Termination electrode device and preparation method for flow batteries

A liquid flow battery and manufacturing method technology, applied in the direction of fuel cell parts, indirect fuel cell, final product manufacturing, etc., can solve the problems of poor dimensional stability of terminal electrode plates, poor contact between terminals and current collector copper plates, etc., to achieve The effect of increasing conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

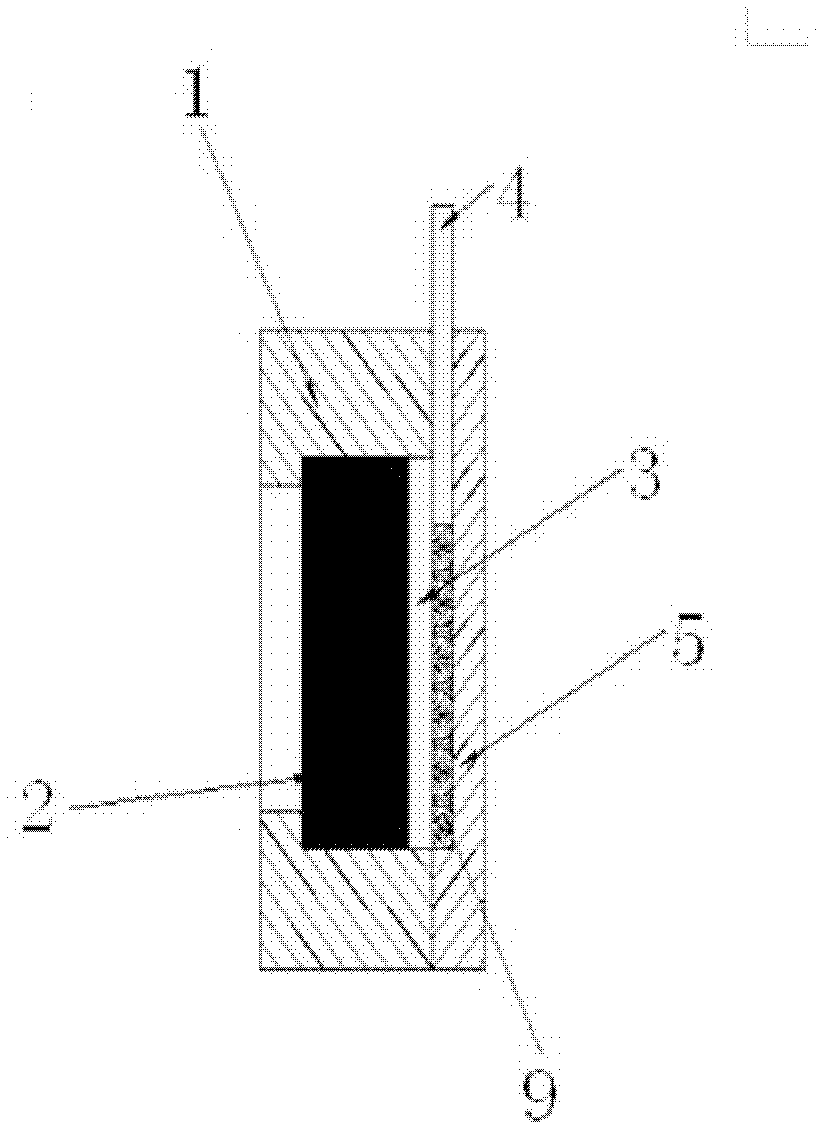

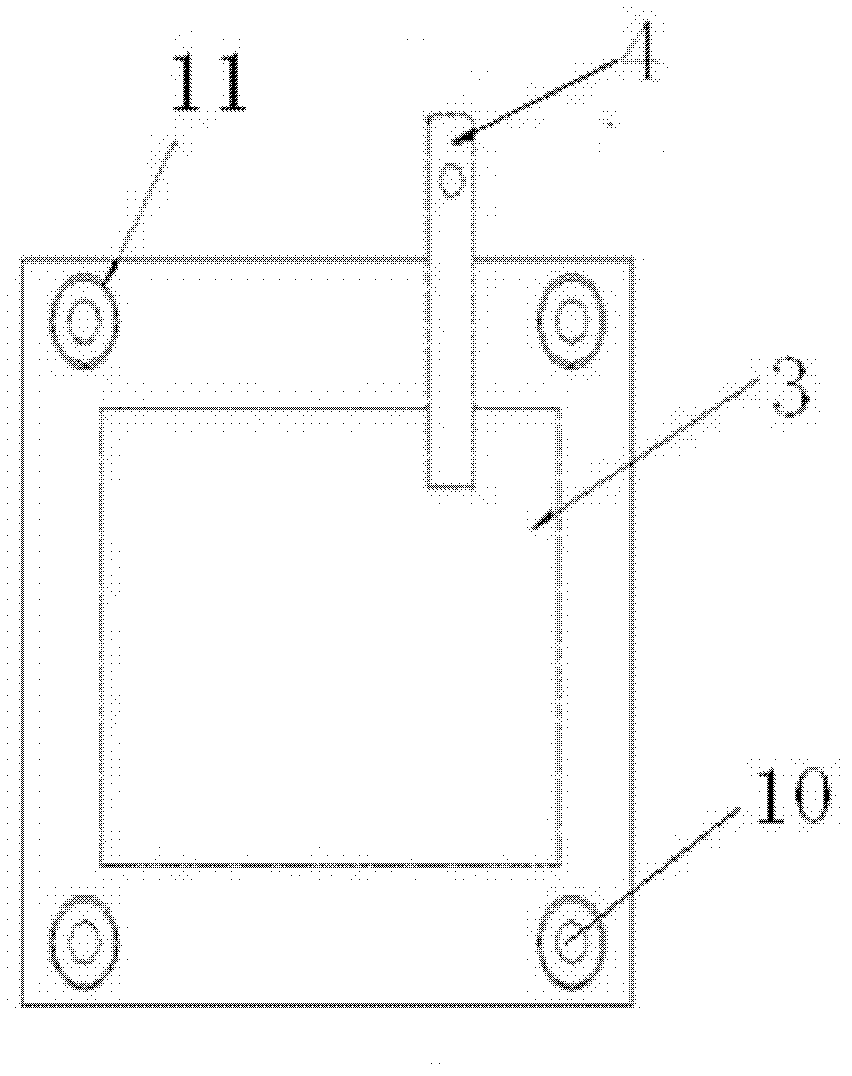

[0031] Embodiment 1 of the present invention: as Figure 1~3 As shown, a terminal electrode device for a liquid flow battery includes a terminal electrode frame 1 and a thickened terminal electrode 2, a rectangular hollow area is provided in the center of the terminal electrode frame 1, and the thickened terminal electrode 2 is fixed on the terminal electrode frame In the rectangular hollow area of 1, one side of the thickened terminal electrode 2 is provided with a current collector copper plate 3 fixedly connected thereto, the current collector copper plate 3 is provided with a terminal 4, and the current collector copper plate 3 is provided with one side of the terminal 4 An insulating plate 5 is provided, and the insulating plate 5 and the terminal electrode frame 1 are fixedly connected together by bolts.

