Experimental device and method for thick oil water thermal-catalytic cracking under effect of low frequency vibration waves

A low-frequency vibration, experimental device technology, applied in earthwork drilling, fluid extraction, measurement, etc., can solve the problems of small action radius, catalyst cannot contact heavy oil, and high viscosity recovery rate of heavy oil, and achieves enlarged action radius and practical value. High, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

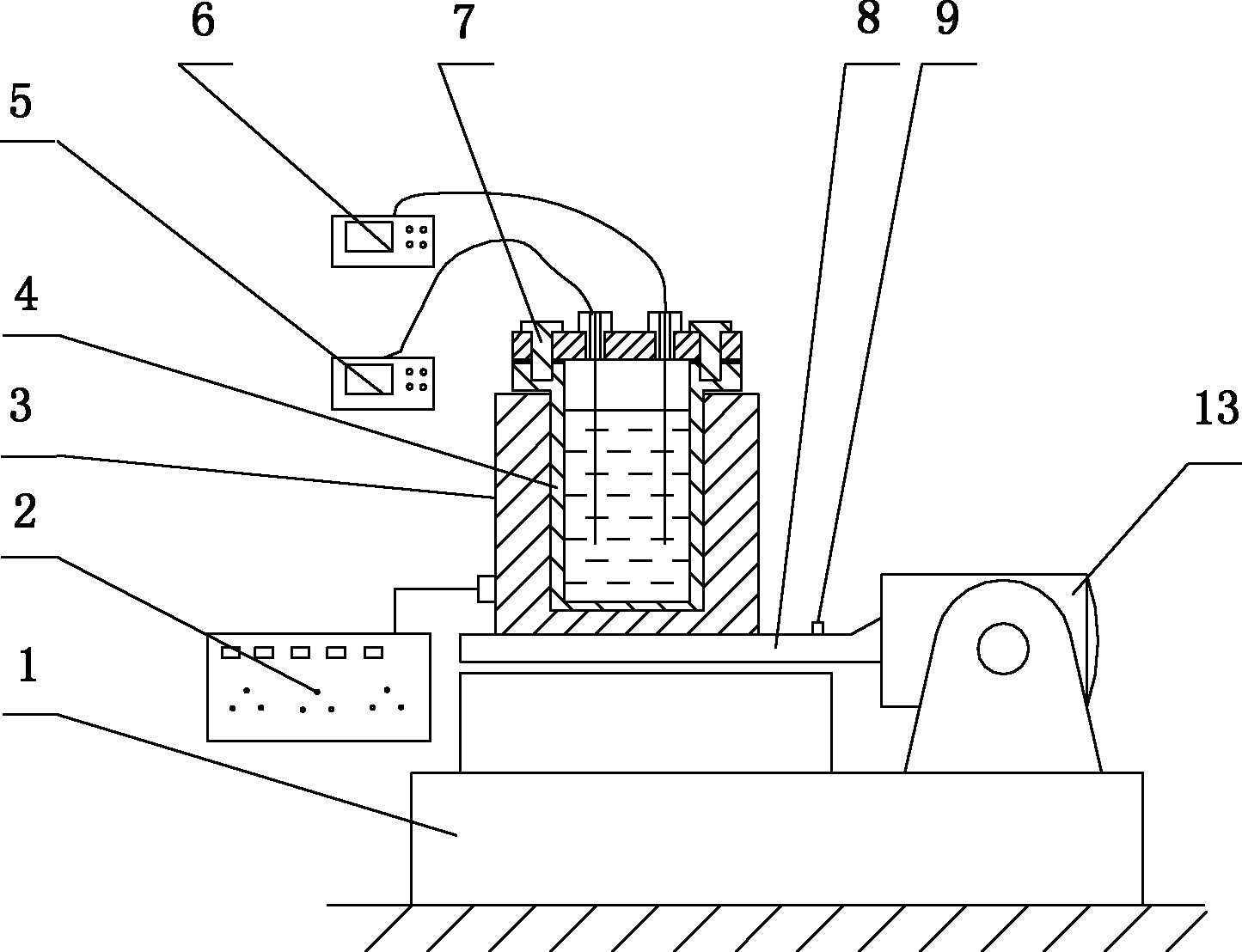

