Multilayer stubble-cleaning rotary-cultivation fertilizing seeding machine

A multi-layer fertilization and seeding machine technology, which is applied to agricultural machinery and tools, shovels, plows, etc., can solve the problems that the utilization rate of water, fertilizer and fertilizer cannot be improved, the seeding depth is difficult to control, and the production efficiency and seeding quality of the planter are limited. Improve water and fertilizer absorption and stress resistance, increase root activity and hormone production capacity, improve technology integration and effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

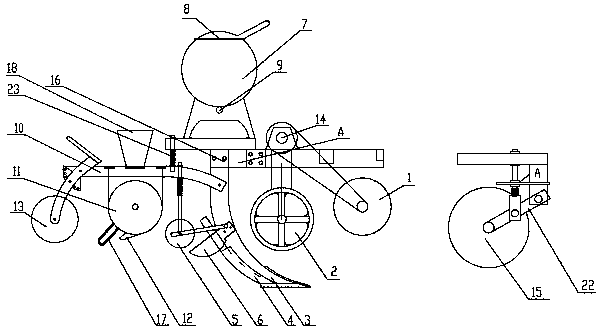

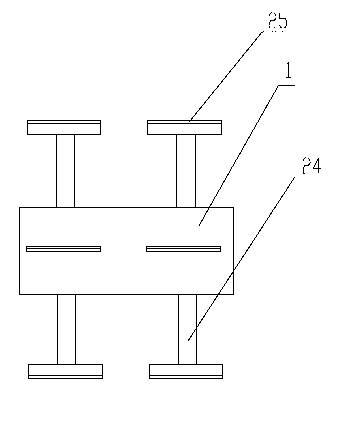

[0025] Such as Figure 1-2 As shown, a stubble removal rotary tillage multi-layer fertilization seeder includes a gearbox 14, a main frame 16, and a fertilization device assembly. Rotary cultivator shaft assembly 2, profiling ground wheel assembly 15, arc-shaped subsoiling knife and layered fertilizer applicator assembly, wheel-type suppression ditch opener assembly and planting device assembly, seed row stubble removal knife shaft assembly The cutter shaft of 1 and the cutter shaft of the disc rotary tiller shaft assembly 2 are connected with the gearbox 14, and the profiling ground wheel assembly 15 is the fertilizer applicator in the fertilization device assembly and the seed metering device on the sowing device assembly Power is provided, and the profiling ground wheel assembly 15 is fixed on the A place of the main frame 16 .

[0026] The planter also includes an equal-thickness soil-covering suppression device 13 fixed on the left side of the seeder profiling frame 10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com