Praseodymium-gadolinium co-doped mixed calcium fluoride laser crystal and preparation method and application thereof

A technology of laser crystals and calcium fluoride, applied in chemical instruments and methods, lasers, crystal growth, etc., can solve problems such as difficult to achieve all-solid-state fs ultrafast visible light laser output, fluorescence spectrum width, etc., to achieve easy growth and repeatability High performance and large size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

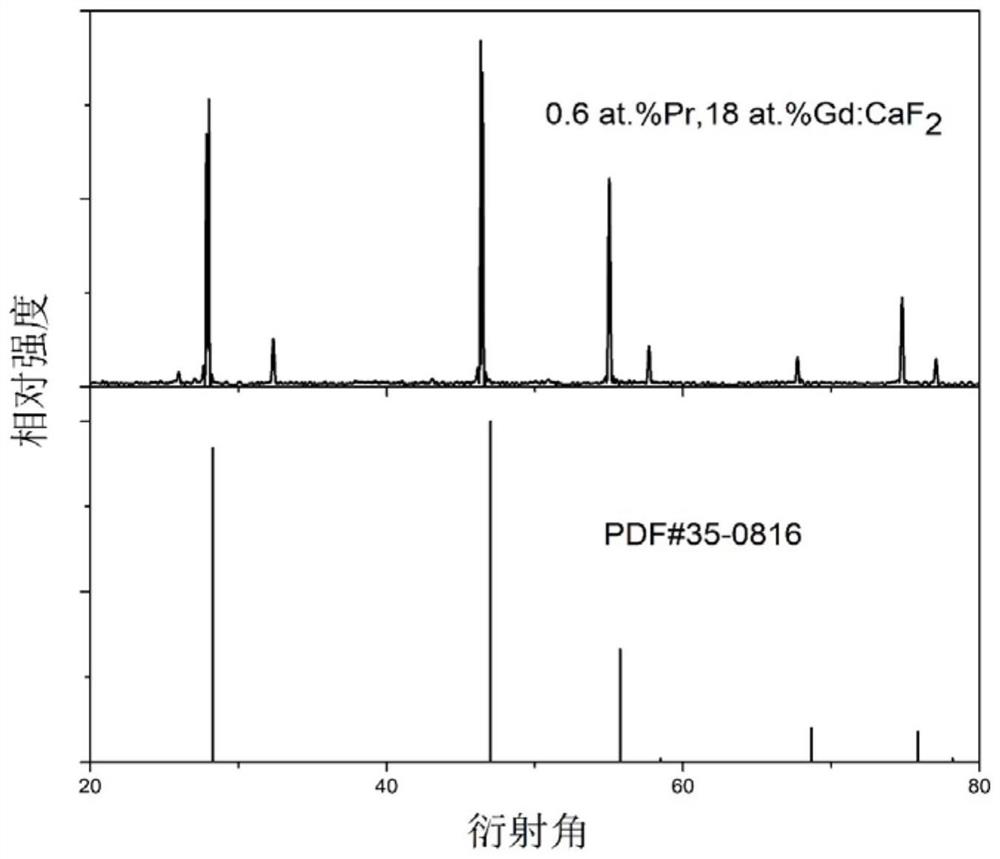

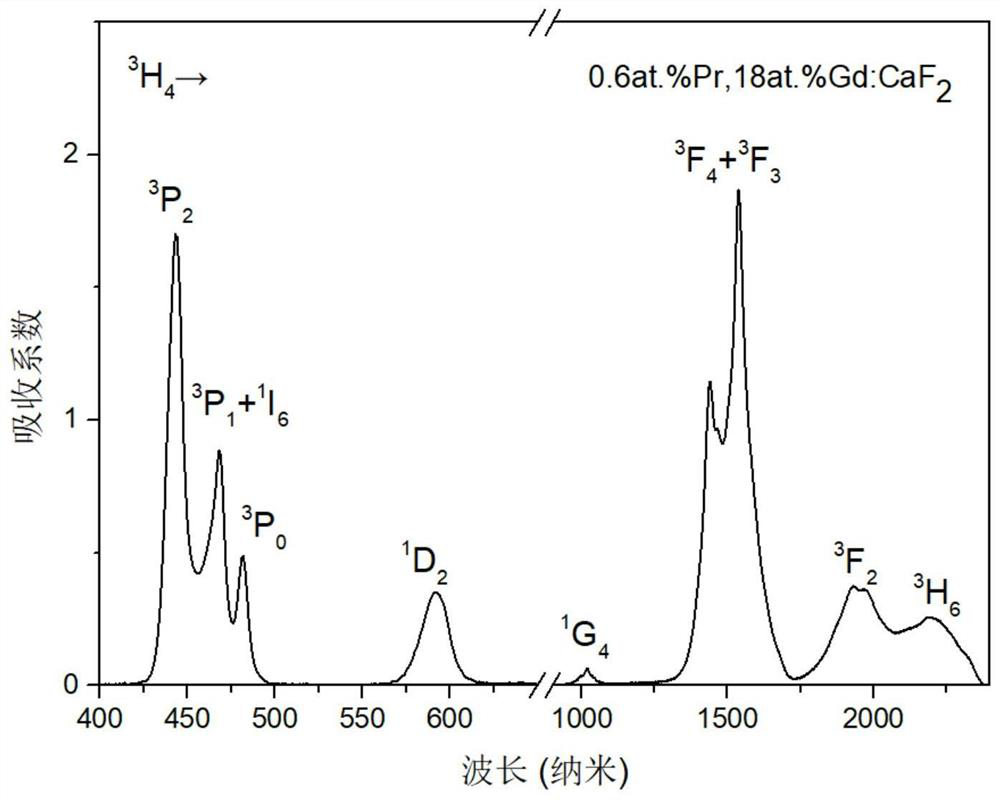

[0033] Growth of Pr by temperature gradient method 0.006 Gd 0.18 Ca 0.82 f 2.186 , specifically prepared by the following method:

