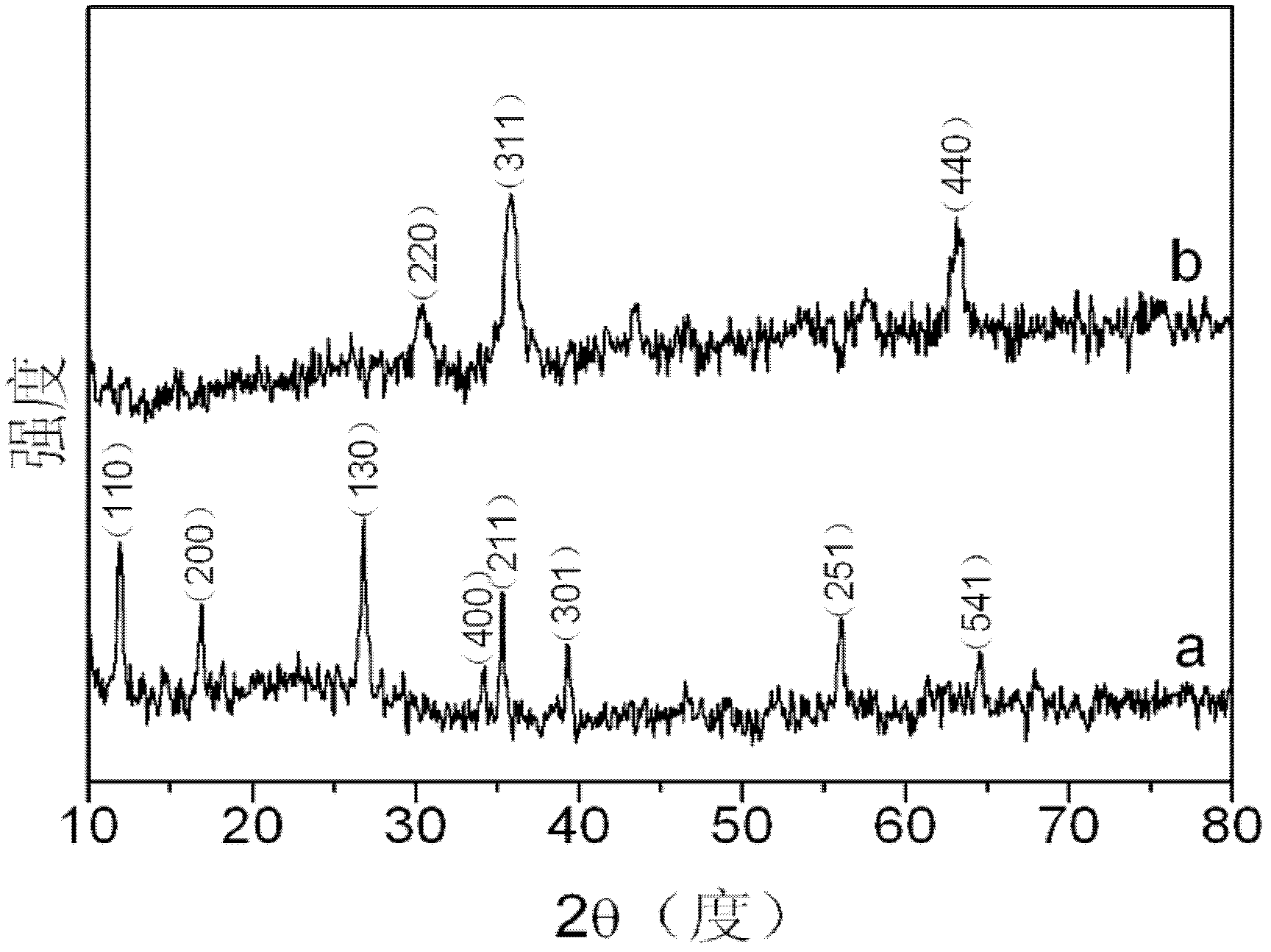

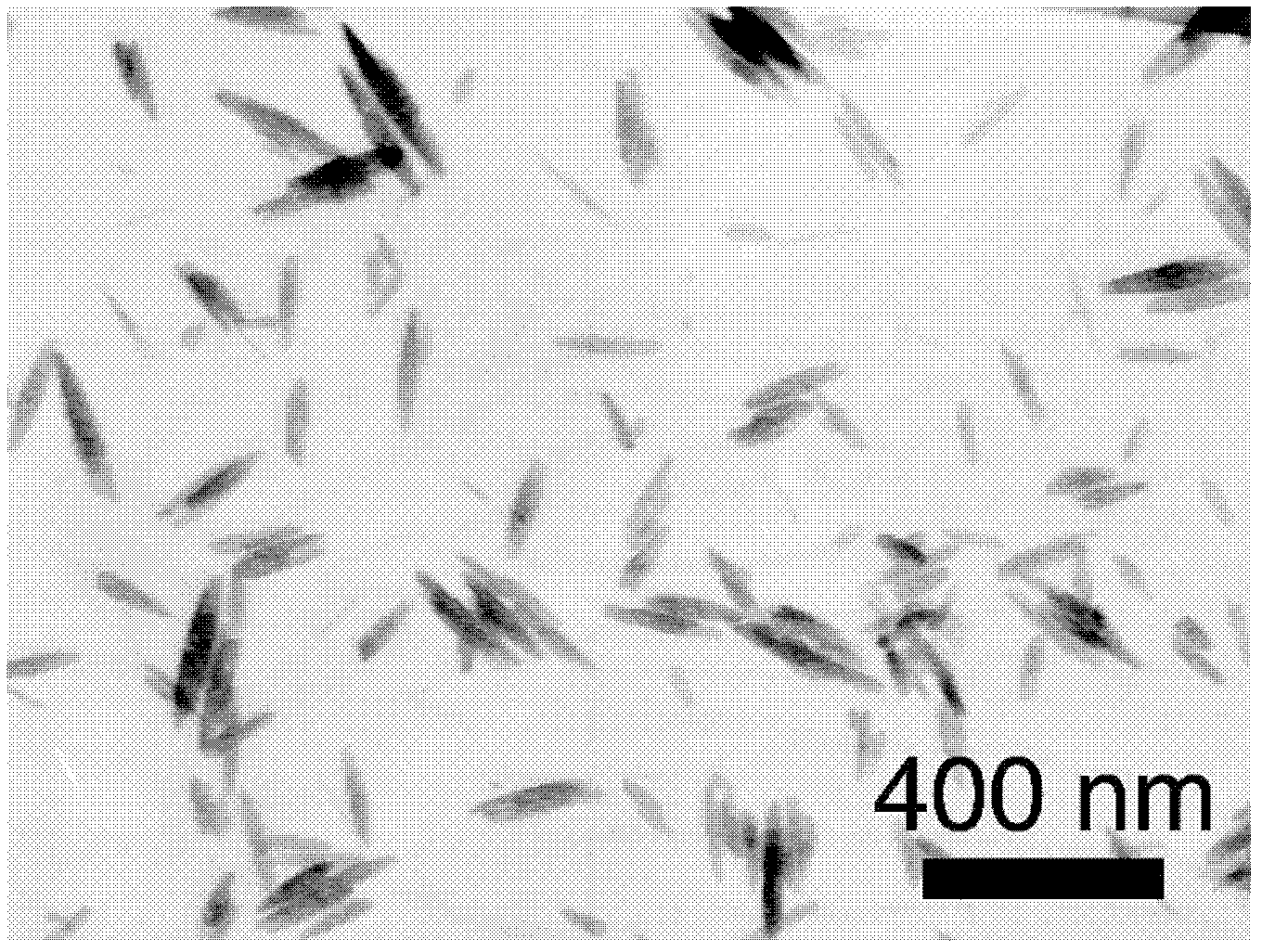

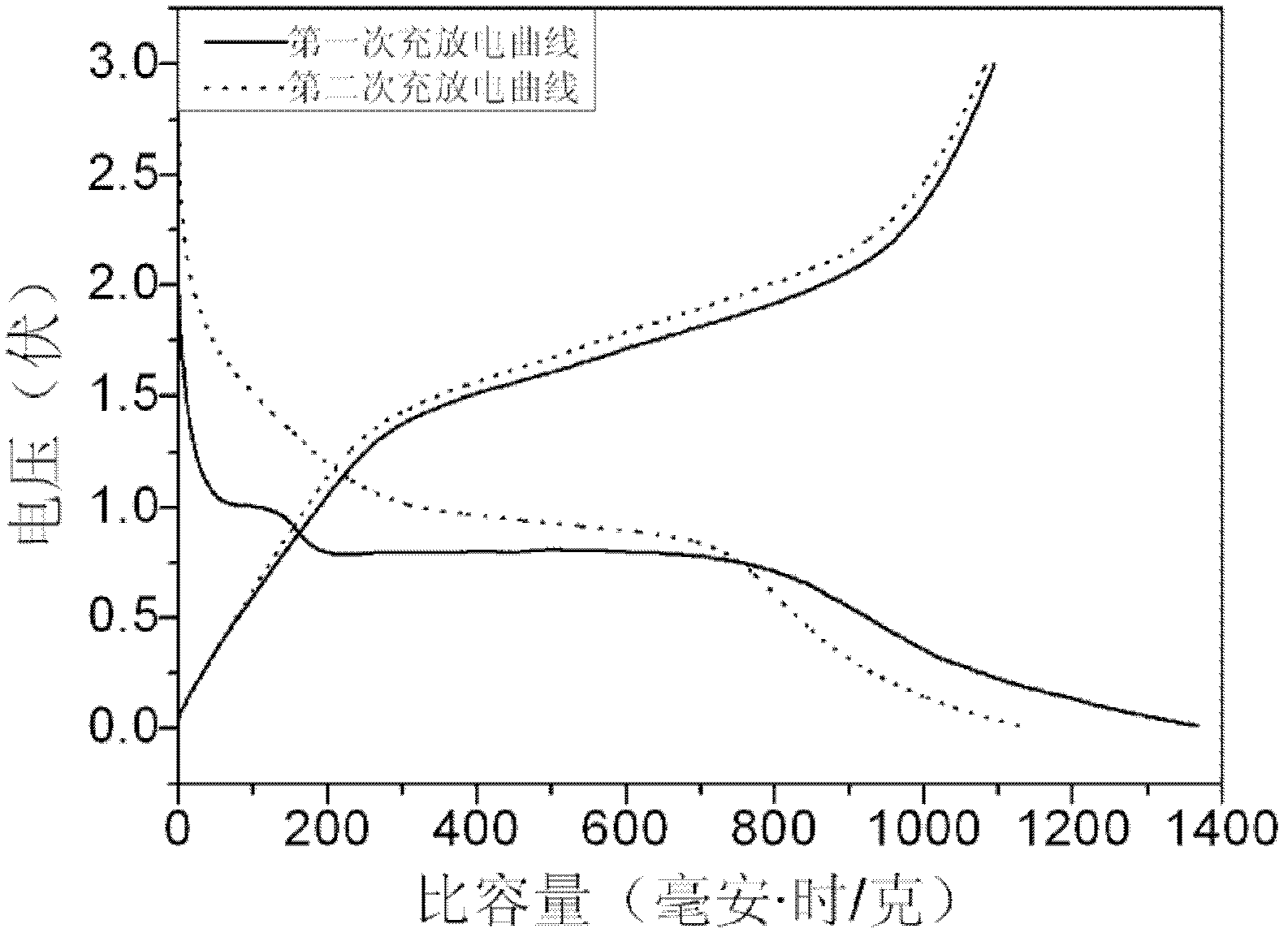

High specific capacity spindle-shaped ferroferric oxide/carbon nano composite material for negative electrode of lithium ion battery

A technology of triiron tetroxide and lithium ion batteries, which is applied in battery electrodes, circuits, electrical components, etc., to achieve the effects of simple and easy operation, low price, and overcoming low Coulomb efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] (1) Mix glycerol and distilled water in a volume ratio of 1:4 as a solvent, add soluble iron salt to the solvent in a ratio of 3 mmol: 40 mL, and stir magnetically for 25 minutes to make the iron salt completely dissolved;

[0031] (2) Transfer the solution prepared in step (1) to a reaction kettle with a polytetrafluoroethylene liner, and place it in an oven at 120° C. for 12 hours;

[0032] (3) The reaction kettle is naturally cooled to room temperature, then the product is separated by suction filtration, washed 5 times with distilled water and absolute ethanol respectively, and dried in an oven at 100° C. to obtain an orange-yellow ferric oxyhydroxide (FeOOH) solid that is Fusiform ferric oxyhydroxide precursor;

