Water cycle cooling device for automobile brake drums

A technology of automobile braking and cooling devices, which is applied to brake drums, slack adjusters, etc., and can solve problems such as brake failure and temperature rise of brake drums

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

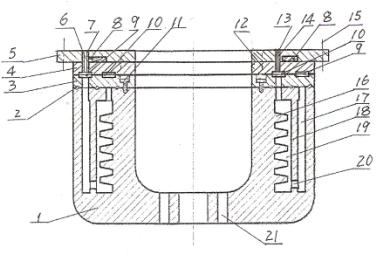

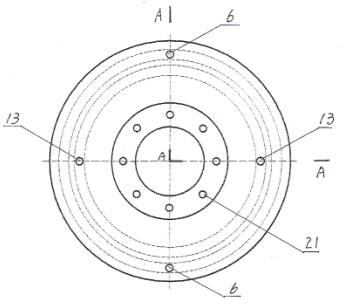

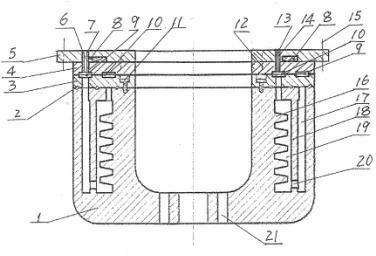

[0014] A cooling cavity is provided in the wall of the brake drum (1), and a fixed partition (18) is formed in the middle of the cooling cavity. The partition divides the cooling cavity into a water inlet cooling cavity (17) and a water outlet cooling cavity (19). ), there are 8-20 water passage holes (20) at the bottom of the partition, so that the inlet and outlet cooling chambers communicate with each other; the diameter of the water passage holes is 5-10 mm, and the outlet cooling chamber is provided with 2-4 heads clockwise. Rotating spiral fins (16). The stationary ring (4) is made of wear-resistant metal material, the outer diameter of the stationary ring is the same as the outer diameter of the brake drum, the inner diameter is the same as the inner diameter of the brake drum, and the thickness is 10-20 mm. The moving ring (3) is made of graphite with self-lubricating and wear-resistant properties, or ceramic or metal with self-lubricating and wear-resistant properties...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com