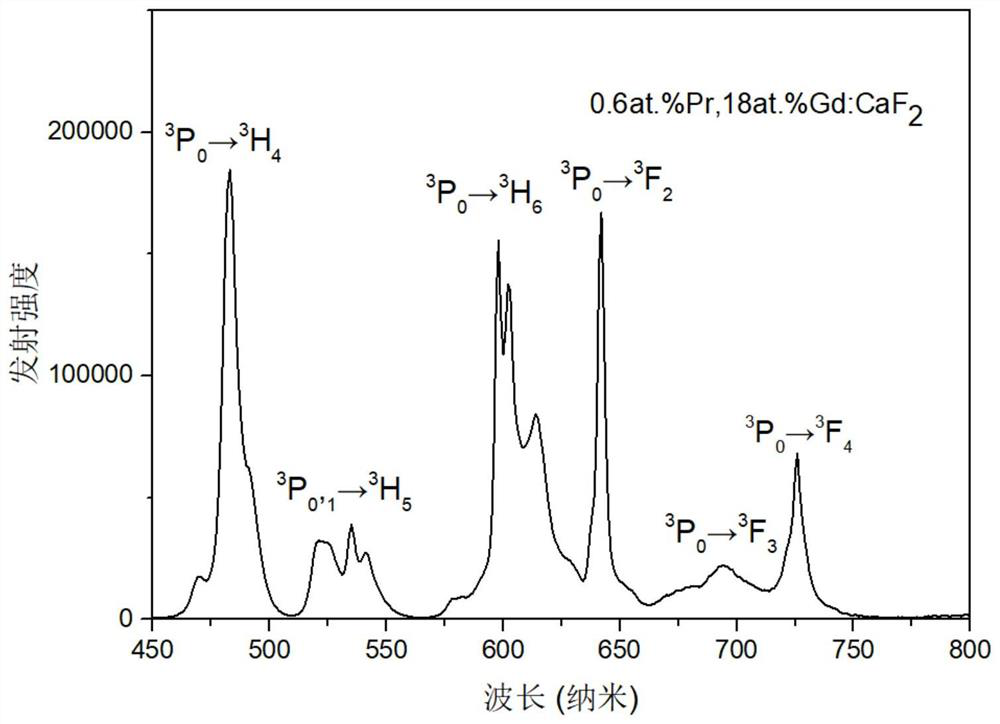

[0034] Growth of Pr by temperature gradient method 0.006 Gd 0.18 Ca 0.82 f 2.186 Crystal, put 35g of raw material in a graphite crucible, vacuumize the furnace, fill in high-purity argon as a protective atmosphere, raise the temperature to 1430°C at a rate of 300°C / h, keep the temperature for 4 hours until the raw material is completely melted, and use 1°C / h h cooling rate growth, the growth time is 120h. The crystals were taken out after the growth was finished and the temperature was slowly lowered. Obtain a piece of Pr with good optical quality 0.006 Gd 0.18 Ca 0.82 f 2.186 Crystals whose emission cross sections at 642 nm are of the order of 10 -19 cm, 16.4×10 –20 cm 2 , the fluorescence lifetime is 37.45, and the spectral quality factor is 614.18×10 -20 cm2 ·μs, the full width at half maximum is 3.67nm, and the quality factor o...

Embodiment 2

[0040] Growth of Pr by temperature gradient method 0.006 Gd 0.1 Ca 0.9 f 2.106 Specifically prepared by the following methods:

[0041] Growth of Pr by temperature gradient descent method 0.006 Gd 0.1 Ca 0.9 f 2.106 Crystal, starting from PrF of 5N purity 3 , GdF 3 and CaF 2 single crystal particles. After Pr ions and Gd ions are doped to replace Ca ions, according to the chemical formula Pr 0.006 Gd 0.1 Ca 0.9 f 2.106 Calculate the mass required for each raw material and weigh it accurately, put the weighed raw material into a graphite crucible, vacuumize the furnace, fill in high-purity argon as a protective atmosphere, and heat up to 1430 °C at a rate of 300 °C / h ℃, keep the temperature for 4 hours until the raw materials are completely melted, grow at a cooling rate of 1 ℃ / h, and the growth time is 120h. The crystals were taken out after the growth was finished and the temperature was slowly lowered. Obtain a piece of Pr with good optical quality 0.006 Gd ...

Embodiment 3

[0043] Growth of Pr by temperature gradient method 0.006 Gd 0.28 Ca 0.78 f 2.286 Specifically prepared by the following methods:

[0044] Growth of Pr by temperature gradient method 0.006 Gd 0.28 Ca 0.78 f 2.286 Crystal, starting from PrF of 5N purity 3 , GdF 3 and CaF 2 single crystal particles. After Pr ions and Gd ions are doped to replace Ca ions, according to the chemical formula Pr 0.006 Gd 0.28 Ca 0.78 f 2.286 Calculate the mass required for each raw material and weigh it accurately, put the weighed raw material into a graphite crucible, vacuumize the furnace, fill in high-purity argon as a protective atmosphere, and heat up to 1430 °C at a rate of 300 °C / h ℃, keep the temperature for 4 hours until the raw materials are completely melted, grow at a cooling rate of 1 ℃ / h, and the growth time is 120h. The crystals were taken out after the growth was finished and the temperature was slowly lowered. Obtain a piece of Pr with good optical quality 0.006 Gd 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com