Compound control method of three-phase to two-phase orthogonal inverter power supply with reactive compensation function

A technology of inverter power supply and compound control, which is applied in reactive power compensation, reactive power adjustment/elimination/compensation, output power conversion devices, etc. problem, to achieve the effect of reducing reactive power compensation equipment and improving current waveform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

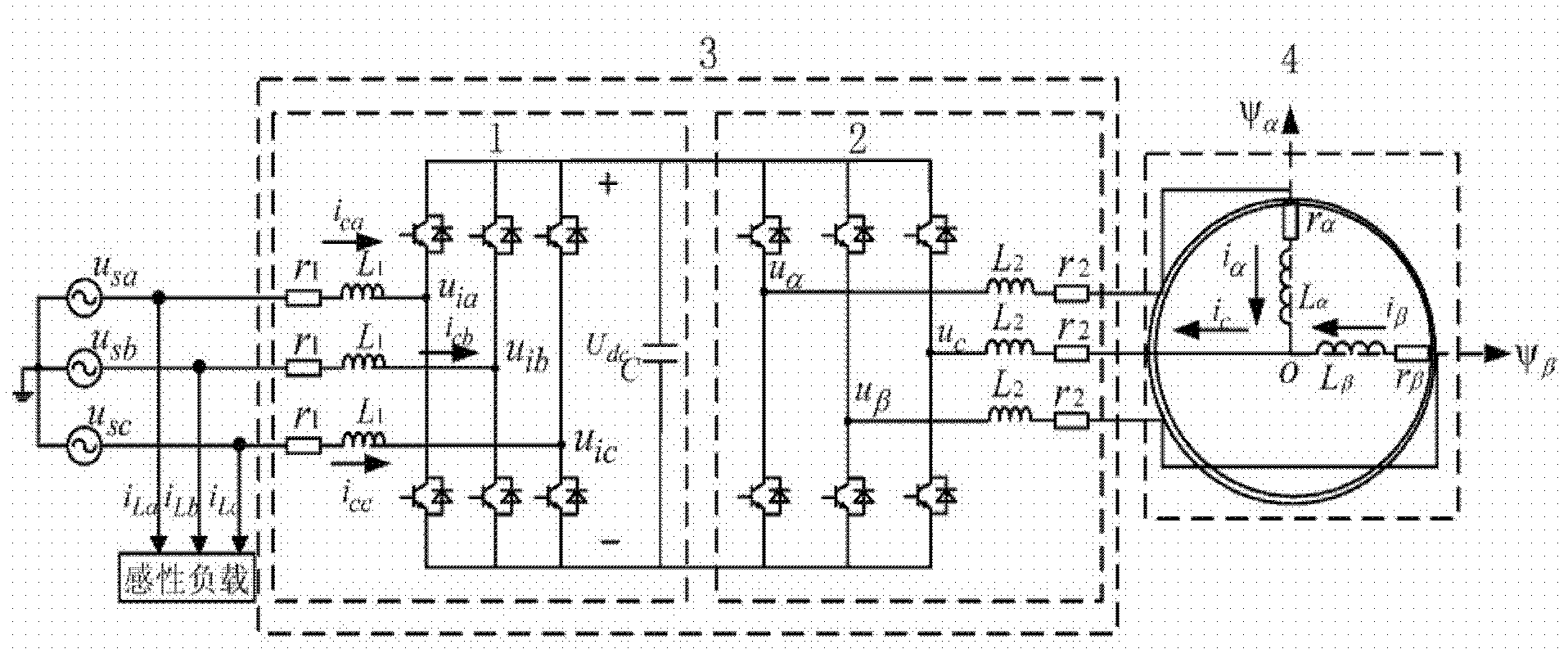

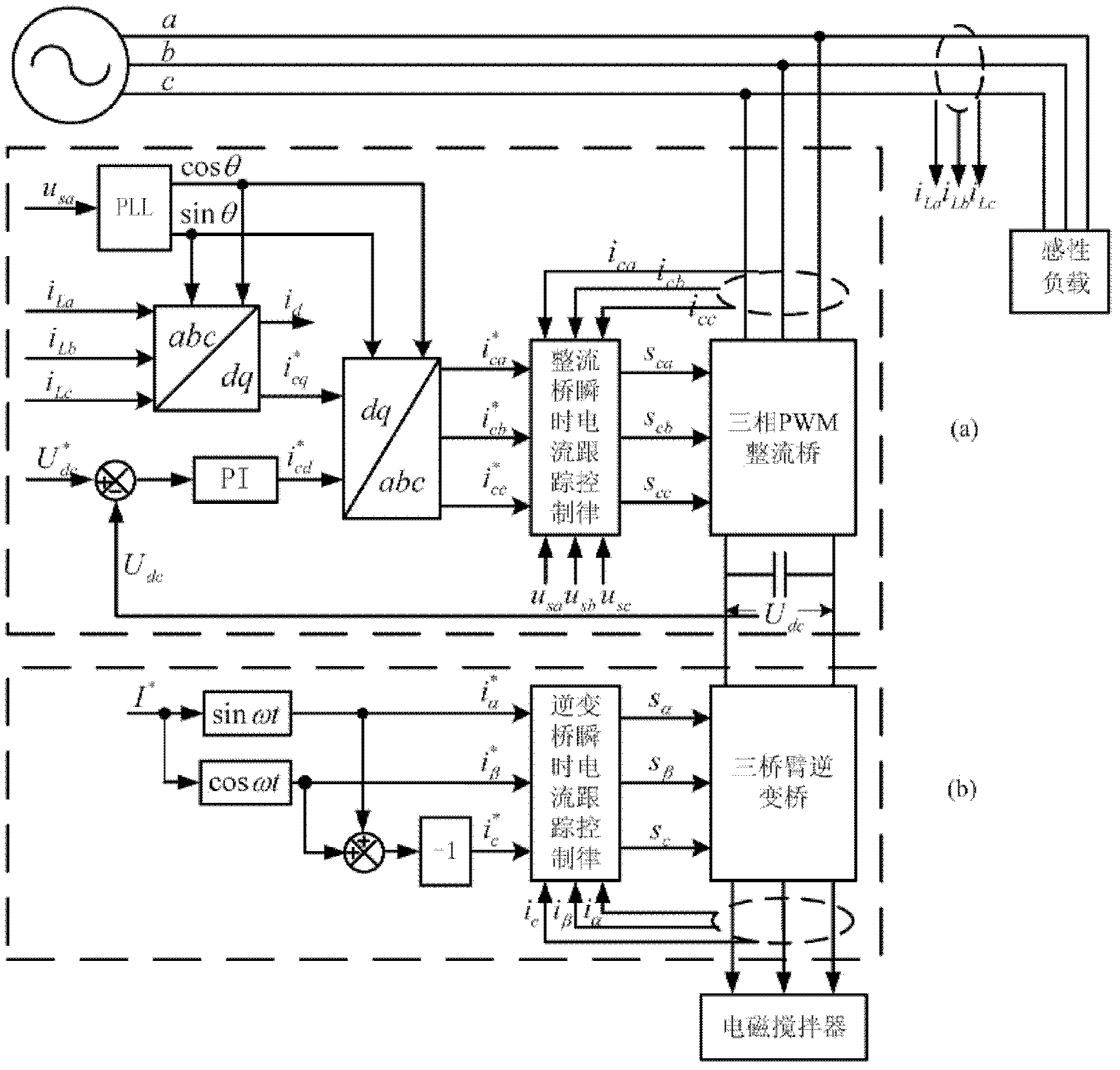

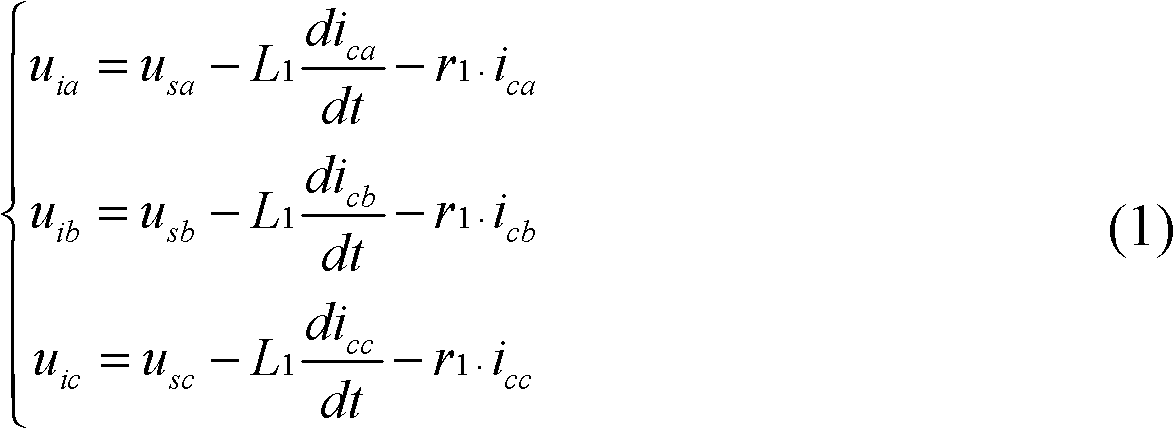

[0016] Such as figure 1 As shown, the main circuit of the three-phase to two-phase inverter power system adopted in an embodiment of the present invention includes a three-phase power supply, an input inductance L 1 , three-phase PWM rectifier bridge, three-leg inverter bridge, output inductor L 2 , electromagnetic stirrer, three-phase PWM rectifier bridge and three-arm inverter bridge are connected to form a three-phase two-phase orthogonal inverter power supply, and the switching devices in the three-phase PWM rectifier bridge and three-arm inverter circuit are IGBT or smart Power module IPM, three-phase PWM rectifier bridge via input inductance L 1 It is connected to the three-phase power supply on the grid side; the midpoint of the two bridge arms in the three-bridge inverter circuit is connected to two single-phase loads through the output inductor, and the midpoint of the third bridge arm is connected to the small inductor L 2 Connect to the ground wire of the magnetic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com