Yb: YAG (yttrium aluminum garnet) and Cr, Yb: YAG self-Q-switching laser

A technology of yttrium aluminum garnet and garnet, which is applied in the field of lasers, can solve the problems of unfavorable access to high-efficiency integrated miniaturized high-peak power solid-state lasers, no practical application prospects, and low work efficiency, so as to achieve high peak power and improve reflection Number of revolutions, efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

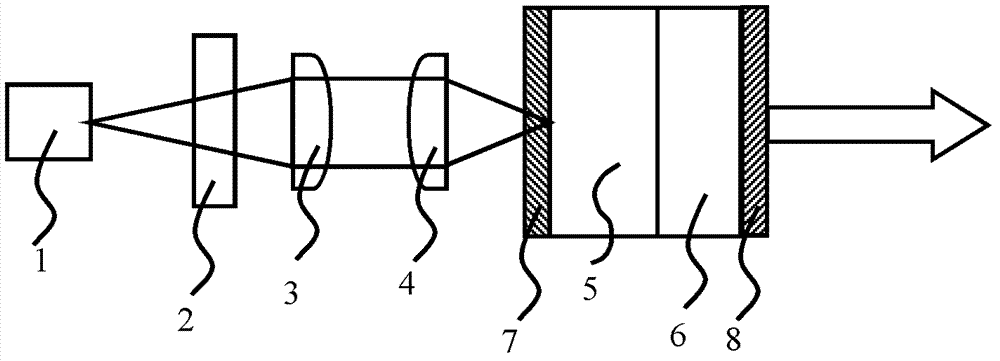

[0014] see figure 1 , the embodiment of the present invention is provided with pumping source 1, isolator 2, the 1st lenticular lens 3, the 2nd lenticular lens 4, laser increment medium Yb:YAG crystal 5 and Cr, Yb:YAG crystal 6; Said pumping Source 1, isolator 2, the first lenticular lens 3, the second lenticular lens 4, laser increment medium Yb:YAG crystal 5 and Cr, Yb:YAG crystal 6 are arranged in sequence from front to back and are located on the same optical axis, the Laser increment medium Yb: the rear surface of YAG crystal 5 is plated with anti-reflection film and high reflection film 7 as the rear cavity mirror of laser cavity, and the front surface of said Cr, Yb: YAG crystal 6 is plated with anti-reflection film and reflective film 8 as The front cavity mirror of the laser cavity.

[0015] The pump source 1 is a 940nm laser diode, the ant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com