Novel roller bit sealing ring

A technology of roller cone bits and sealing rings, applied in the field of bearing sealing, which can solve the problems of large frictional resistance, high heat rise, difficulty in meeting service life requirements, etc., and achieve the effect of reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

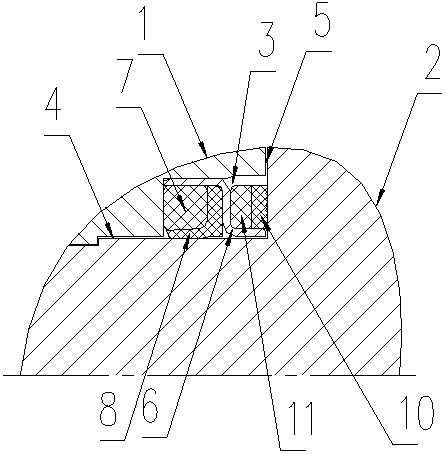

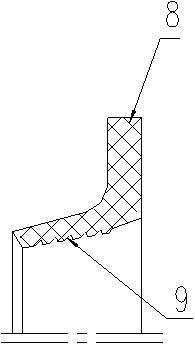

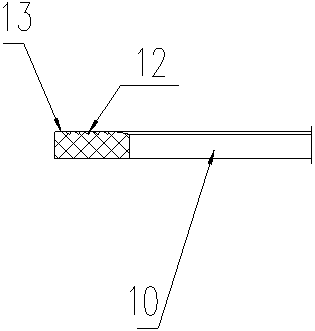

[0029] Such as Figure 1 to Figure 3As shown, a roller cone bit sealing ring is arranged in the sealing groove 3 between the cone shaft hole 1 and the palm journal 2, and the two ends of the sealing groove are connected to the internal lubricating oil channel 4 and the external drilling fluid channel respectively. 5. It includes a metal skeleton 6 fixed in the sealing groove 3, and the metal skeleton 6 separates the sealing groove 3 into a lubricating oil sealing groove communicating with the internal lubricating oil passage 4 and a drilling fluid sealing groove communicating with the external drilling fluid passage 5 The lubricating oil seal groove is provided with a lubricating oil seal, which completely seals and isolates the internal lubricating oil passage 4 together with the metal skeleton 6, and the drilling fluid seal is provided in the drilling fluid sealing groove, which is connected to the metal frame 6 The skeleton 6 together completely seals off the external drill...

Embodiment 2

[0031] Such as Figure 4 As shown, in this embodiment, when the lubricating oil pressure is less than 1MPa, the structure can be adjusted appropriately. The lubricating oil seal is composed of the radial dynamic seal 14 that dynamically seals the axial surface of the journal 2 of the tooth palm and the It is composed of a fixing piece fixed with the metal skeleton 6, and the fixing piece is composed of a metal fixing piece 15 and a rubber gasket 16. The metal fixing piece 15 is pressed against the radial dynamic seal 14 through the crimping of the metal skeleton 6, and the metal skeleton 6 is crimped. At this time, the force is transmitted to the rubber gasket 16 through the metal fixing piece 15 and the radial dynamic seal 14, so that it is compressed, and the lubricating oil leaking from between the metal fixing piece 15 and the rubber gasket 16 can be sealed. The radial dynamic seal 14 is made of filled polytetrafluoroethylene. Similarly, the dynamic sealing contact surface...

Embodiment 3

[0033] Such as Figure 5 As shown, in this embodiment, when the lubricating oil pressure is less than 1MPa, the structure can be adjusted appropriately. The lubricating oil seal is a conventional high-pressure rubber oil seal 17 made of rubber, and the others are the same as in Embodiment 1. . The high-pressure rubber oil seal 17 is a high-pressure resistant oil seal structure, which has been widely used in other fields. The purpose mentioned here is to show that all combined sealing methods that adopt the principle of fluid dynamic pressure sealing inside and outside and are similar to the present invention should be protected by patents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com