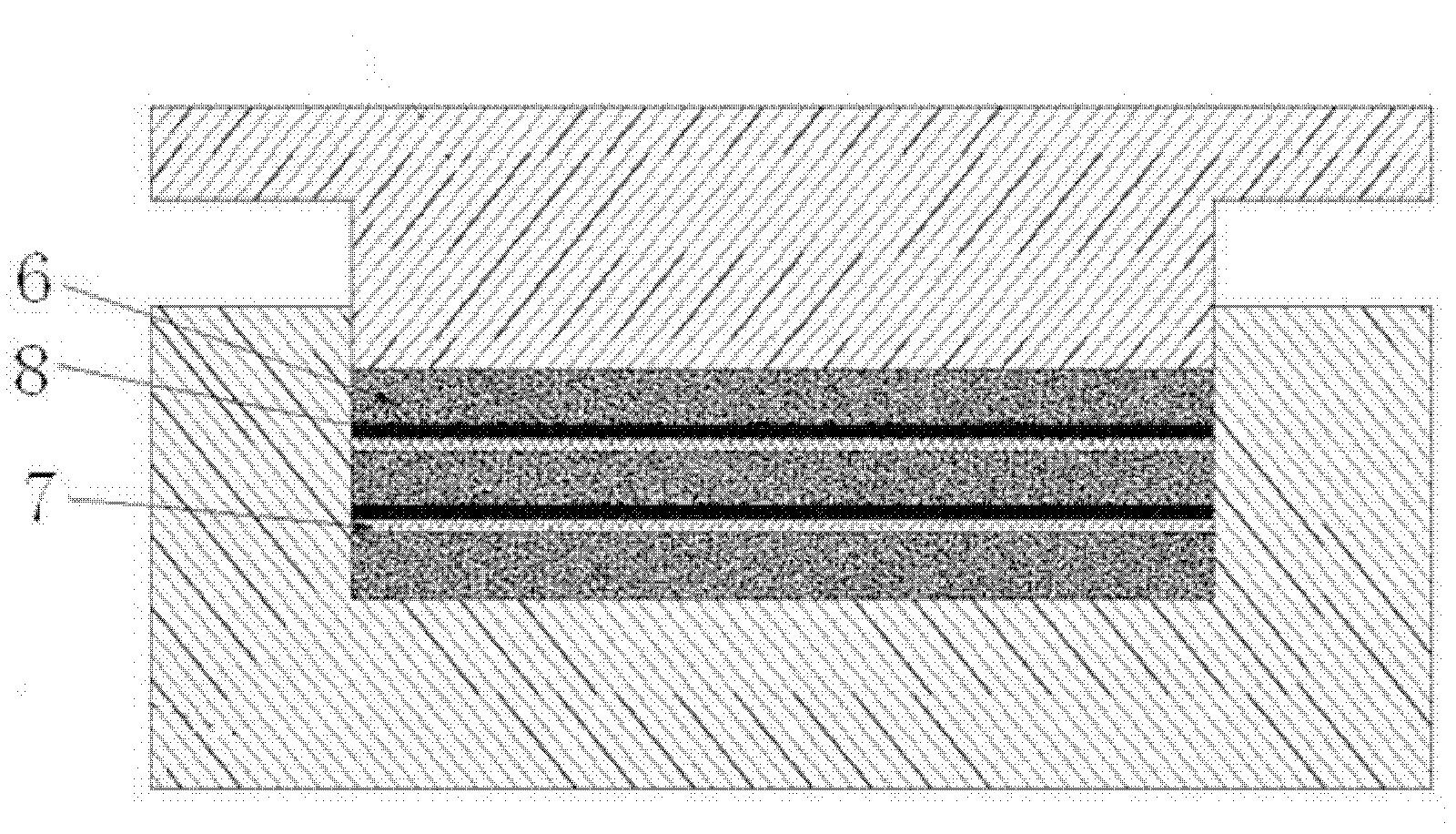

[0032] The thickened terminal electrode 2 is formed by stacking two layers of conductive plastic 6 , and a glass fiber layer 7 is arranged between two adjacent layer...

Embodiment 2

[0041] Embodiment 2 of the present invention: as Figure 1~3 As shown, a terminal electrode device for a liquid flow battery includes a terminal electrode frame 1 and a thickened terminal electrode 2, a rectangular hollow area is provided in the center of the terminal electrode frame 1, and the thickened terminal electrode 2 is fixed on the terminal electrode frame In the rectangular hollow area of 1, one side of the thickened terminal electrode 2 is provided with a current collector copper plate 3 fixedly connected thereto, the current collector copper plate 3 is provided with a terminal 4, and the current collector copper plate 3 is provided with one side of the terminal 4 An insulating plate 5 is provided, and the insulating plate 5 and the terminal electrode frame 1 are fixedly connected together by bolts.

[0042] The thickened terminal electrode 2 is formed by stacking three layers of conductive plastic 6 , and a glass fiber layer 7 is arranged between two adjacent lay...

Embodiment 3

[0051] Embodiment 3 of the present invention: as Figure 1~3 As shown, a terminal electrode device for a liquid flow battery includes a terminal electrode frame 1 and a thickened terminal electrode 2, a rectangular hollow area is provided in the center of the terminal electrode frame 1, and the thickened terminal electrode 2 is fixed on the terminal electrode frame In the rectangular hollow area of 1, one side of the thickened terminal electrode 2 is provided with a current collector copper plate 3 fixedly connected thereto, the current collector copper plate 3 is provided with a terminal 4, and the current collector copper plate 3 is provided with one side of the terminal 4 An insulating plate 5 is provided, and the insulating plate 5 and the terminal electrode frame 1 are fixedly connected together by bolts.

[0052] The thickened terminal electrode 2 is formed by stacking four layers of conductive plastic 6 , and a glass fiber layer 7 is arranged between two adjacent laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com