Straw drainage piece

A drainage body and straw technology, applied in soil drainage, construction, application, etc., can solve the problems of easy pollution, difficult construction, heavy weight, etc., and achieve the effect of no pollution to the environment, low price, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

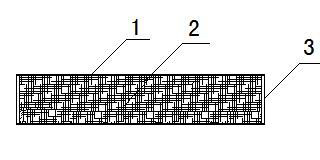

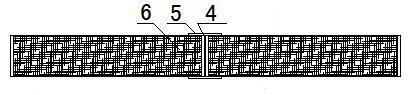

[0010] With reference to the accompanying drawings, the structure of the straw drainage body is as follows: a straw section 2 is arranged in a non-woven bag 1, and binding straps 3 are arranged at both ends of the non-woven bag to make the non-woven bag solid. Said straw section 2 is 30-50mm. The specific method of the above-mentioned straw drainage body is: a、 Cut the cotton stalks into straw section 2, the section length is: 30-50mm; b. Soak in antiseptic solution for 3-10 days, remove and wait for solidification to dry; c. Put straw section 2 into non-woven bag 1 Medium, compacted to a certain degree of compactness, use Density Control porosity, thereby controlling water permeability. Non-woven fabrics are selected according to the requirements of water permeability thickness . The length of the non-woven bag is customized according to the construction requirements.

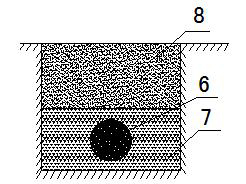

[0011] When constructing the drainage ditch, the specific method is: in the excavated drainage ditch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com