Control device for vehicle electric drive motor and vehicle with the same

A technology for vehicle driving and control devices, which is applied in battery/fuel cell control devices, control devices, electric vehicles, etc., and can solve problems such as difficulty in coping, reducing exhaust environmental protection, and inability to deal with it.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

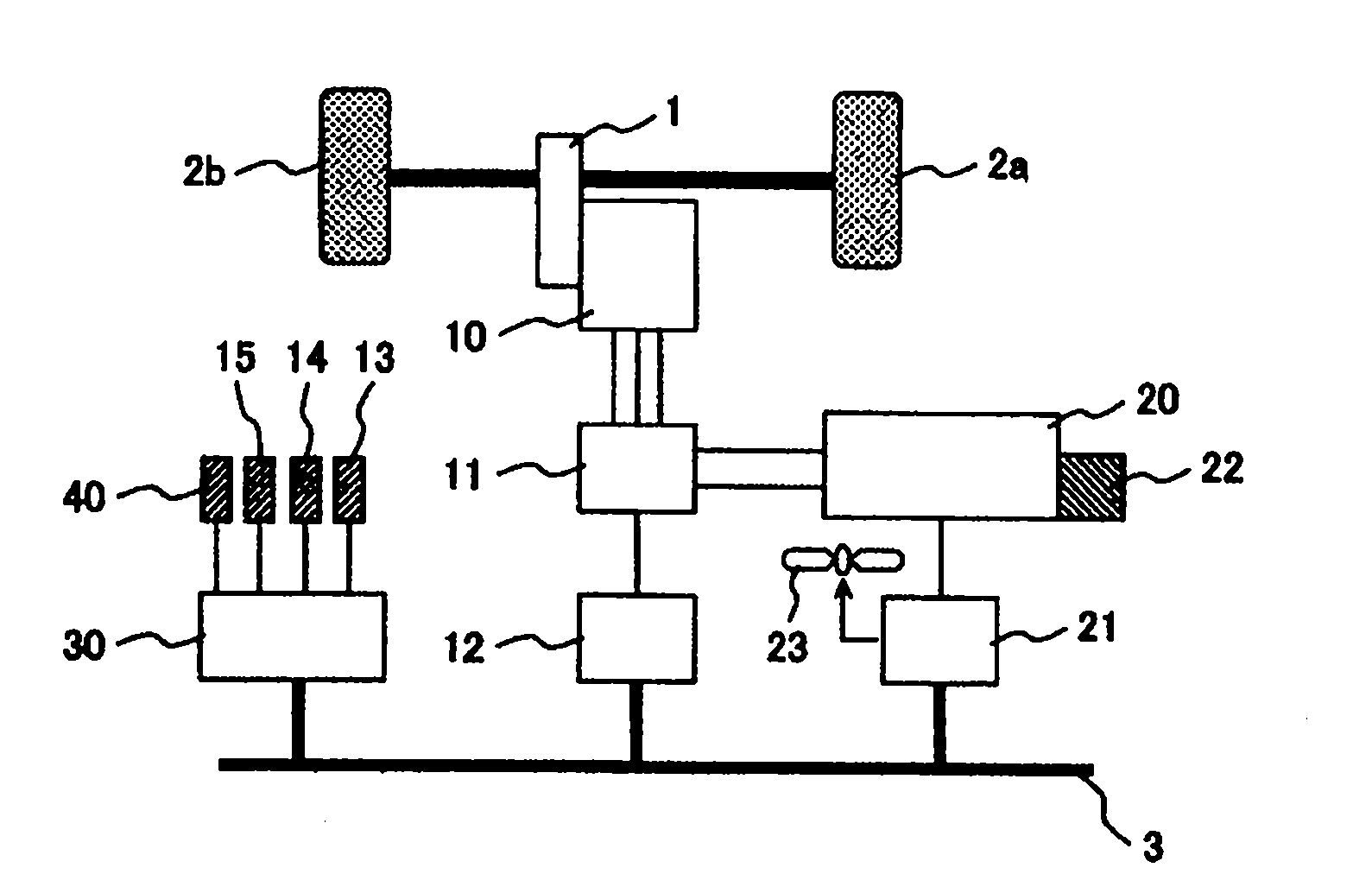

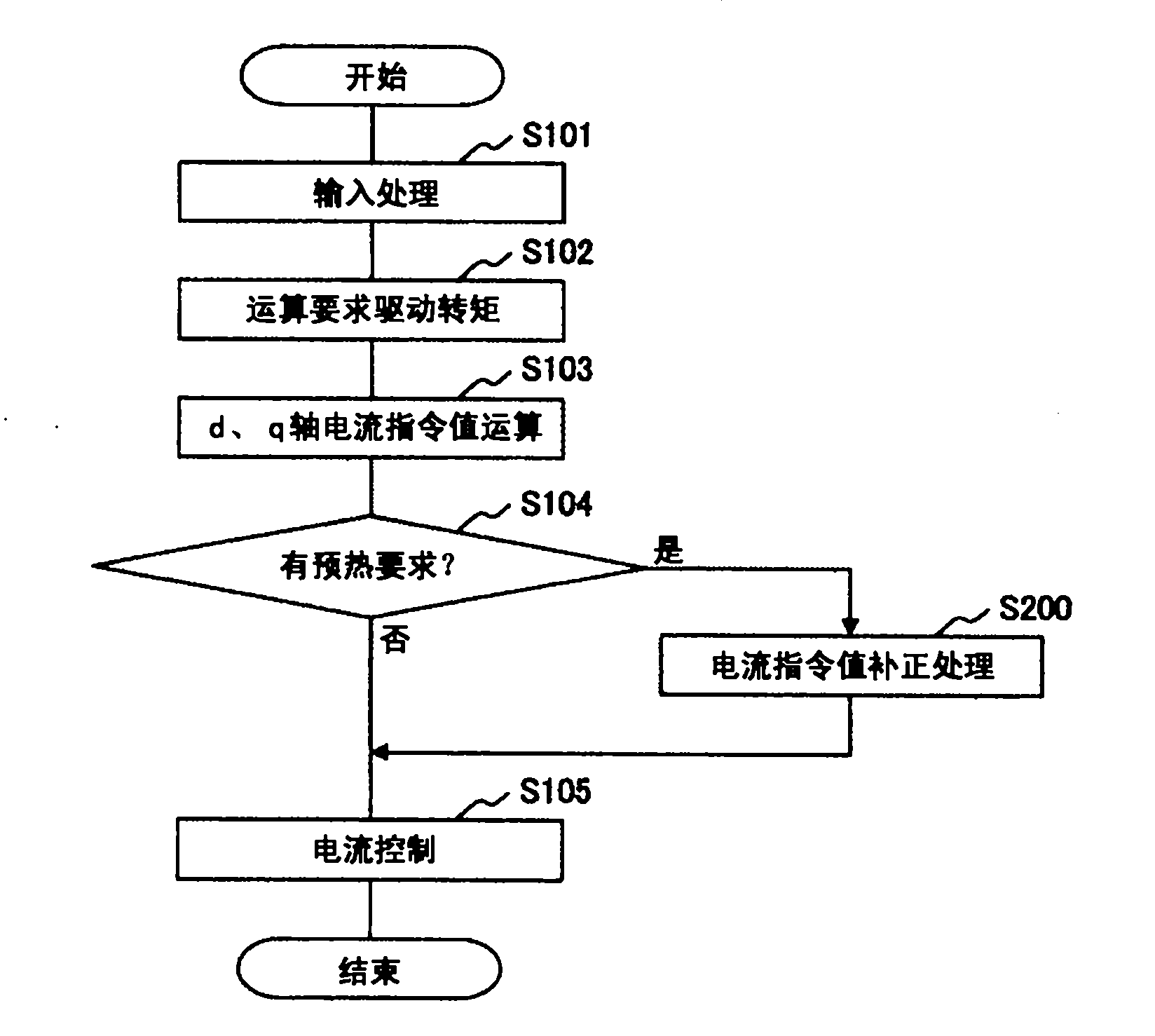

[0029] figure 1 It is a schematic diagram of a vehicle equipped with a motor control device according to the first embodiment of the present invention, and as an example, a schematic diagram of an electric vehicle having a driving motor 10 for vehicle running as a driving source is shown.

[0030] figure 1 The vehicle according to the embodiment has the following configuration as an ECU (Electronic Control Unit): a battery ECU 21; a motor ECU (motor control unit) 12 that controls the motor 10; and a vehicle ECU 30 that controls the entire vehicle. . The battery ECU 21 calculates the inter-terminal voltage of the battery 20 serving as the power supply for the vehicle, the charging and discharging current, and the accumulated state of charge (SOC) based on the charging and discharging current, or obtains the battery temperature generated by the battery temperature sensor 22, etc., and performs Management of the battery 20 such as charging and discharging current. In addition,...

Embodiment 2

[0066] Image 6 It is a schematic diagram of a vehicle equipped with a motor control device according to a second embodiment of the present invention. In the embodiment, not only the self-heating of the battery with d-axis current and q-axis current can be used, but also the heat generated by the motor or inverter can be used to preheat the battery.

[0067] about Image 6 added to the composition of figure 1 Parts with the same symbols have the same functions, and therefore descriptions thereof are omitted. In this example, figure 1 The vehicle of this invention is provided with the same battery ECU21, motor ECU12, and vehicle ECU30 as the first embodiment.

