Ytterbium and erbium-doped yttrium scandium gallium garnet crystal and preparation method thereof

A technology of gallium garnet and crystal, applied in the field of laser crystal and its preparation, can solve the problem that 940nm diode pumping cannot be applied, and achieve the effect of improving laser output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

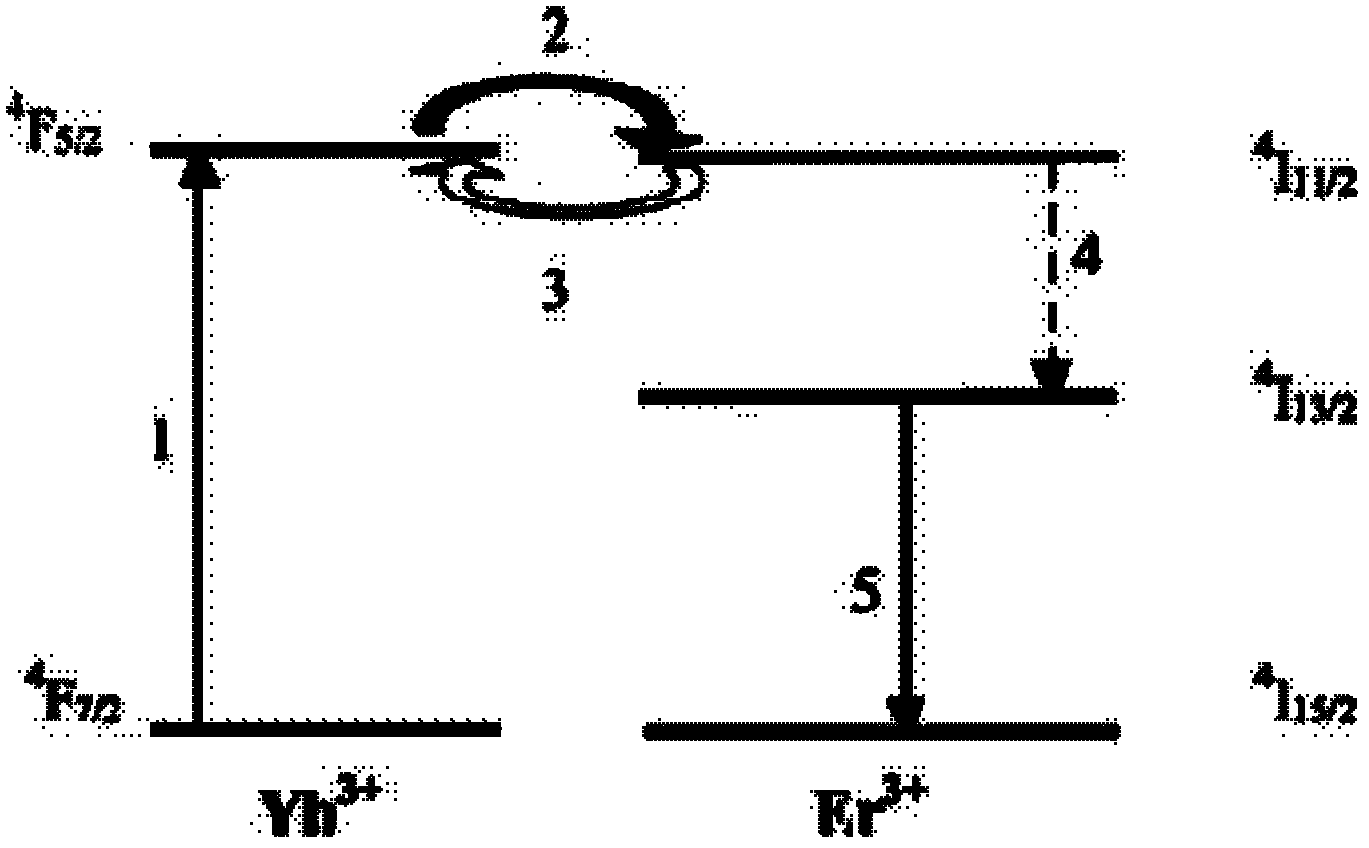

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0057] Preparation of crystal puller

[0058] Each oxide raw material Er 2 o 3 , Yb 2 o 3 , Y 2 o 3 、Sc 2 o 3 and Ga 2 o 3 Dehumidification, then according to the chemical formula Yb a Er b Y 3-a-b sc 2 Ga 3 o 12 Proportioning is calculated and weighed, wherein, a=0.15, b=0.9, and the total weight of raw materials is 2400g. The purity of each oxide is 5N-6N. Put each oxide raw material into a container, mix them evenly, put them into a latex bag, and statically press them into a hydraulic press. The pressed raw materials are loaded into a high-temperature furnace for polycrystalline material synthesis.

[0059] Preparation of Yb:Er:YSGG crystals (a=0.15, b=0.9)

[0060] Put the crystal pulling material into the crucible in the crystal growth furnace, the size of the crucible is ф90×90mm, and place 10g of desiccant P near the inner wall of the furnace 2 o 5 Then close the oven door.

