Boat-shaped blade vertical axis wind turbine generator

A wind turbine, vertical shaft technology, applied to wind turbines, wind motor combinations, wind turbines at right angles to the wind direction, etc., can solve problems such as high maintenance costs, non-competitive, low fan power, etc., to achieve installation And the effect of reducing daily maintenance costs, improving wind energy utilization efficiency, and increasing stand-alone power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

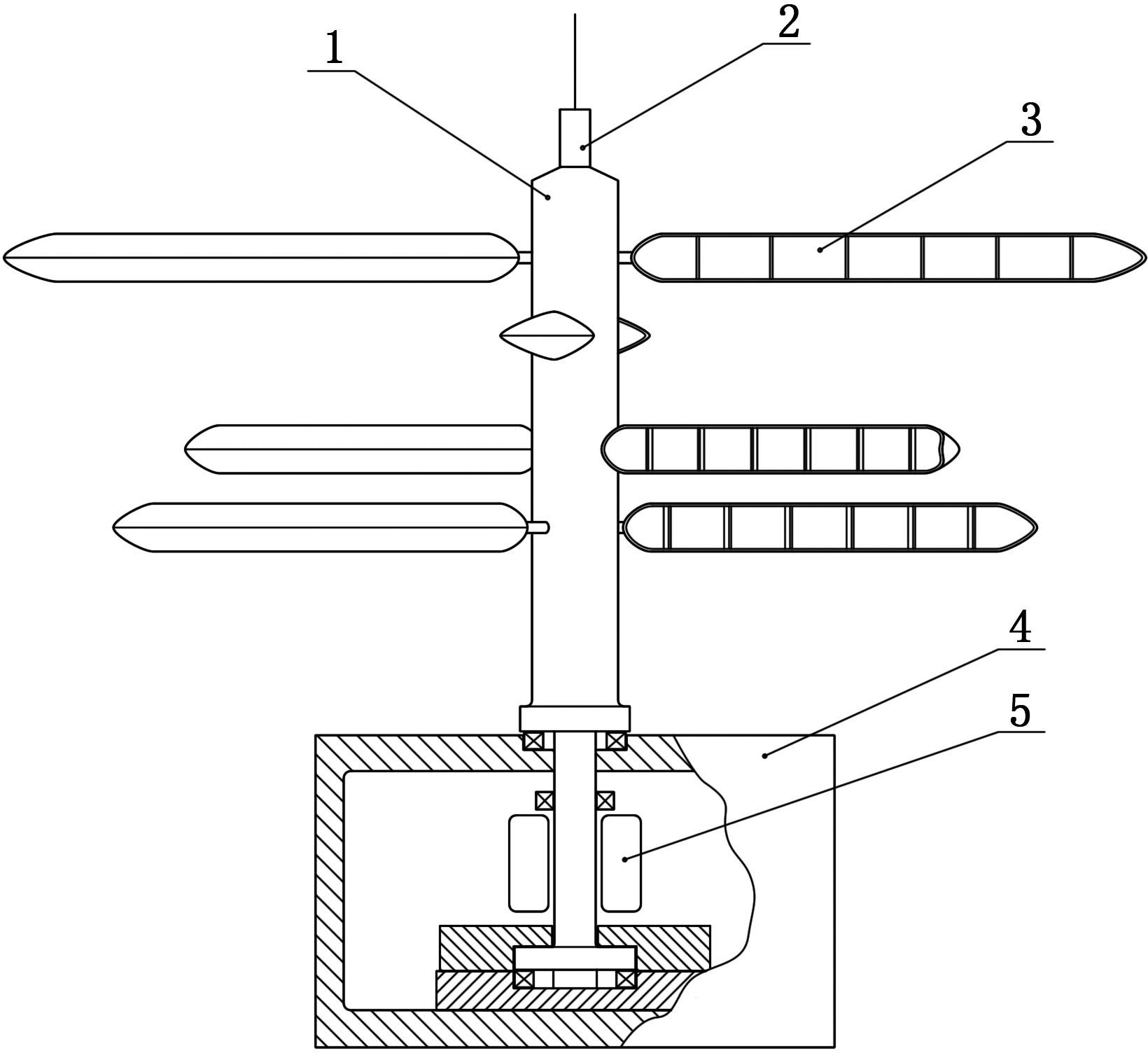

[0031] Depend on figure 1 —— Figure 5 It can be seen that the present invention includes a fan frame 4, a generator stator 5, and a generator rotor, and the generator stator 5 is installed in the fan frame 4; it also includes a main shaft 1, a stabilizing shaft 2 and four sets of blades horizontally installed on the main shaft 1 group; the stabilizing shaft 2 is assembled on the upper part of the main shaft 1; because the larger the main shaft 1 and the blades 3 of the wind turbine, the greater the lateral thrust of the wind force on the generator as a whole, the stabilizing shaft 2 is connected and fixed to the ground through a plurality of steel cables to play a role Stabilize the main shaft to resist the influence of lateral wind on the fan; the top of the stable shaft 2 is equipped with a lightning protection device and an anemometer;

[0032] The interior of main shaft 1 is a hollow structure, which is vertically assembled on fan frame 4. There are thrust bearings and g...

