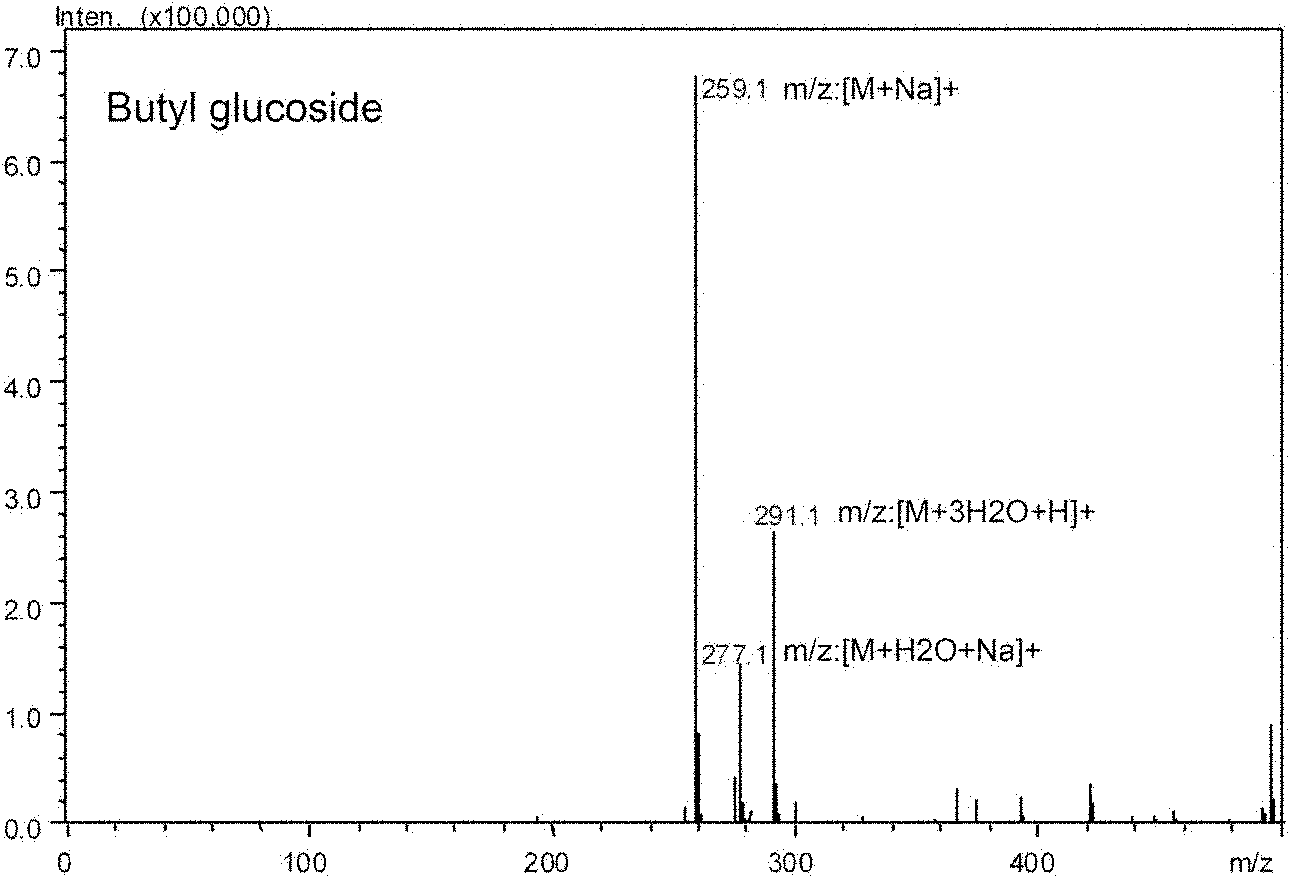

[0047] UFLC-MS identification was performed on the above-mentioned supernatant, and the equipment and parameters were the same as before. The yield of the obtained product n-butyl glucoside is about 50%.

Embodiment 3

[0049] Synthesis of Isopropylglucoside Catalyzed by Arthrobacter sp.DL001

[0050] Put the bacteria into the liquid medium at 250 rpm, culture at 35°C for 48 hours, centrifuge the fermentation broth, take the supernatant, which is the crude glycosyltransferase enzyme solution, and store it at -20°C.

[0051] The liquid medium used is: glucose 40g, NaNO 3 0.8g, K 2 HPO 4 ·3H 2 O 2g, water 1000mL, NaOH to adjust the pH to 7.0-7.5.