[0061] Vacuum until the pressure in the furnace is not greater than 5×10 ...

Embodiment 2

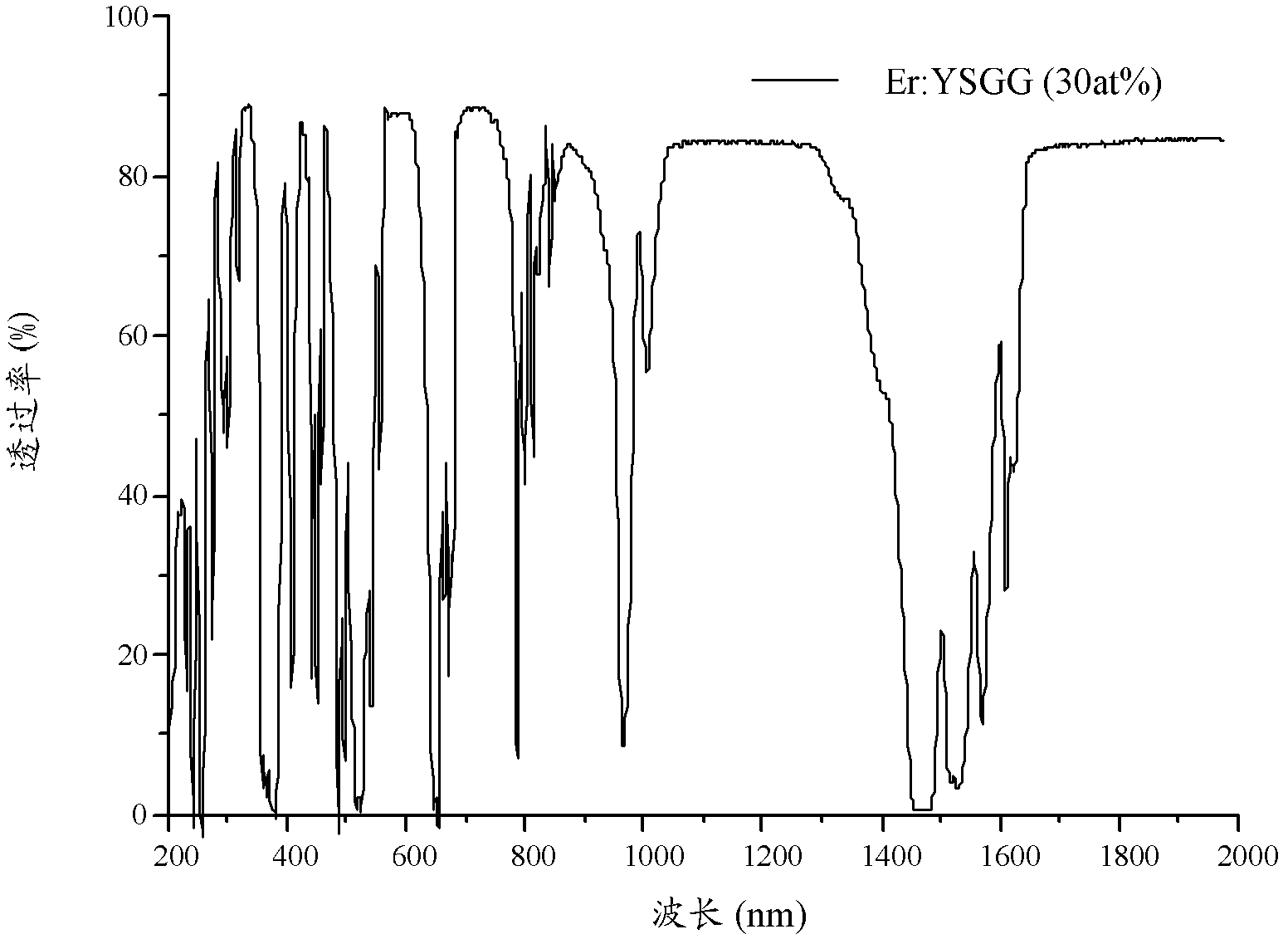

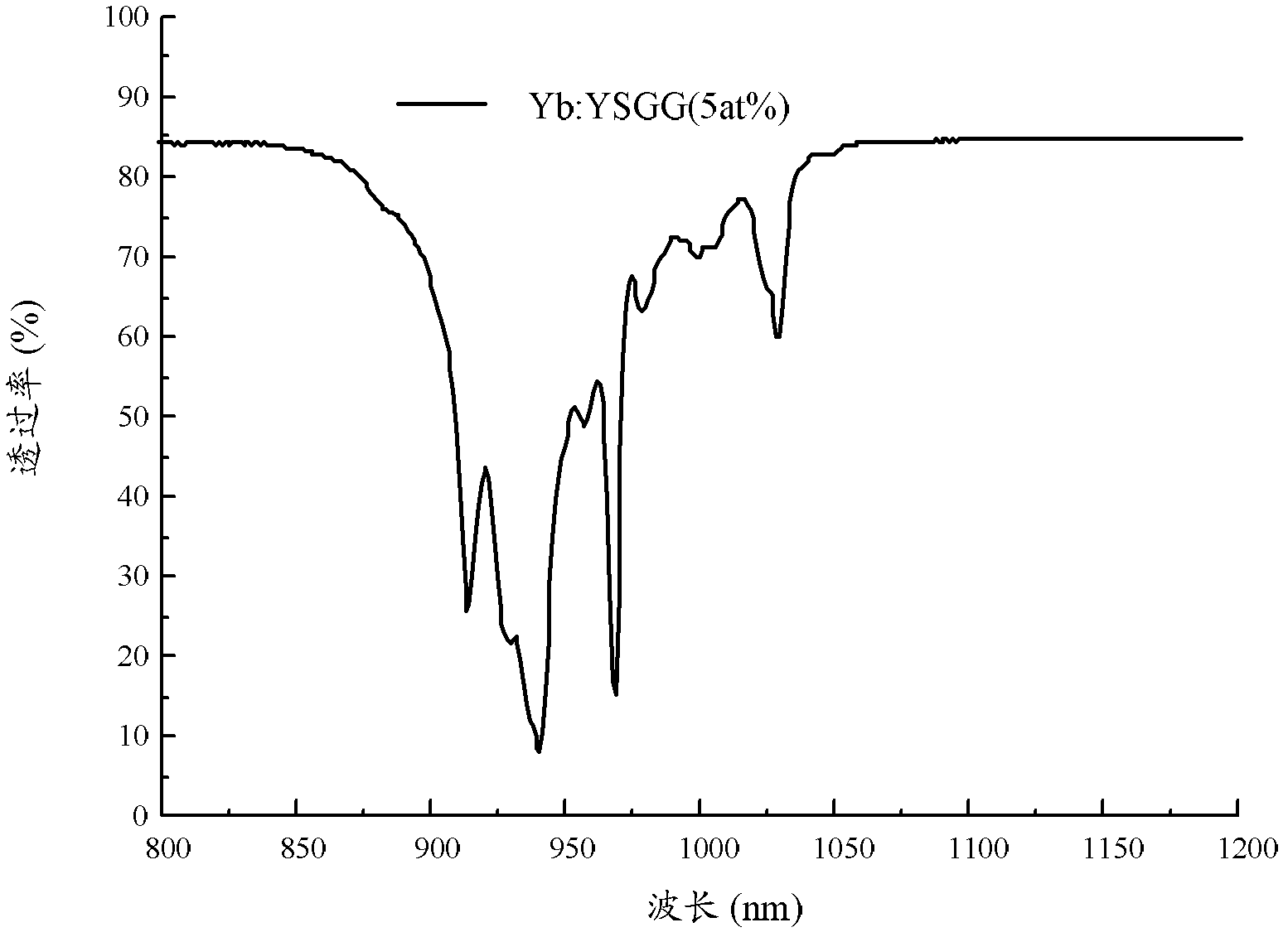

[0071] Preparation of crystal puller

[0072] Each oxide raw material Er 2 o 3 , Yb 2 o3 , Y 2 o 3 、Sc 2 o 3 and Ga 2 o 3 Dehumidification, then according to the chemical formula Yb a Er b Y 3-a-b sc 2 Ga 3 o 12 Proportioning is calculated and weighed, wherein, a=0.3, b=0.9, and the total weight of raw materials is 2400g. The purity of each oxide is 5N-6N. Put each oxide raw material into a container, mix them evenly, put them into a latex bag, and statically press them into a hydraulic press. The pressed raw materials are loaded into a high-temperature furnace for polycrystalline material synthesis.

[0073] Preparation of Yb:Er:YSGG crystals (a=0.3, b=0.9)

[0074] Put the crystal pulling material into the crucible in the crystal growth furnace, the size of the crucible is ф90×90mm, and place 20g of desiccant P near the inner wall of the furnace 2 o 5 Then close the oven door.

[0075] Vacuum until the pressure in the furnace is not greater than 5×10 -2 ...

Embodiment 3

[0085] Preparation of crystal puller

[0086] Each oxide raw material Er 2 o 3 , Yb 2 o 3 , Y 2 o 3 、Sc 2 o 3 and Ga 2 o 3 Dehumidification, then according to the chemical formula Yb a Er b Y 3-a-b sc 2 Ga 3 o 12 Proportioning is calculated and weighed, wherein, a=0.6, b=0.9, and the total weight of raw materials is 2400g. The purity of each oxide is 5N-6N. Put each oxide raw material into a container, mix them evenly, put them into a latex bag, and statically press them into a hydraulic press. The pressed raw materials are loaded into a high-temperature furnace for polycrystalline material synthesis.

[0087] Preparation of Yb:Er:YSGG crystals (a=0.6, b=0.9)

[0088] Put the crystal pulling material into the crucible in the crystal growth furnace, the size of the crucible is ф90×90mm, and place 5g of desiccant P near the inner wall of the furnace 2 o 5 Then close the oven door.

[0089] Vacuum until the pressure in the furnace is not greater than 5×10 -2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com