Embodiment 2

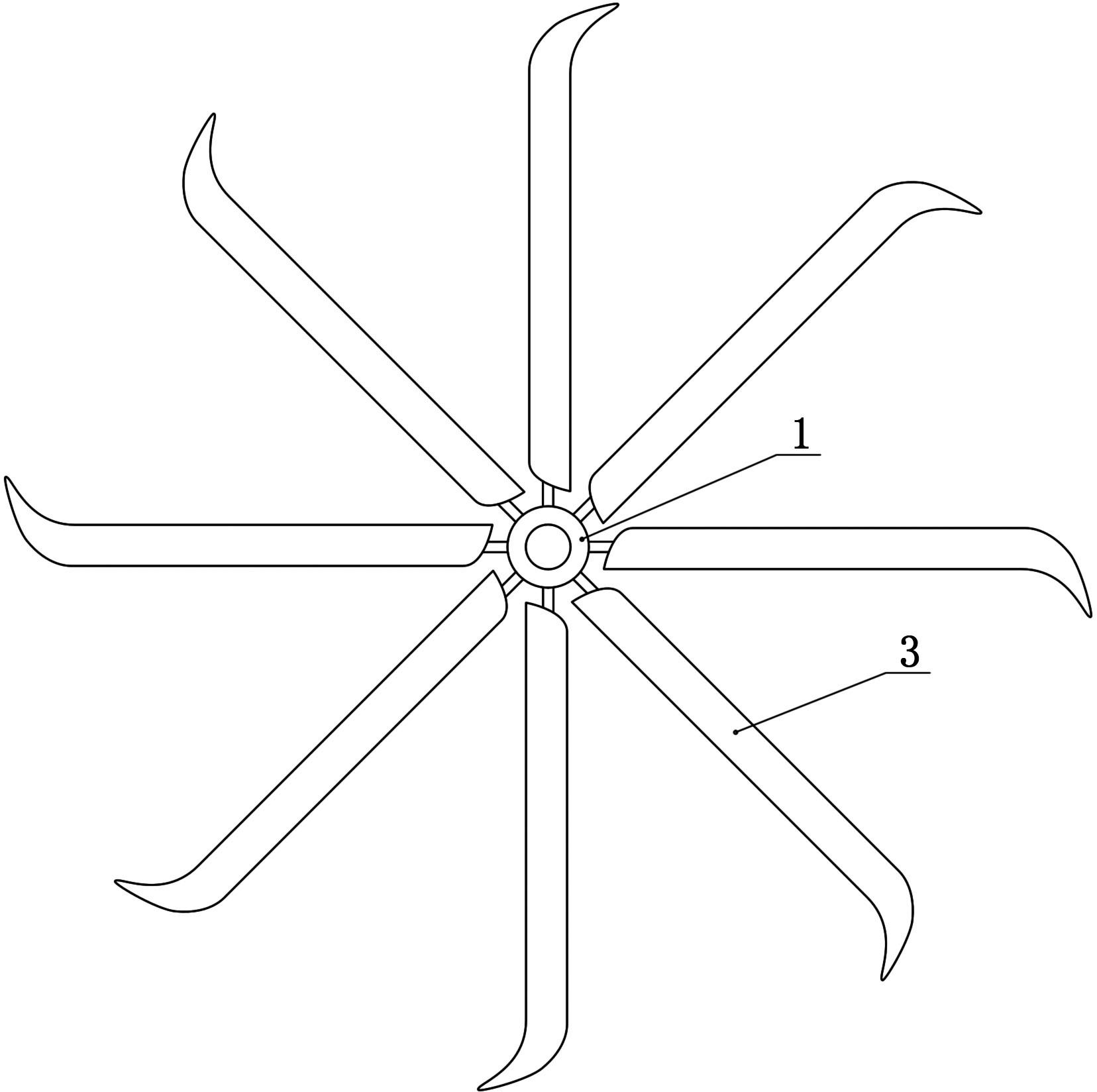

[0036] Depend on Figure 6 —— Figure 7 It can be seen that the difference between this embodiment and Embodiment 1 is that according to the needs of output power, 12 groups of blade groups are fixed on the main shaft of this embodiment; the cross-section of the blades 3 is an isosceles triangle; the assembly of each group of blade groups is : The projections of the first group and the second group of blade groups in the horizontal plane are perpendicular to each other; the projections of the third group and the fourth group of blade groups in the horizontal plane are mutually perpendicular; the projections of the third group and the first group of blade groups in the horizontal plane are The included angle is 45 degrees; the fifth-eighth group and the ninth-twelfth group of blade groups repeat the arrangement of the first-fourth group; the projection of all blades in the horizontal plane is 45°.

