Novel solid laser

A solid-state laser, a new type of technology, applied in the laser field, can solve problems such as complex and expensive systems, unfavorable practical applications, and affecting laser output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with drawings and embodiments.

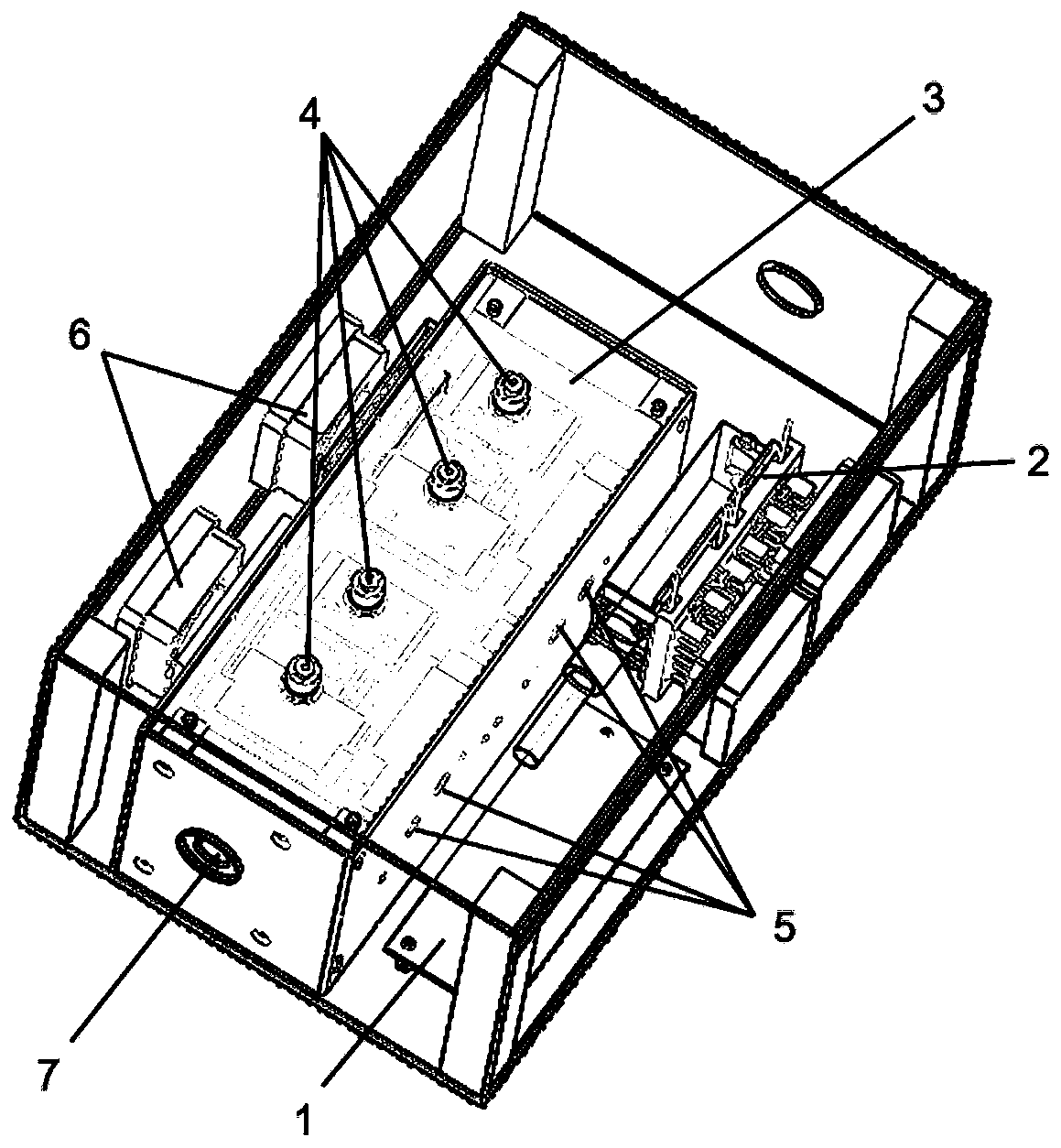

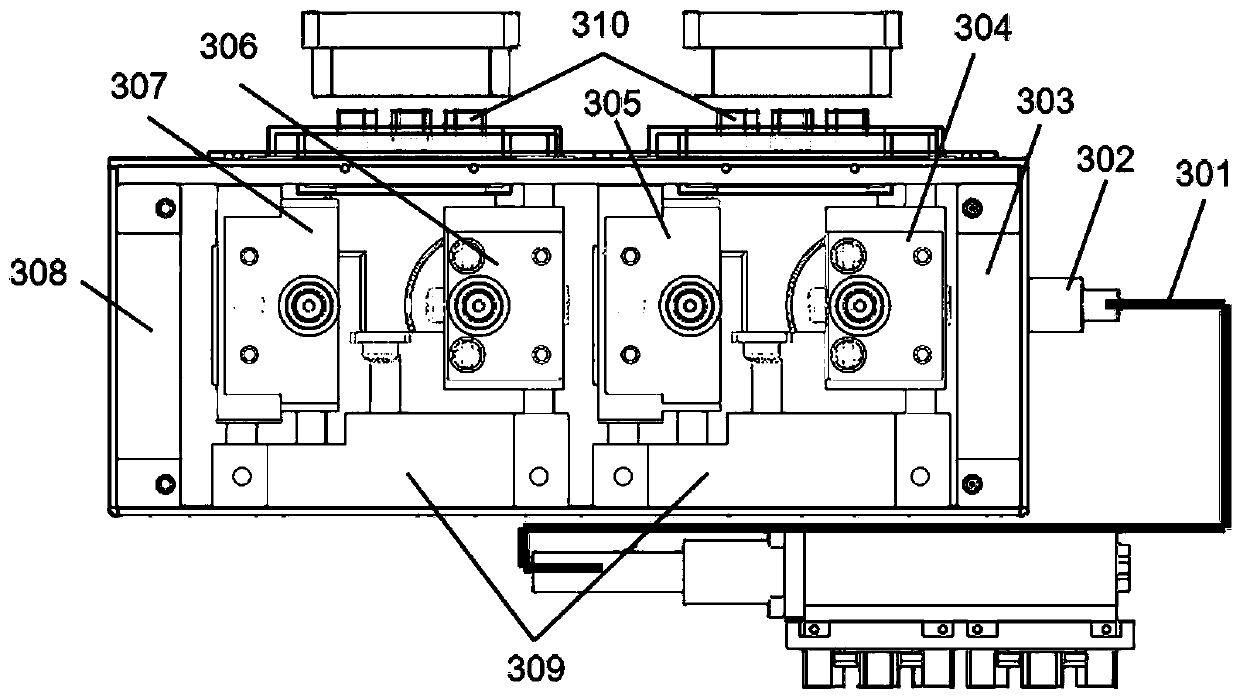

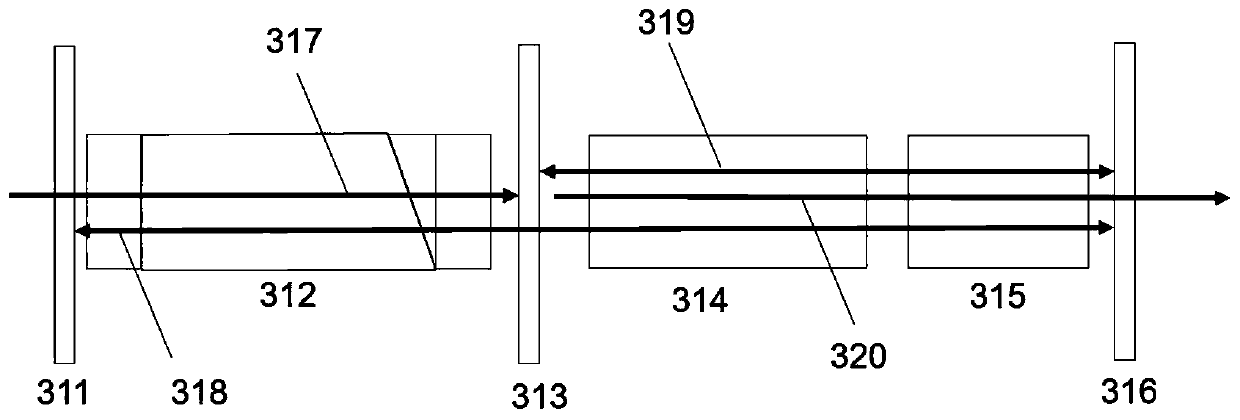

[0027] see Figure 1-5 1. A novel solid-state laser, comprising: a pumping system, a laser system 3, an air cooling system for cooling the laser system 3 and the pumping system; the pumping system and the laser system 3 are arranged in a metal casing, and the Said laser system 3 is also individually packaged by a packaging case, said pumping system includes a driving power supply, a semiconductor laser pumping array 2 and a focusing lens group 302; said driving power drives the semiconductor laser pumping array 2 to emit pumping light 317, The pump light 317 is input into the laser system 3 through the focusing lens group 302, and the laser system 3 includes: an input mirror module 303, a bonded crystal module 304, an intermediate mirror module 305, a nonlinear crystal module 306 and an output mirror module 307; the input mirror module 303, the bonded crystal module 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com