ABS / attapulgite composite material and preparation method thereof

A technology of attapulgite and composite materials, which is applied in the field of ABS/attapulgite composite materials and their preparation, and can solve the problems of unfavorable market promotion and application of ABS/PMMA composite materials, high preparation cost and high price of ABS/PMMA composite materials, etc. problems, to achieve good environmental benefits and social value, good hardness, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

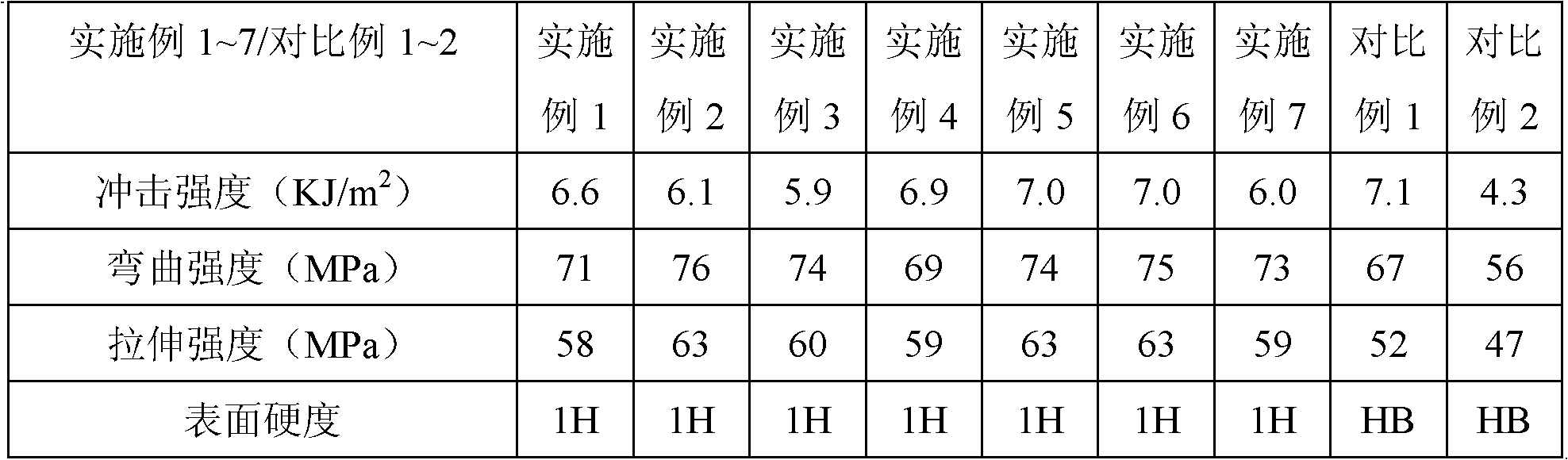

Examples

Embodiment 1

[0045] 1) Vacuum drying the attapulgite (200 mesh, Jingyuan, Gansu) at 80°C for 4 hours to obtain the dried attapulgite;

[0046] 2) Weigh 6.5 kg of ABS (Toray, Japan, T-300, melt index is 10), 2.5 kg of dried attapulgite and maleic anhydride grafted polypropylene (353D, DuPont, USA, grafting rate 1.0) 1.0 kilograms are premixed in a premixer (200 revs / min) to obtain a mixed material;

[0047] 3) Adding the mixed materials into a twin-screw extruder for melt blending, extruding and granulating to obtain a granular ABS / attapulgite composite material. Among them, the temperature of each section of the mixed material in the twin-screw extruder is respectively: the temperature of the feeding section is 210°C, the temperature of the compression section is 220°C, the temperature of the metering section is 225°C, the temperature of the head is 225°C, the speed of the twin-screw extruder is 300 rpm. The screw length-to-diameter ratio of the twin-screw extruder was 40:1.

[0048] Th...

Embodiment 2

[0050] 1) Vacuum drying the attapulgite (200 mesh, Jingyuan, Gansu) at 80°C for 4 hours to obtain the dried attapulgite;

[0051] 2) Weigh 6.5 kilograms of ABS (Toray, Japan, T-300, melt index is 10), 3.0 kilograms of dried attapulgite and maleic anhydride grafted polypropylene (353D, DuPont, USA, graft ratio 1.0) respectively 0.5 kilograms are premixed in a premixer (200 revs / min), to obtain a mixed material;

[0052] 3) Adding the mixed materials into a twin-screw extruder for melt blending, extruding and granulating to obtain a granular ABS / attapulgite composite material. Among them, the temperature of each section of the mixed material in the twin-screw extruder is respectively: the temperature of the feeding section is 210°C, the temperature of the compression section is 220°C, the temperature of the metering section is 225°C, the temperature of the head is 225°C, the speed of the twin-screw extruder is 300 rpm. The screw length-to-diameter ratio of the twin-screw extru...

Embodiment 3

[0055] 1) Vacuum drying the attapulgite (200 mesh, Jingyuan, Gansu) at 80°C for 4 hours to obtain the dried attapulgite;

[0056] 2) Weigh 6.5 kilograms of ABS (Toray, Japan, T-300, melt index is 10), 3.2 kilograms of dried attapulgite and maleic anhydride grafted polypropylene (353D, Dupont, USA, grafting rate 1.0) respectively 0.3 kilograms are premixed in a premixer (200 revs / min) to obtain a mixed material;

[0057] 3) Adding the mixed materials into a twin-screw extruder for melt blending, extruding and granulating to obtain a granular ABS / attapulgite composite material. Among them, the temperature of each section of the mixed material in the twin-screw extruder is respectively: the temperature of the feeding section is 210°C, the temperature of the compression section is 220°C, the temperature of the metering section is 225°C, the temperature of the head is 225°C, the speed of the twin-screw extruder is 300 rpm. The screw length-to-diameter ratio of the twin-screw extr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com