Plunger type motor pump

A motor pump and plunger technology, applied in the field of plunger pumps, can solve the problems of low overall power density and weak cylinder strength, and achieve the effects of improving the utilization rate of internal space, large structural design, and improving strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

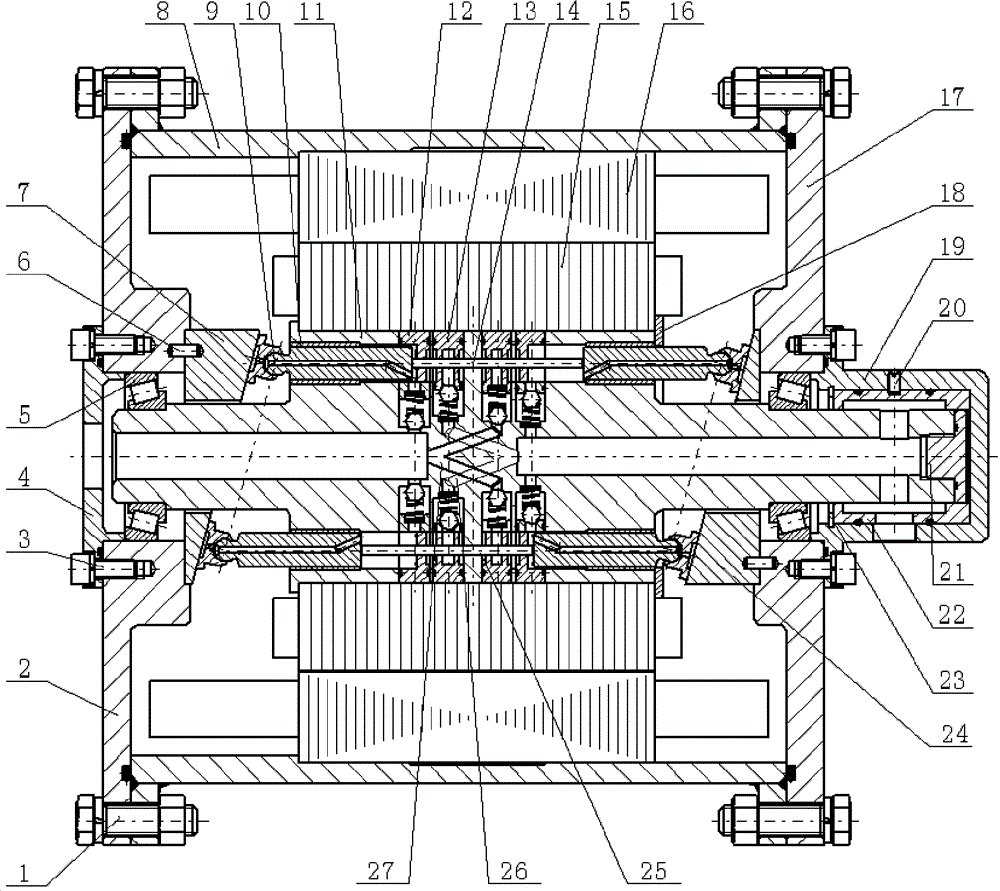

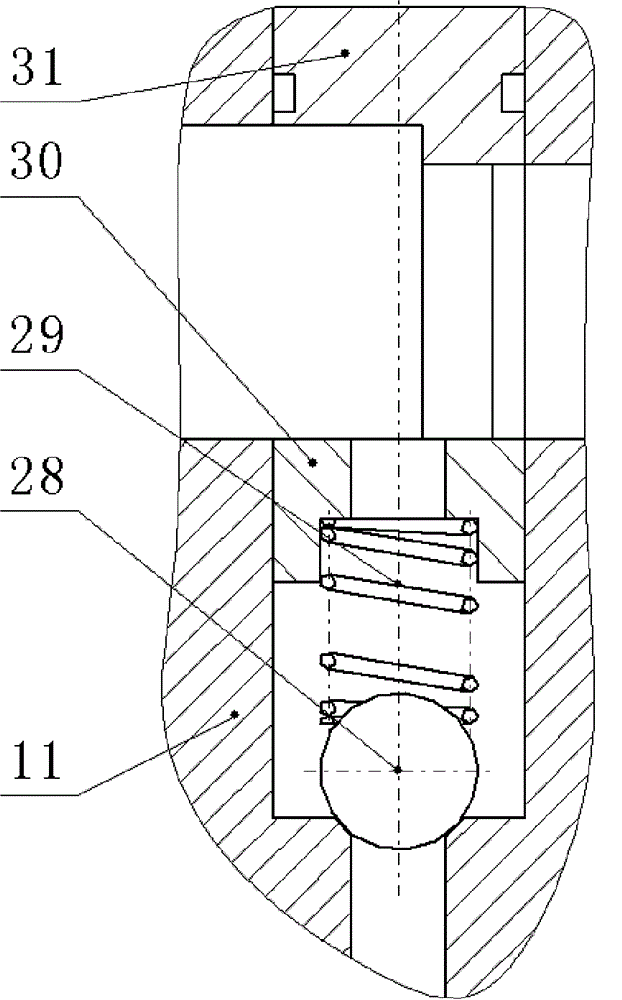

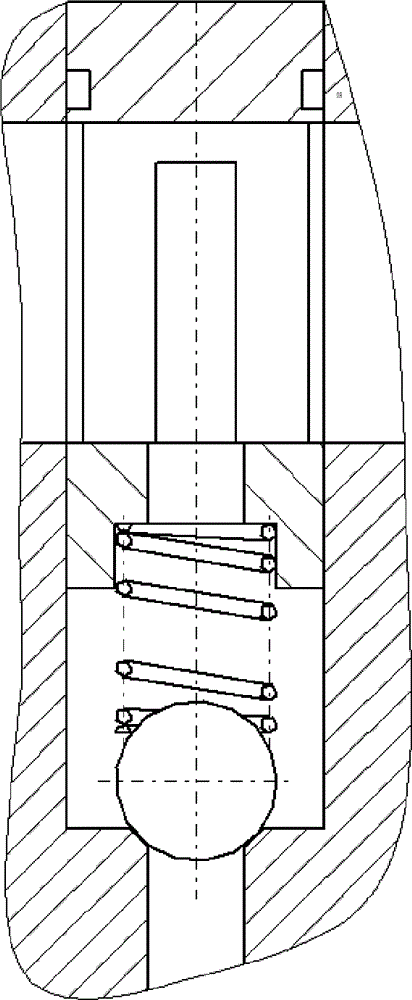

[0032] Such as figure 1 As shown, the embodiment of the present invention includes a casing 8, a motor stator 16, a motor rotor 15, a cylinder block 11, 10 plunger shoe assemblies 9, a left swash plate 7, a right swash plate 24, and 10 suction valve assemblies 12 and 10 A extrusion valve assembly 13, the casing 8, the motor stator 16 and the motor rotor 15 are all cylindrical, the motor stator 16 is assembled in the casing 8, and the left end cover 2 and the right end cover 17 are respectively fixed to the casing by bolts 1 8. At the left and right ends, the cylinder body 11 is a stepped shaft with a central boss, and its two ends are respectively supported by the tapered roller bearings 5 at the center of the left end cover 2 and the center of the right end cover 17, and the left bearing cover 4 is fastened by screws 3 In the center of the left end co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com