[0037] Other structures of this embodiment are the same as those of Embodiment...

Embodiment 3

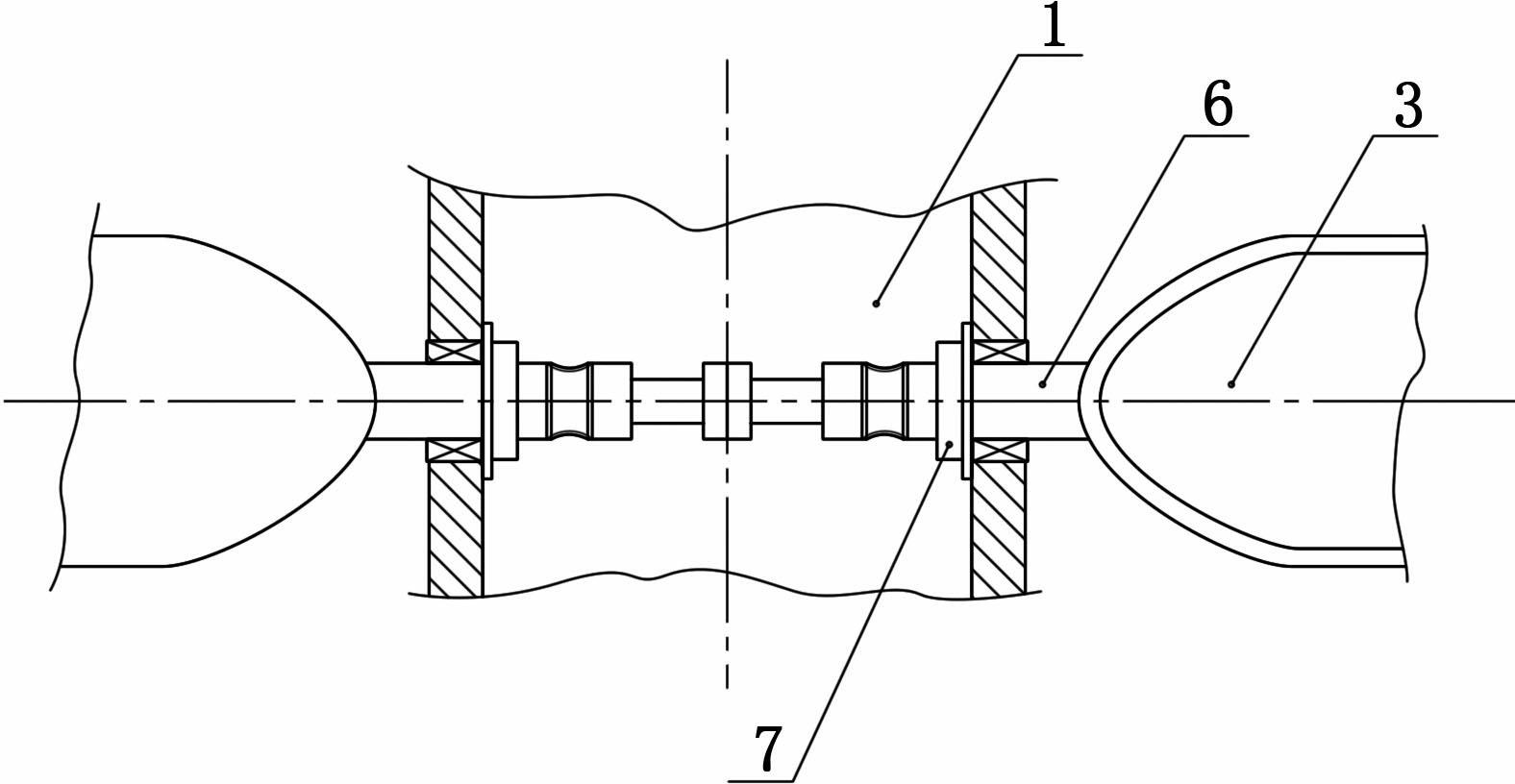

[0039] Depend on Figure 7 —— Figure 9 It can be seen that the difference between this embodiment and Embodiment 1 is that the form of the blade group is that each group of blade groups is composed of three boat-shaped blades 3 and shaft arms 6, and the tail end of the shaft arms 6 is provided with a tapered The gear, the tail end of the shaft arm 6 is inserted into the main shaft 1 and is limited by the chuck 7 fixed on the shaft arm 6, and is positioned by the fixed sleeve 9 fixed on the inner wall of the main shaft; the inside of the main shaft 1 is coaxially equipped with an adjustment rod 8, The adjusting rod 8 is provided with a plurality of bevel gears, which are respectively engaged with the bevel gears at the tail ends of the shaft arms 6 of each blade group; the other end of the adjusting rod 8 is connected to the control motor; the three blades 3 of the blade group are on the same horizontal plane 120° within each other; the projections of the upper and lower adja...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com