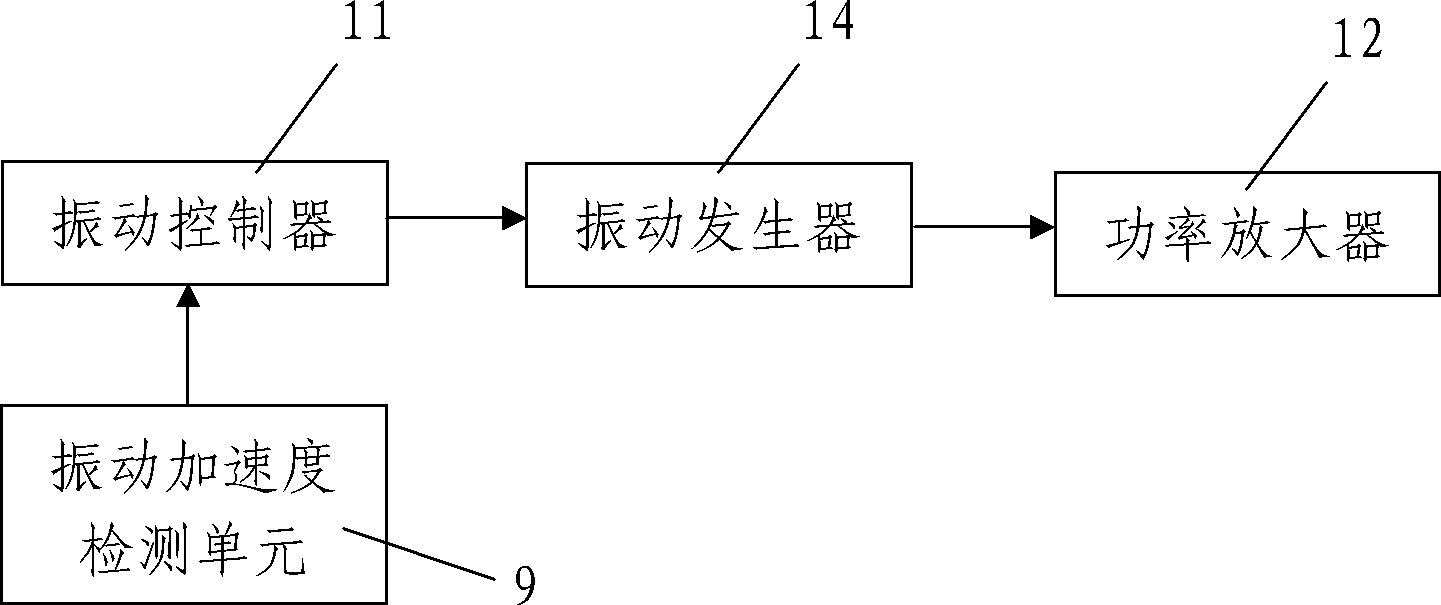

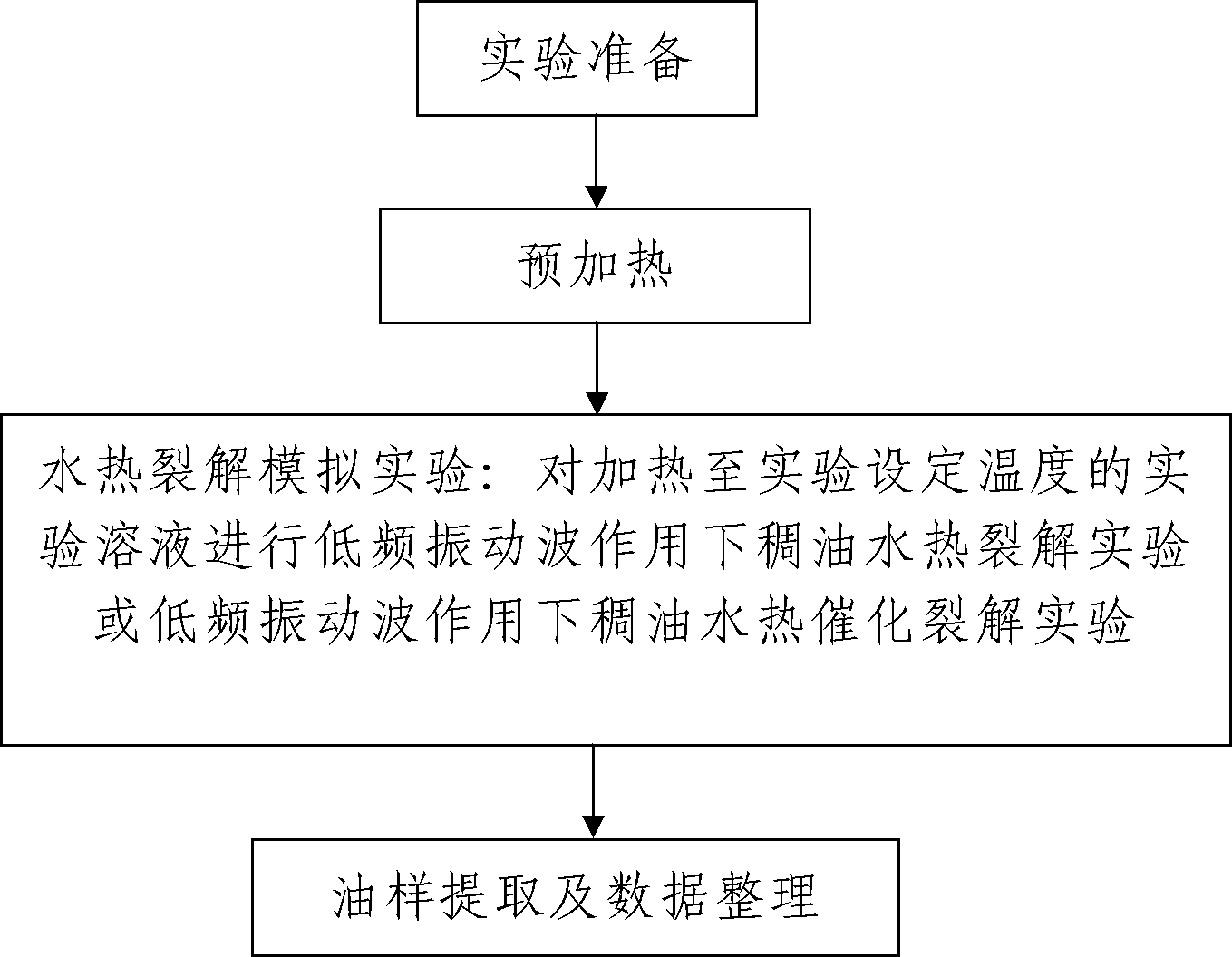

[0043] Such as figure 1 , figure 2 A hydrothermal catalytic cracking experimental device for heavy oil under the action of low-frequency vibration waves is shown, including a constant temperature heating device, a reaction tank 4 with an experimental solution inside, and a temperature detection device for real-time detection of the temperature of the experimental solution contained in the reaction tank 4 Unit 6, the pressure detection unit 5 for real-time detection of the liquid pressure of the experimental solution contained in the reaction tank 4, the electric vibration test bench that drives the reaction tank 4 to continuously vibrate up and down together with the constant temperature heating device, and the electric vibration The vibration acceleration detection unit 9 for real-time detection of the vibration acceleration of the test bench. The reaction tank 4 is placed in the constant temperature heating device and is assembled with the constant temperature heating devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com