[0068] In this embodiment, not only the battery warm-up based on the self-heating of the battery using the d-axis current and q-axis current as in the first embodiment is performed, but also the heat generated in the vehicle drive motor 10 or the inverter 11 is passed through The cooling water and air are moved to t...

Embodiment 3

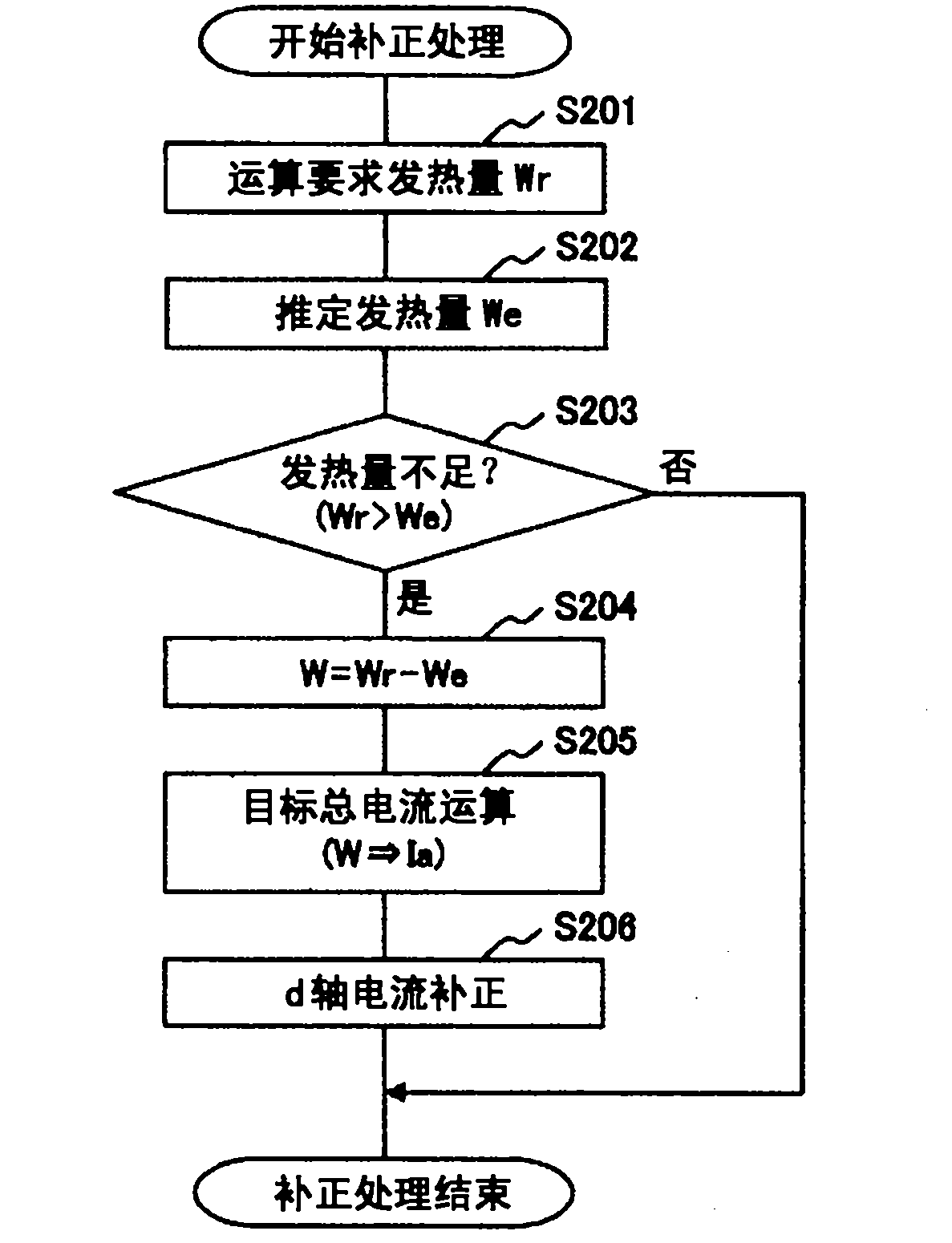

[0083] Figure 7 It is a flowchart showing motor current control during battery warm-up operation applied to the vehicle according to the third embodiment of the present invention.

[0084] The vehicle configuration of this embodiment is the same as that of the first embodiment, and d-axis current control and q-axis current control are performed based on the battery temperature and the required drive torque signal during warm-up operation as in the first embodiment, However, the difference from the first embodiment is that when the vehicle is stopped, the motor ECU 12 not only performs the warm-up operation of the d-axis current, but also does not make the q-axis current zero, but is set so that when the brake is released, the vehicle can be activated. The q-axis current value of the driving torque for creeping.

[0085] In the following, for such motor control, the Figure 7 The flow chart is described. exist Figure 7 In the flow chart, with image 3 In the shown flowch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com