Vacuum drying device and vacuum drying control method

A technology of vacuum drying equipment and drying chamber, which is used in drying solid materials, drying gas arrangement, lighting and heating equipment, etc., can solve the complicated manufacturing and maintenance of vacuum drying equipment, fail to protect vacuum pump, destroy system vacuum degree, etc. problem, to achieve the effect of large amount of use, wide range of uses, and many models

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

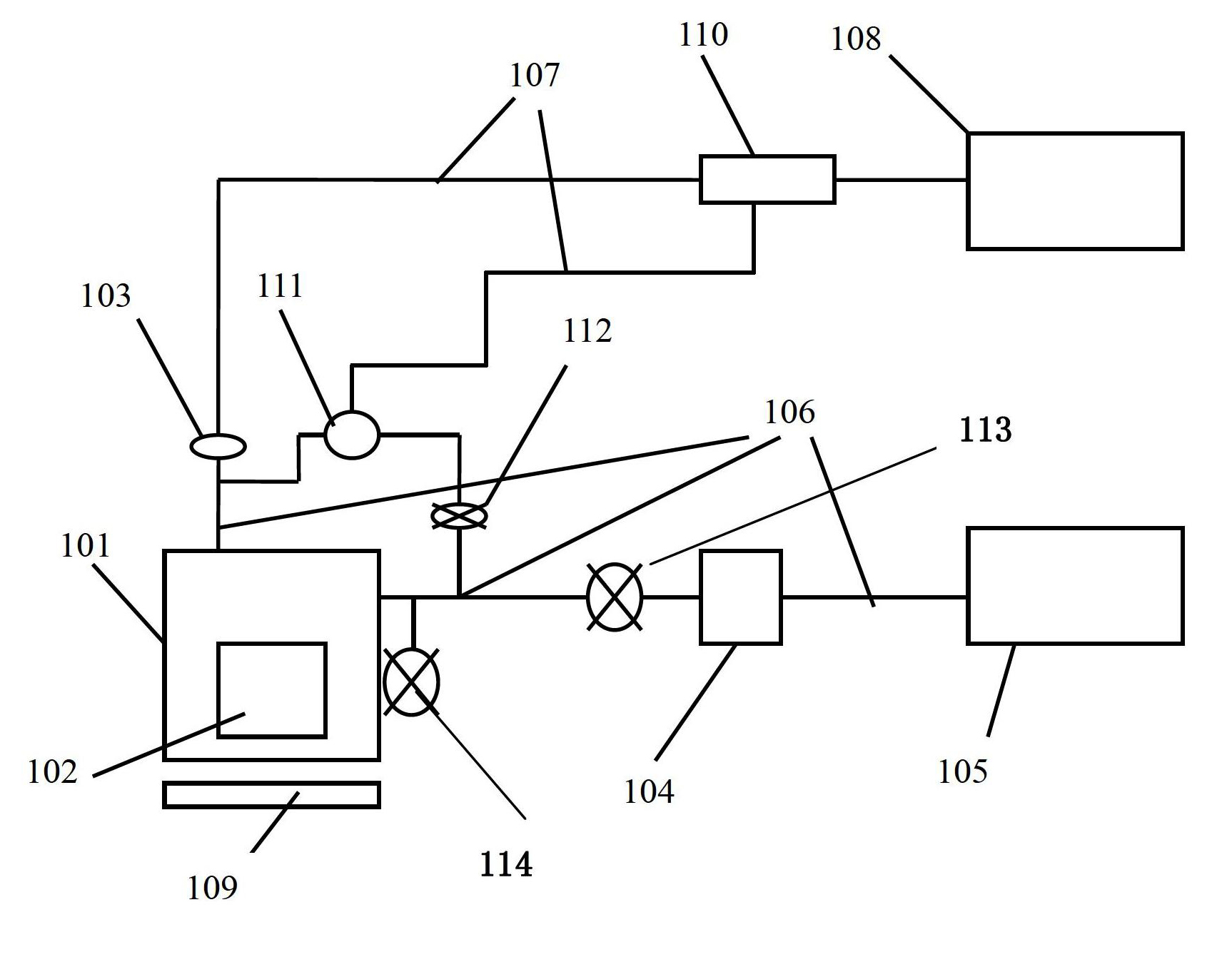

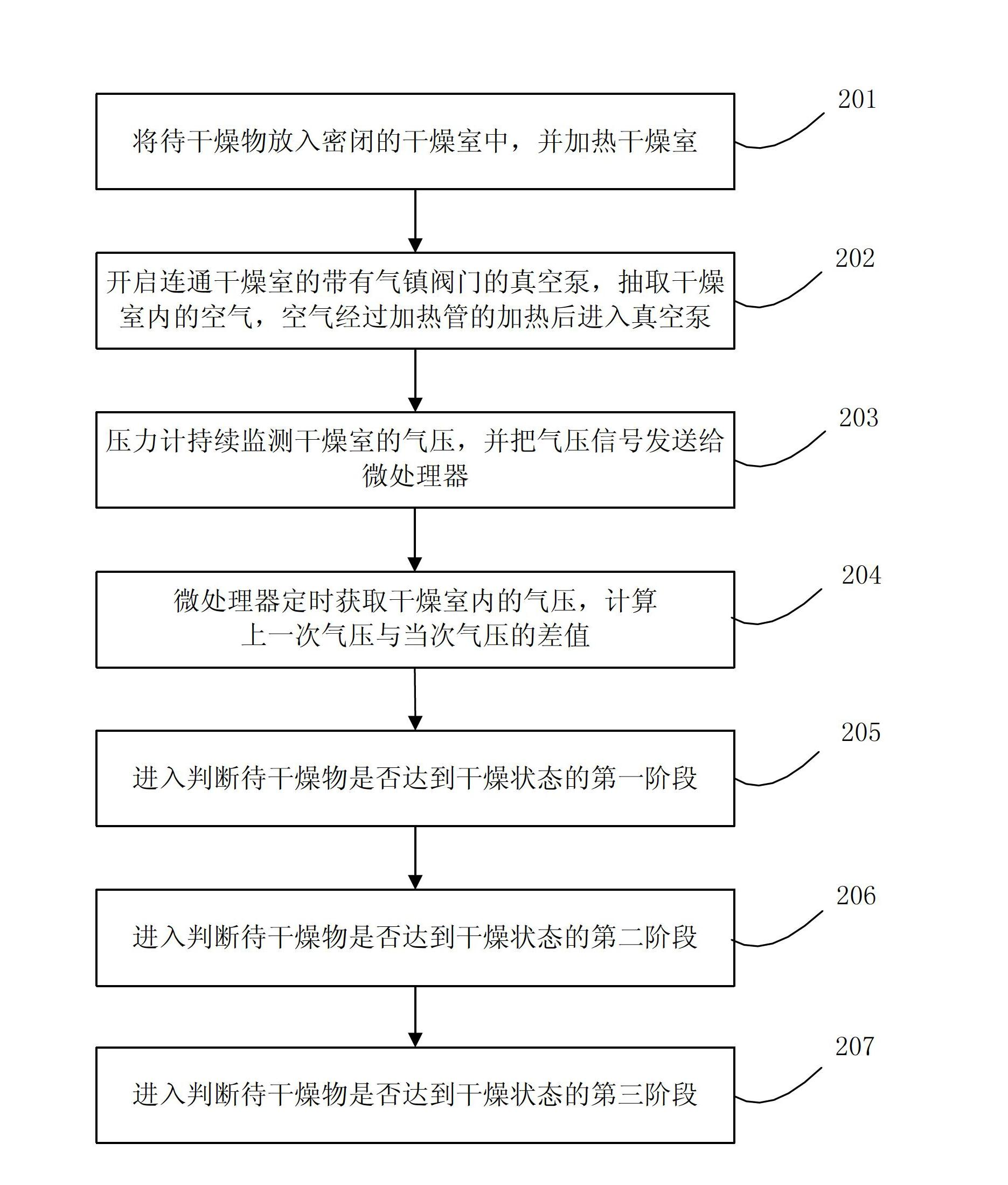

[0026] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

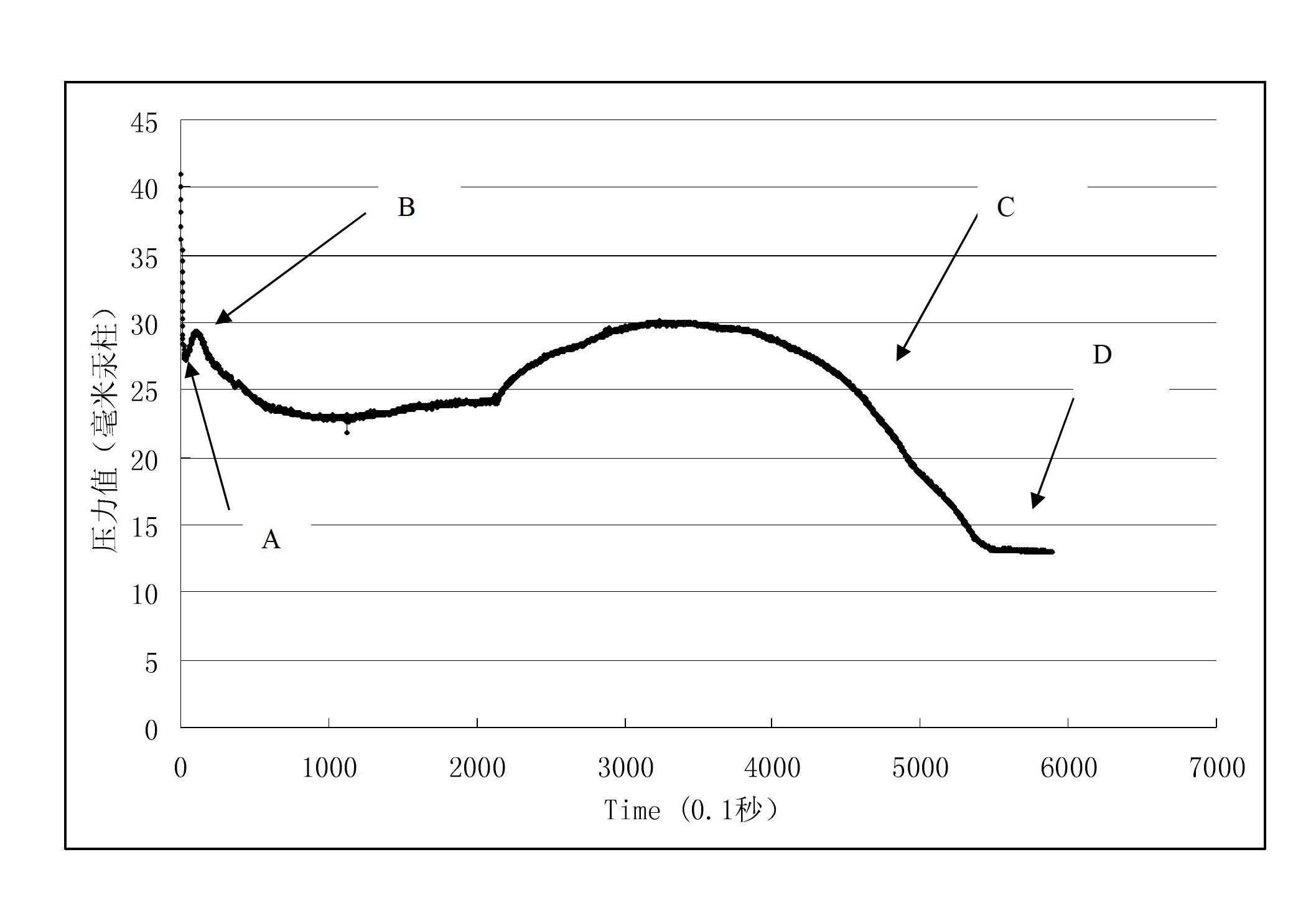

[0027] The main idea of the technical solution of the present invention is to sense the drying state of the object to be dried by measuring the change of the pressure in the vacuum drying chamber, instead of judging the drying state by an artificially set specific value. The pressure in the vacuum drying chamber is the The dynamic balance between the pressure change and the pumping speed of the vacuum pump produced when the water evaporates. When the object to be dried has not been dried, the water in the object to be dried evaporates into a gaseous state, which will increase the pressure in the vacuum drying chamber. When the object to be dried is dried, the water will no longer evaporate, and the pressure in the vacuum drying chamber will drop rapidly. Therefore, by measuring the pressure change...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com