[0052] Take 180 μl of the above fermentation broth, add 10 μl of 20% (w / v, the same below) maltose, 5ul of isopropanol, react in a constant temperature water bath at 30°C for 2 hours, then add an equal volume of 200ul of methanol to terminate the reaction, centrifuge at 15000g*5min*4°C, The supernatant is the transglycosylated product.

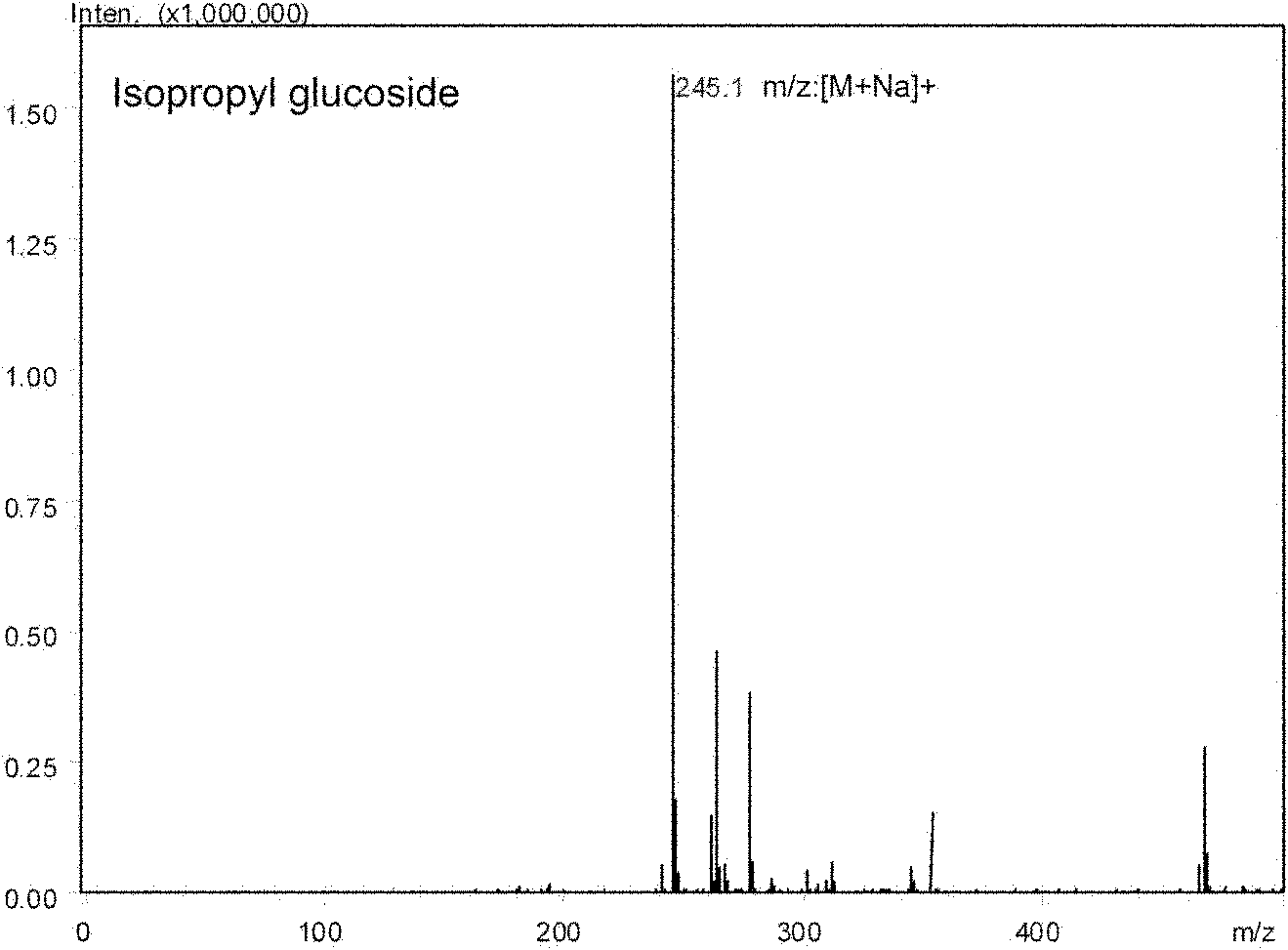

[0053] UFLC-MS identification was performed on the above-mentioned supernatant, and the equipment and parameters were the same as before. The yield of the product isopropylglucoside was about 40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com