Multi-beam parallel laser direct writing device and method

A laser direct writing and multi-beam technology, which is applied in photolithographic exposure devices, microlithography exposure equipment, optics, etc., can solve the problem of unstable laser light source energy during processing, and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

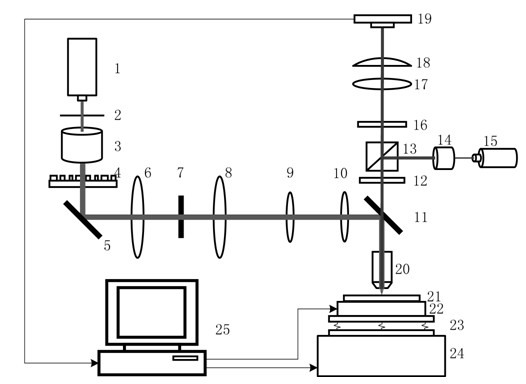

[0032] The present invention will be further described below in conjunction with the specific application of the manufacturing process and the accompanying drawings, but the application of the present invention is not limited thereto.

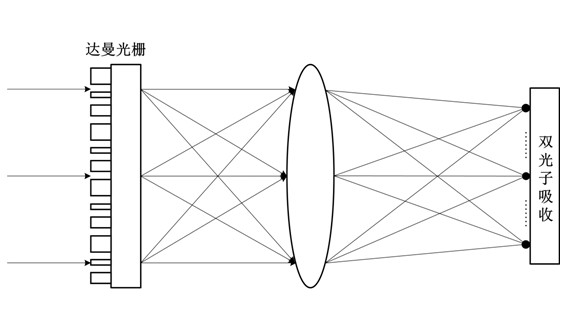

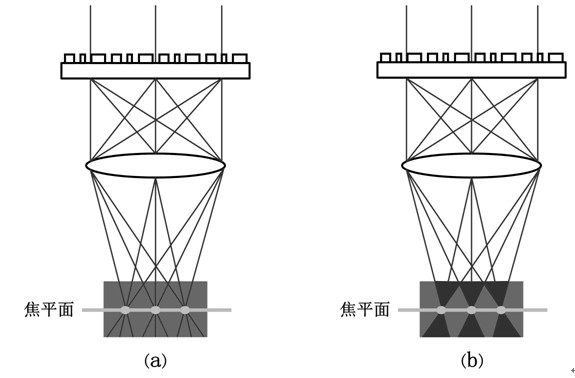

[0033] see first image 3 , image 3It is the optical path structure diagram of the multi-beam parallel laser direct writing device of the present invention. It can be seen from the figure that the multi-beam parallel laser direct writing device of the present invention includes a writing optical path, a detection optical path, a three-dimensional moving mechanism and a computer, and its characteristics are:

[0034] The writing optical path includes a femtosecond laser 1, and along the laser output advancing direction of the femtosecond laser 1, there are successively an aperture stop 2, a beam expander lens group 3, a Damman grating 4, a first beam expander lens 6, a gradient Refractive index filter 7, second beam expander lens 8, transfer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com