[0033] (4) According to the mass ratio of glucose and ferric oxyhydroxide being 5:1, weigh glucose and ferric oxyhydroxide prepared in step (3) respectively, ultrasonically disperse them in distilled water for 30min, and then transfer Put in a hydrother...

Embodiment 2

[0037] (1) Glycerol and distilled water are mixed as a solvent in a ratio of 1:3 by volume, and soluble iron salt is added to the solvent in a ratio of 7 mmol: 40 mL of soluble iron salt and solvent, and magnetically stirred for 25 minutes to make the iron salt completely dissolved;

[0038] (2) Transfer the solution prepared in step (1) to a reaction kettle with a polytetrafluoroethylene liner, and place it in an oven at 160° C. for 12 hours;

[0039] (3) The reaction kettle is naturally cooled to room temperature, then the product is separated by suction filtration, washed 5 times with distilled water and absolute ethanol respectively, and dried in an oven at 100° C. to obtain an orange-yellow ferric oxyhydroxide (FeOOH) solid that is Fusiform ferric oxyhydroxide precursor;

[0040] (4) According to the mass ratio of glucose and ferric oxyhydroxide being 7:1, weigh glucose and ferric oxyhydroxide prepared in step (3) respectively, ultrasonically disperse them in distilled ...

Embodiment 3

[0044] (1) Glycerol and distilled water are mixed in a ratio of 1:5 by volume as a solvent, and soluble iron salt is added to the solvent in a ratio of 5 mmol: 40 mL according to the ratio of soluble iron salt and solvent, and magnetically stirred for 25 minutes to make the iron salt completely dissolved;

[0045] (2) Transfer the solution prepared in step (1) to a reaction kettle with a polytetrafluoroethylene liner, and place it in an oven at 150° C. for 15 hours;

[0046] (3) The reaction kettle is naturally cooled to room temperature, then the product is separated by suction filtration, washed 5 times with distilled water and absolute ethanol respectively, and dried in an oven at 100° C. to obtain an orange-yellow ferric oxyhydroxide (FeOOH) solid that is Fusiform ferric oxyhydroxide precursor;

[0047] (4) According to the mass ratio of glucose and ferric oxyhydroxide being 8:1, weigh glucose and ferric oxyhydroxide prepared in step (3) respectively, ultrasonically disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com