Discontinuous rotation surface cast iron inlaying ring

A rotary surface, non-continuous technology, applied in the direction of engine components, machines/engines, pistons, etc., can solve the problem of poor ability of cast iron inserts to resist tangential machining forces, looseness of cast iron inserts and aluminum pistons, and piston ring lands Fracture and other problems, to reduce the temperature, reduce the possibility of failure, reduce the effect of non-conforming products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific diagrams.

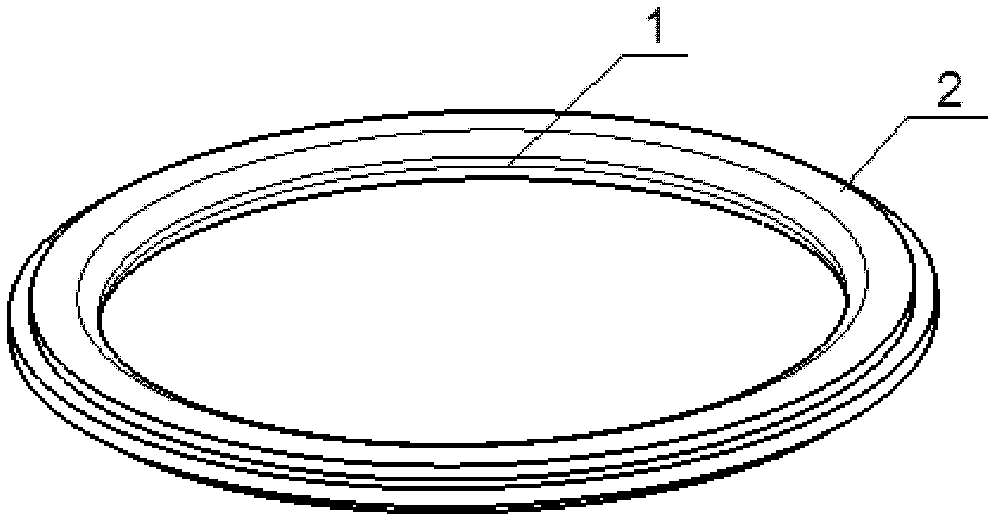

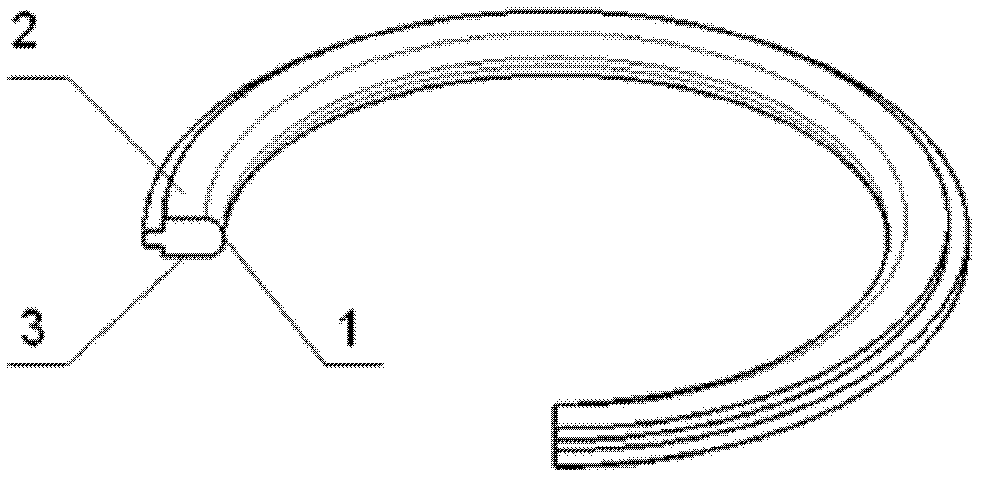

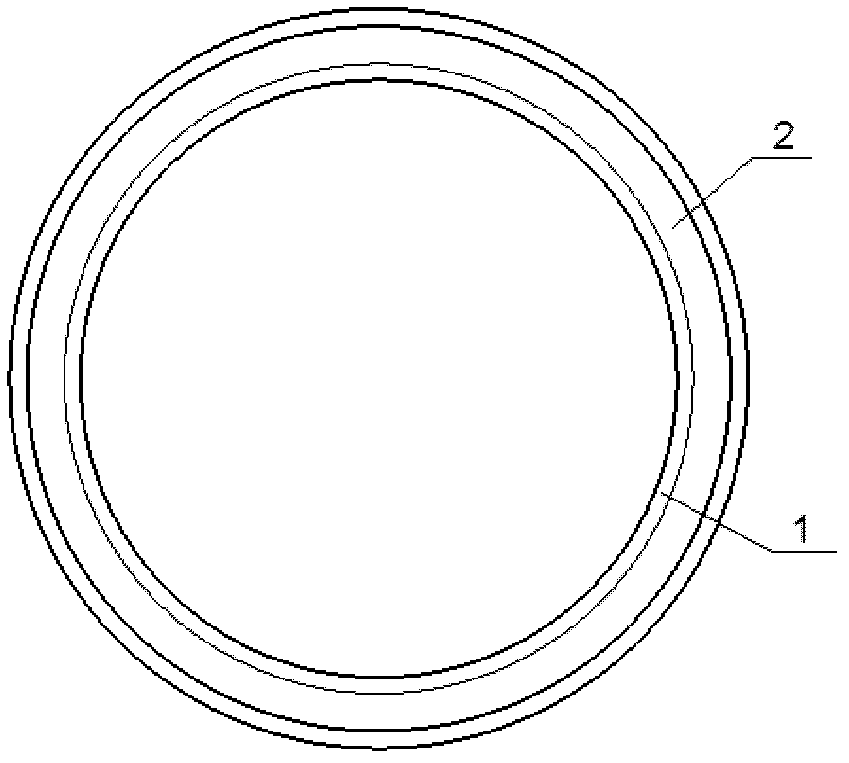

[0041] refer to Figure 3 to Figure 22 , the non-continuous rotary surface cast iron insert includes a main body of the insert, the main body of the insert is in the shape of a ring, and the inner surface of the main body of the insert is a discontinuous rotary surface. The inner surface of the main body of the ring is provided with protrusions or grooves, or in undulating waves.

[0042] The upper side of the ring main body is a discontinuous surface of revolution. Preferably, the upper side of the ring main body is provided with protrusions or grooves, or is undulating and wavy.

[0043] The lower side of the ring main body is a discontinuous surface of revolution. Preferably, the lower side of the main body of the ring is provided with protrusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com