Low-temperature heatless vacuum salt making device

A thermal vacuum and low temperature technology, applied in the direction of alkali metal chloride, etc., can solve the problems of high energy consumption of mechanical compression heat pumps, the inability to realize free adjustment and reduction, and the need to stop production of the whole machine for maintenance, so as to prolong the use and maintenance costs, and huge Economic and social benefits, the effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

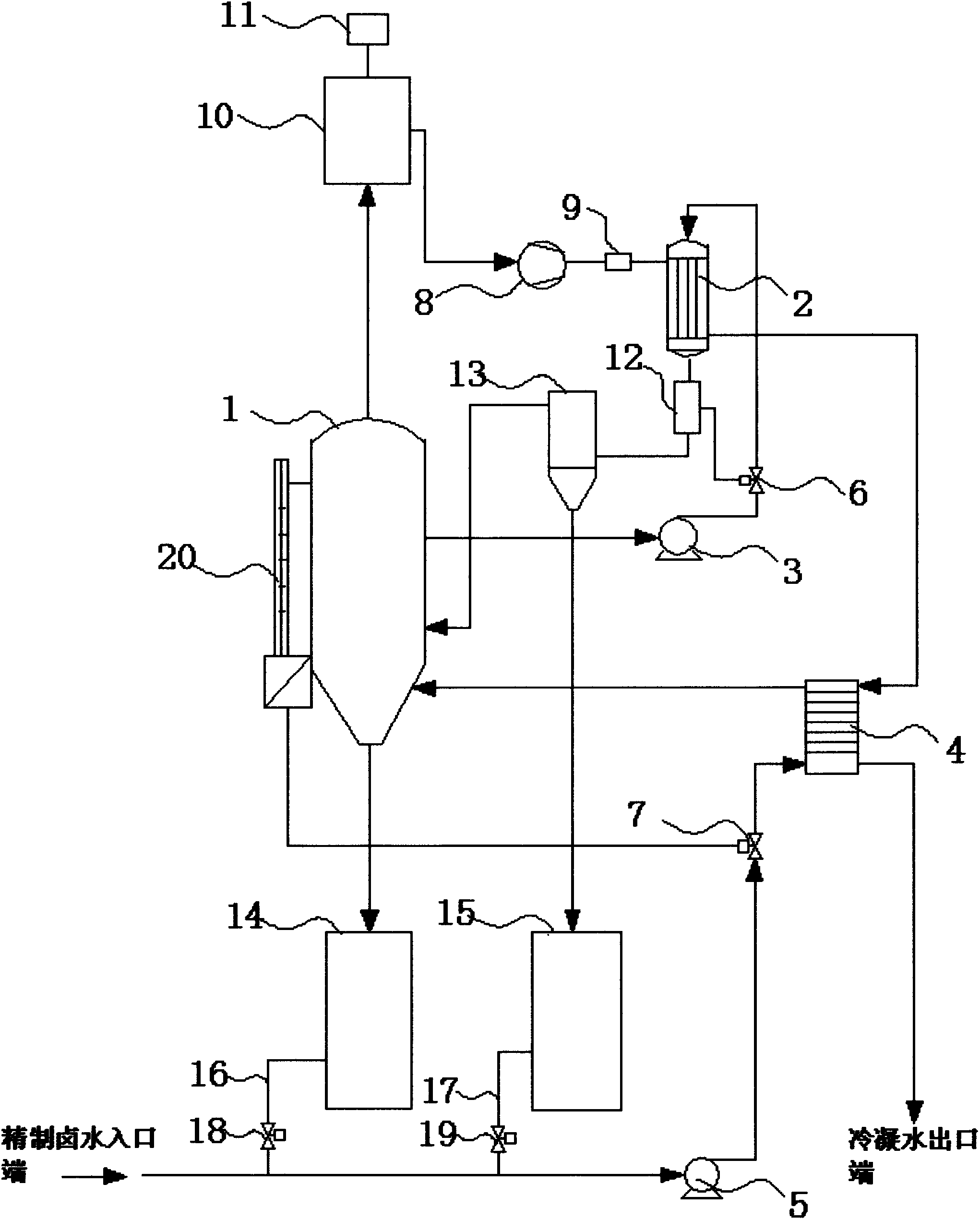

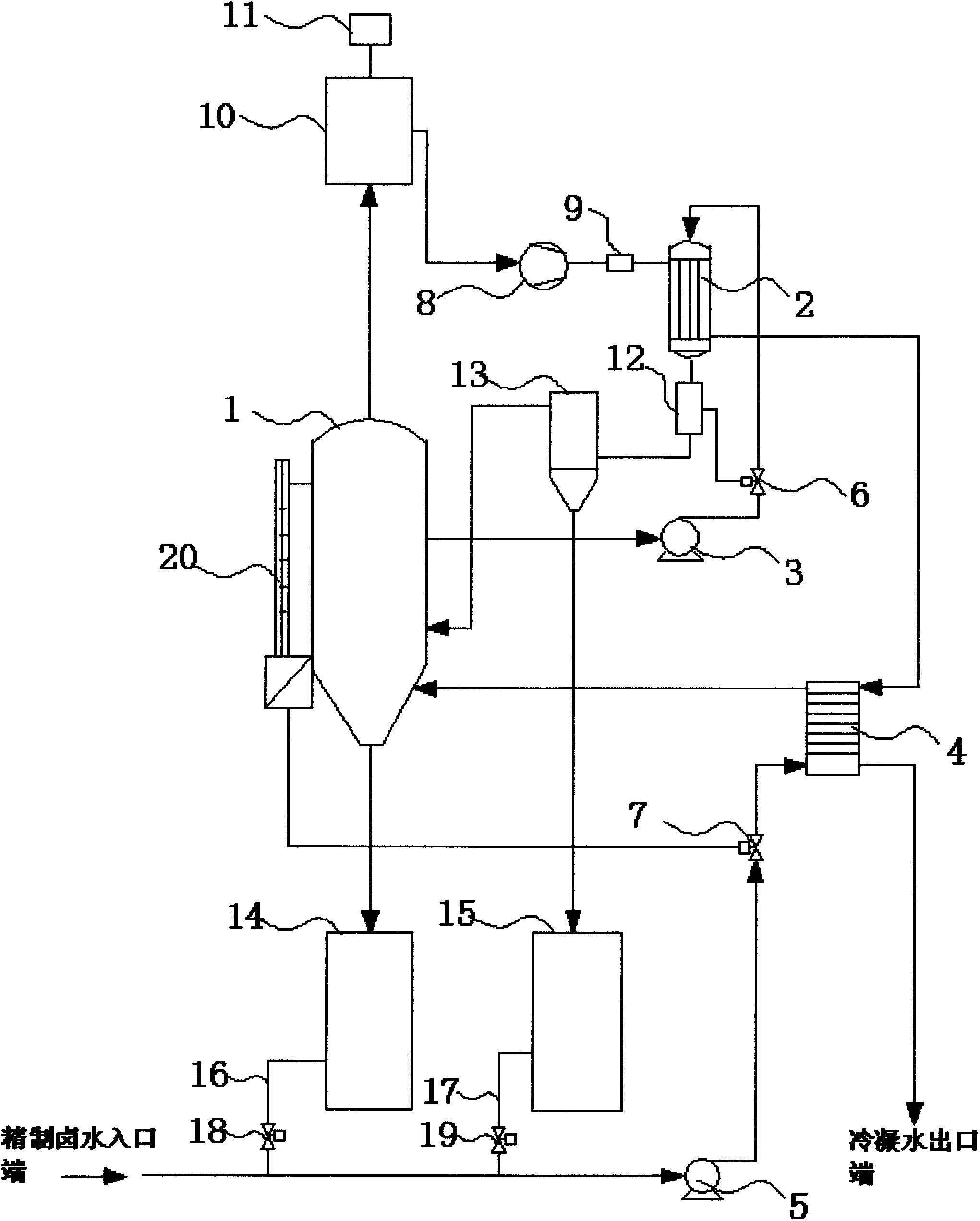

[0027] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

[0028] Such as figure 1 As shown, a low-temperature heatless vacuum salt-making device includes: an evaporation system consisting of an evaporation tank 1, a heat exchanger 2, and a forced evaporation circulation pump 3 arranged between the evaporation tank and the heat exchanger, brine Preheater 4 is formed, because this device adopts single-effect evaporation, so the diameter of evaporating pot is selected larger, and the diameter selected in the present embodiment is controlled at about 2m, and described brine preheater 4 is also provided with a condensed water outlet, and described A brine pump 5 is provided at the inlet end of the brine preheater, and a first electric regulating valve 6 is provided on the pipeline between the outlet of the forced evaporation circulation pump and the inlet of the heat exchanger, and the pipe between the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com